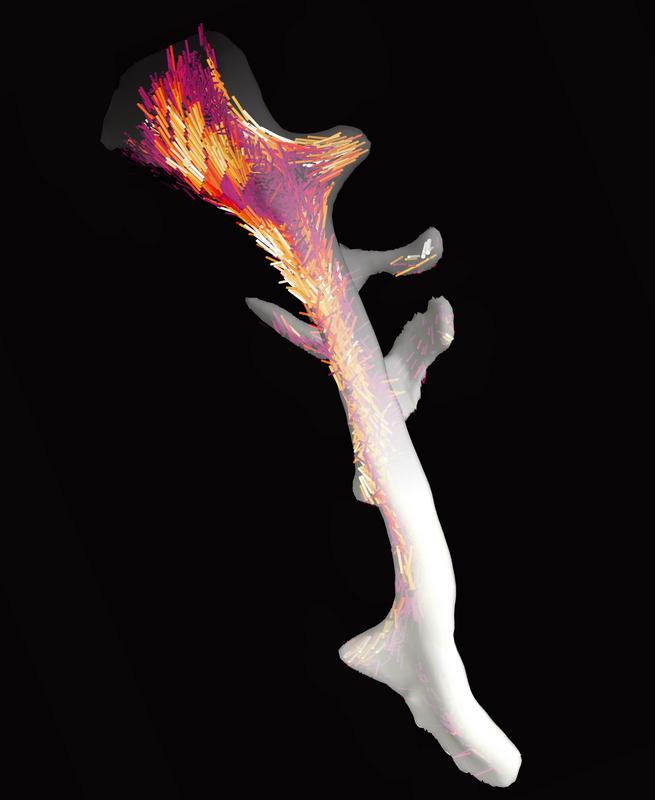

The bone and its nanostructure: Thanks to their newly developed algorithm, researchers at PSI succeeded in mapping the order and alignment of the tiny collagen fibrils.

Graphics: Paul Scherrer Institute/Marianne Liebi

The arrangement of the nanostructure of a three-dimensional object can now be visualised thanks to a new method developed by researchers at the Paul Scherrer Institute PSI.

The researchers demonstrated this new approach in collaboration with bone biomechanics experts at ETH Zurich and the University of Southampton, UK, using a small piece of a human vertebrae that was roughly two and a half millimetres long.

Bone consists of tiny fibres that are referred to as collagen fibrils. Their local three-dimensional order and alignment, which plays a central role in determining a bone’s mechanical properties, has now been visualised along the entire piece of bone.

This novel imaging approach provides important information that could aid, for example, the study of degenerative bone disease such as osteoporosis. In general, the new method is suitable not only for examining biological objects but also for developing promising new materials.

The data was obtained from PSI’s Swiss Light Source SLS, where the piece of bone was screened with an extremely fine and intense X-ray beam. This beam is scanned across the sample, recording data point by point. The interaction of the X-rays with the sample provides information about the local nanostructure at each measurement point.

The crucial step from 2D to 3D

Until now, only two-dimensional samples could be scanned and examined in this way. Traditionally, the objects examined are thus cut into very thin slices. “But not every object can be cut as thinly as you’d want”, explains project supervisor Manuel Guizar-Sicairos. “And sometimes when you cut it, you destroy or disturb the very nanostructure that you wanted to examine.” Quite generally, a non-destructive method is preferable, leaving the object intact for subsequent investigations.

In order to be able to image three-dimensional objects, the PSI researchers scanned their sample repeatedly, turning it by a small angle between each scan. This way, they obtained measurement data for all orientations that allowed them to subsequently reconstruct the three-dimensional object, including its nanostructure, on the computer.

The new measurement method used by the PSI researchers draws on a basic principle from computer tomography (CT). CT also involves first taking many X-ray images of a patient or object from different angles and then combining them to form the desired images by means of a computer calculation. However, traditional computer tomography does not use a fine X-ray beam. Instead, the object is irradiated as a whole.

While computer tomography can depict the varying density of the material, it does not capture details like the order and alignment of the underlying nanostructure. The latter only becomes possible through accurate measurement of the interaction between sample and X-rays which is enabled by the narrow, intense X-ray beam of the SLS in conjunction with state of the art detectors.

Images emerge thanks to mathematical algorithms

The most complex step was to compile a computer image of the three-dimensional sample from the vast amount of data. To do this, the researchers developed their own sophisticated mathematical algorithm. “The X-ray beam always penetrates the entire depth of the sample and we only see the end result”, explains Marianne Liebi, lead author of the study. “What the three-dimensional structure actually looks like is something we have to find out afterwards.”

For each point on the inside of the sample, Liebi’s algorithm searches for the structure that best corresponds to all the data measured. In the algorithm, the researchers took advantage of the fact that they could assume a certain symmetry in the arrangement of the collagen fibrils in the bone, thus reducing their data to a manageable level. Nevertheless, there still remained 2.2 million parameters to be found. These were optimised using a computer program that tests better and better solutions until it finds one that can best explain all measurements.

“I was amazed that after so much pure mathematics, an image emerged that really looked like a bone,” said Liebi. “The details in it were plausible right away.”

Like a map of the vegetation zones

While classic computer tomography generates greyscale images, the new method provides coloured images with considerably more information: The multi-coloured cylinders show the orientation on the nanoscale and even provide information on the degree of the orientation, which is high if adjacent collagen fibrils all have the same orientation and low if they are randomly oriented.

“We can’t image each individual collagen fibril directly, but that’s not necessary anyway”, explains Guizar-Sicairos. “Our imaging technique is akin to a map of vegetation zones. There too, one averages over certain areas, stating that one region is dominated by coniferous trees, another by deciduous trees and yet another by mixed woodland.” In this way, it is possible to map the vegetation of entire continents without having to classify every single tree.

By analogy it can be said that with traditional microscopic and nanoscopic methods this depiction of individual trees was necessary. That’s why until now, the smaller the structure of an object was the smaller the imaged section also had to be. Their new method allowed the PSI researchers to circumvent this limitation: From a piece of bone visible to the naked eye, they recorded the arrangement of the nanostructure in one single image.

At the same time as their publication, Nature will feature a second publication with research led by another researcher team with Liebi and Guizar-Sicairos as co-authors. That publication introduces an alternative algorithm that leads to a similar result: The researchers were able to determine the three-dimensional internal nanostructure of a human tooth.

Text: Paul Scherrer Institute/Laura Hennemann

About PSI

The Paul Scherrer Institute PSI develops, builds and operates large, complex research facilities and makes them available to the national and international research community. The institute's own key research priorities are in the fields of matter and materials, energy and environment and human health. PSI is committed to the training of future generations. Therefore about one quarter of our staff are post-docs, post-graduates or apprentices. Altogether PSI employs 1900 people, thus being the largest research institute in Switzerland. The annual budget amounts to approximately CHF 380 million.

Contact

Dr. Marianne Liebi, Coherent X-ray Scattering group, Laboratory for Macromolecules and Bioimaging, Paul Scherrer Institute,

telephone: +41 56 310 54 53, e-mail: marianne.liebi@psi.ch [German, English]

Dr. Manuel Guizar-Sicairos, Coherent X-ray Scattering group, Laboratory for Macromolecules and Bioimaging, Paul Scherrer Institute,

telephone: +41 56 310 34 09, e-mail: manuel.guizar-sicairos@psi.ch [English, Spanish]

Original Publications

Nanostructure surveys on macroscopic specimens by small-angle scattering tensor tomography

M. Liebi, M. Georgiadis, A. Menzel, P. Schneider, J. Kohlbrecher, O. Bunk and M. Guizar-Sicairos,

Nature 19 November 2015

DOI: http://dx.doi.org/10.1038/nature16056

Six-dimensional real and reciprocal space small-angle X-ray scattering tomography

F. Schaff, M. Bech, P. Zaslansky, C. Jud, M. Liebi, M. Guizar-Sicairos and F. Pfeiffer,

Nature 19 November 2015

DOI: http://dx.doi.org/10.1038/nature16060

http://psi.ch/YkDc Press release on PSI's website with additional pictures

http://www.psi.ch/coherent-x-ray-scattering Coherent X-ray Scattering group