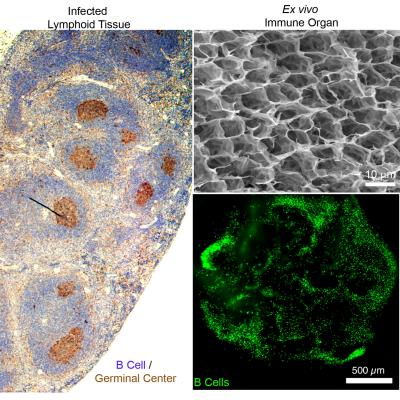

When exposed to a foreign agent, such as an immunogenic protein, B cells in lymphoid organs undergo germinal center reactions. The image on the left is an immunized mouse spleen with activated B cells (brown) that produce antibodies. At right, top: a scanning electron micrograph of porous synthetic immune organs that enable rapid proliferation and activation of B cells into antibody-producing cells. At right, bottom: primary B cell viability and distribution is visible 24 hours following encapsulation procedure.

Credit: Singh Lab

The first-of-its-kind immune organoid was created in the lab of Ankur Singh, assistant professor of mechanical and aerospace engineering, who applies engineering principles to the study and manipulation of the human immune system. The work was published online June 3 in Biomaterials and will appear later in print.

Study PDF and images: https:/

The synthetic organ is bio-inspired by secondary immune organs like the lymph node or spleen. It is made from gelatin-based biomaterials reinforced with nanoparticles and seeded with cells, and it mimics the anatomical microenvironment of lymphoid tissue.

Like a real organ, the organoid converts B cells — which make antibodies that respond to infectious invaders — into germinal centers, which are clusters of B cells that activate, mature and mutate their antibody genes when the body is under attack. Germinal centers are a sign of infection and are not present in healthy immune organs.

The engineers have demonstrated how they can control this immune response in the organ and tune how quickly the B cells proliferate, get activated and change their antibody types. According to their paper, their 3-D organ outperforms existing 2-D cultures and can produce activated B cells up to 100 times faster.

The immune organ, made of a hydrogel, is a soft, nanocomposite biomaterial. The engineers reinforced the material with silicate nanoparticles to keep the structure from melting at the physiologically relevant temperature of 98.6 degrees.

The organ could lead to increased understanding of B cell functions, an area of study that typically relies on animal models to observe how the cells develop and mature.

What's more, Singh said, the organ could be used to study specific infections and how the body produces antibodies to fight those infections — from Ebola to HIV.

'You can use our system to force the production of immunotherapeutics at much faster rates,' he said. Such a system also could be used to test toxic chemicals and environmental factors that contribute to infections or organ malfunctions.

The process of B cells becoming germinal centers is not well understood, and in fact, when the body makes mistakes in the genetic rearrangement related to this process, blood cancer can result.

'In the long run, we anticipate that the ability to drive immune reaction ex vivo at controllable rates grants us the ability to reproduce immunological events with tunable parameters for better mechanistic understanding of B cell development and generation of B cell tumors, as well as screening and translation of new classes of drugs,' Singh said.

###

The work resulted from a long-standing collaboration with hematology and medical oncology expert Dr. Leandro Cerchietti, assistant professor of medicine at Weill Cornell Medical College, and Akhilesh Gaharwar, assistant professor of biomedical engineering at Texas A&M University. The paper is titled 'Ex vivo engineering immune organoids for controlled germinal center reactions,' and its first author is Alberto Purwada, a biomedical engineering graduate student in Singh's lab. The work was supported by the National Institutes of Health, the Cornell and Weill Cornell seed grant program, and the Howard Hughes Medical Institute.