Stanford Breakthrough: Super-Efficient Light-Based Computers

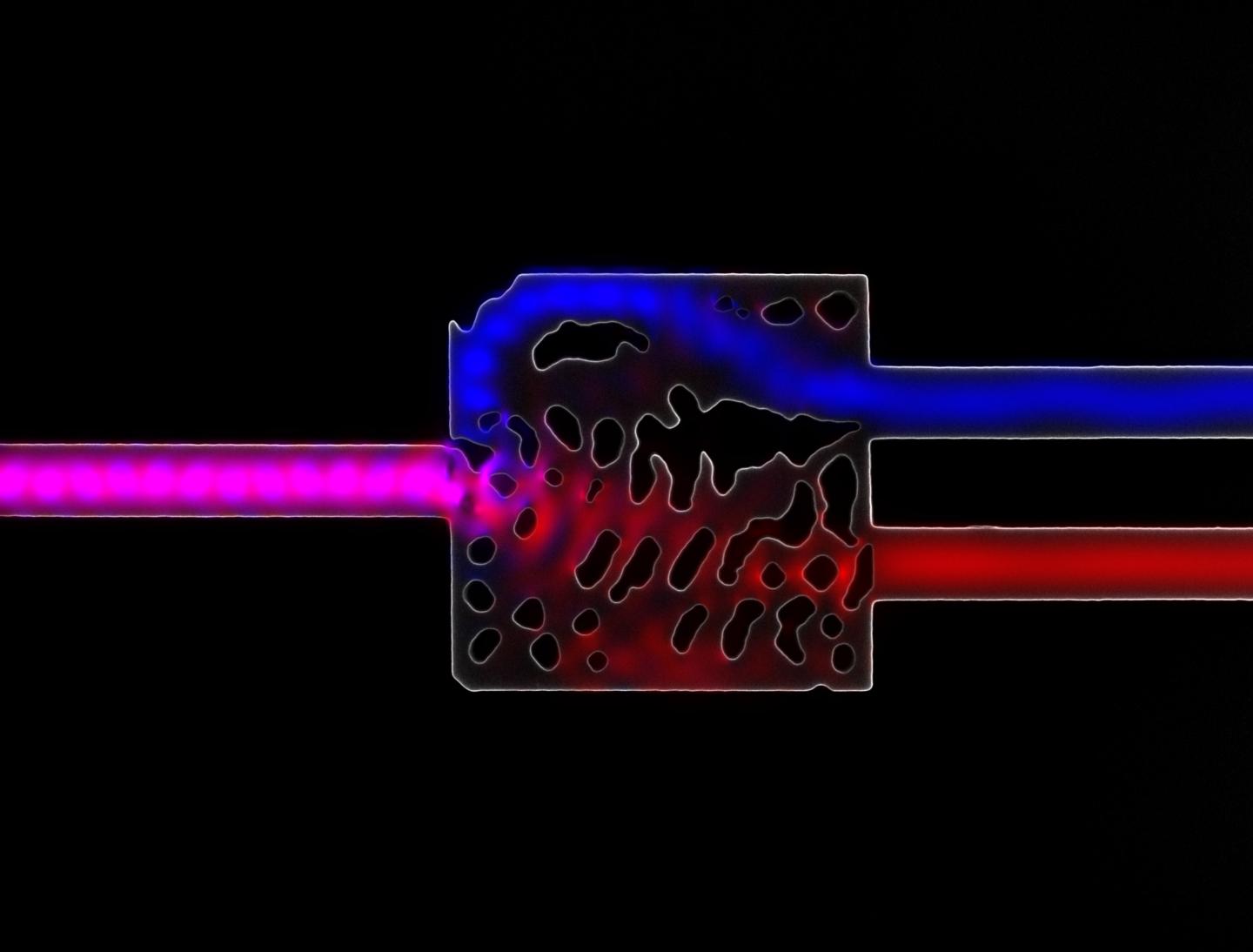

Infrared light enters this silicon structure from the left. The cut-out patterns, determined by an algorithm, route two different frequencies of this light into the pathways on the right. This is a greatly magnified image of a working device that is about the size of a speck of dust.

(Photo: Alexander Piggott)

Stanford electrical engineer Jelena Vuckovic wants to make computers faster and more efficient by reinventing how they send data back and forth between chips, where the work is done.

In computers today, data is pushed through wires as a stream of electrons. That takes a lot of power, which helps explain why laptops get so warm.

“Several years ago, my colleague David Miller carefully analyzed power consumption in computers, and the results were striking,” said Vuckovic, referring to electrical engineering Professor David Miller. “Up to 80 percent of the microprocessor power is consumed by sending data over the wires – so called interconnects.”

In a Nature Photonics article whose lead author is Stanford graduate student Alexander Piggott, Vuckovic, a professor of electrical engineering, and her team explain a process that could revolutionize computing by making it practical to use light instead of electricity to carry data inside computers.

Proven technology

In essence, the Stanford engineers want to miniaturize the proven technology of the Internet, which moves data by beaming photons of light through fiber optic threads.

“Optical transport uses far less energy than sending electrons through wires,” Piggott said. “For chip-scale links, light can carry more than 20 times as much data.”

Theoretically, this is doable because silicon is transparent to infrared light – the way glass is transparent to visible light. So wires could be replaced by optical interconnects: silicon structures designed to carry infrared light.

But so far, engineers have had to design optical interconnects one at a time. Given that thousands of such linkages are needed for each electronic system, optical data transport has remained impractical.

Now the Stanford engineers believe they've broken that bottleneck by inventing what they call an inverse design algorithm.

It works as the name suggests: the engineers specify what they want the optical circuit to do, and the software provides the details of how to fabricate a silicon structure to perform the task.

“We used the algorithm to design a working optical circuit and made several copies in our lab,” Vuckovic said.

In addition to Piggott, the research team included former graduate student Jesse Lu (now at Google,) graduate student Jan Petykiewicz and postdoctoral scholars Thomas Babinec and Konstantinos Lagoudakis. As they reported in Nature Photonics, the devices functioned flawlessly despite tiny imperfections.

“Our manufacturing processes are not nearly as precise as those at commercial fabrication plants,” Piggott said. “The fact that we could build devices this robust on our equipment tells us that this technology will be easy to mass-produce at state-of-the-art facilities.”

The researchers envision many other potential applications for their inverse design algorithm, including high bandwidth optical communications, compact microscopy systems and ultra-secure quantum communications.

Light and silicon

The Stanford work relies on the well-known fact that infrared light will pass through silicon the way sunlight shines through glass.

And just as a prism bends visible light to reveal the rainbow, different silicon structures can bend infrared light in useful ways.

The Stanford algorithm designs silicon structures so slender that more than 20 of them could sit side-by-side inside the diameter of a human hair. These silicon interconnects can direct a specific frequency of infrared light to a specific location to replace a wire.

By loading data onto these frequencies, the Stanford algorithm can create switches or conduits or whatever else is required for the task.

The inverse design algorithm is what makes optical interconnects practical by describing how to create what amount to silicon prisms to bend infrared light.

Once the algorithm has calculated the proper shape for the task, engineers can use standard industrial processes to transfer that pattern onto a slice of silicon.

“Our structures look like Swiss cheese but they work better than anything we've seen before,” Vuckovic said.

She and Piggott have made several different types of optical interconnects and they see no limits on what their inverse design algorithm can do.

In their Nature photonics paper, the Stanford authors note that the automation of large-scale circuit design enabled engineers to create today's sophisticated electronics.

By automating the process of designing optical interconnects, they feel that they have set the stage for the next generation of even faster and far more energy-efficient computers that use light rather than electricity for internal data transport.