Metallic glass: cracking the mystery of flaws

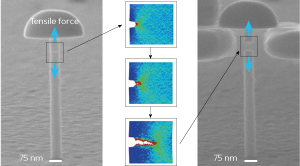

Experimental measurements (left and right) and molecular dynamics simulations (middle) of metallic glass nanopillars reveal that structural flaws play important roles in determining material strength. Copyright : Adapted by A*STAR with permission from Ref. 1. Copyright 2014 American Chemical Society.

A study from A*STAR reveals that designers of metallic-glass-based nanodevices must account for tiny flaws in alloy frameworks to avoid unpredictable catastrophic failure[1]. Understanding how nanoscale metallic glass fractures and fails when subjected to external stress is critical to improving its reliability in devices and composites.

Recently, researchers have found evidence that artificial flaws — miniscule notches carved into the alloy — do not affect the material’s overall tensile strength. But other work has shown that such notches may actually induce the formation of localized cracks.

Mehdi Jafary-Zadeh and co-workers from the A*STAR Institute of High Performance Computing, in collaboration with researchers in the United States, used a combination of physical experiments and computational simulations to study nanoscale flaw tolerance with in-depth precision.

First, the researchers fabricated nickel–phosphorous metallic glass into narrow ‘nanopillars’ bearing tiny notches and mushroom-shaped endcaps that served as tension grips (see image). Guided by high-resolution scanning electron microscopy, they systematically pulled the structures apart until they cracked — an action that consistently occurred at the notched zone, and at failure strengths 40 per cent lower than those for unflawed nanopillars.

The team then turned to massive molecular dynamics simulations to explain these physical results. “Simulating failure modes in the nanopillar metallic glasses required large-scale, three-dimensional models containing millions of atoms,” says Jafary-Zadeh. “Performing simulations at these scales is pretty daunting, but we overcame this challenge with the help of the A*STAR Computational Resource Centre.”

When the researchers modeled atomic strain during nanopillar elongation, they found that the un-notched structures failed via a plastic type of deformation known as shear banding. However, the notched structures were brittle and failed through crack propagation from the flaw point at tensile strengths significantly smaller than the un-notched samples (see video). These observations suggest that ‘flaw insensitivity’ may not be a general feature of nanoscale mechanical systems.

“The theory of flaw insensitivity postulates that the strength of materials that are intrinsically brittle or have limited plastic deformation modes approaches a theoretical limit at the nanoscale, and does not diminish due to structural flaws,” explains Jafary-Zadeh. “However, our results show that failure strength and deformation in amorphous nanosolids depend critically on the presence of flaws.”

Jafary-Zadeh notes that the excellent agreement between experimental results and the simulations is exciting and demonstrates how such computations can bridge the knowledge gap between macroscopic mechanical fracturing and the hidden corresponding mechanisms taking place at atomistic time and length scales.

The A*STAR-affiliated researchers contributing to this research are from the Institute of High Performance Computing.

Reference

1. Gu, X. W, Jafary-Zadeh, M., Chen, D. Z., Wu, Z., Zhang, Y.-W. et al. Mechanisms of failure in nanoscale metallic glass. Nano Letters 14, 5858–5864 (2014).

Associated links

http://www.research.a-star.edu.sg/research/7286

http://www.research.a-star.edu.sg/research/6667

http://www.research.a-star.edu.sg/research/6555

Media Contact

More Information:

http://www.researchsea.comAll latest news from the category: Interdisciplinary Research

News and developments from the field of interdisciplinary research.

Among other topics, you can find stimulating reports and articles related to microsystems, emotions research, futures research and stratospheric research.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…