Fraunhofer Researchers Create User-Generated Operational Aids

Fraunhofer IAO conducted a trend study to identify and examine crucial fields of action for making human-technology interaction successful in future manufacturing. The study focused on questions related to ergonomic HMI design and the integration of new technologies such as social media, interaction and recognition technologies.

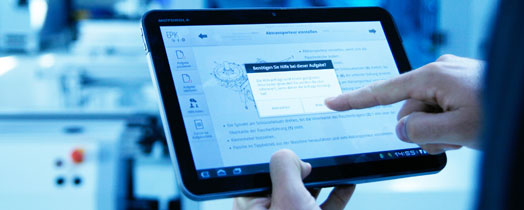

Scientists at Fraunhofer IAO set up the HMI 4.0 joint research project as a way to put their findings into practice. Under the scientific leadership of the Fraunhofer IAO, manufacturing companies, machine and plant manufacturers, system integrators and technology and software suppliers develop user-generated operational aids that they then turn into prototypes.

“We have users and experts from a wide variety of different areas on board, which helps us to approach the topic from various angles,” explains project leader Dr. Matthias Peissner of Fraunhofer IAO. The aim is to develop a system that supports users to successfully manage disruptive incidents, and to make knowledge accessible for and usable by other users.

Knowledge management with HMI 4.0

The researchers deliberately chose to focus on operational aids. “Operational aids can provide efficient support for error situations and other action areas in automated processes,” says Peissner.

In particular, the system will make it easy for employees to share their knowledge of specific error situations and thus contribute to user-generated operational aids. It will also ensure the scope, accuracy and instructive quality of operational aids and encourage employees to share what they know. To achieve this, the experts are also factoring in incentive systems at the HMI and organizational level.

The joint research project aims to address the following issues:

How can users provide their knowledge efficiently using the interface?

How can the quality of operational aids be guaranteed?

How can users be motivated to share their knowledge with others?

What do appropriate business models look like?

Dovetailing research and practical work

In addition to what they gain from the research conducted by Fraunhofer IAO, participants in the joint research project will especially benefit from the interdisciplinary and cross-industry composition of the consortium. The group includes production plant operators such as Daimler, machine manufacturers such as Oerlikon and Broetje-Automation, as well as software and technology companies such asCOPA-DATA, Getac and Siemens.

The HMI 4.0 joint research project is open to all economic partners with an interest in innovative approaches in the field of HMI design, and who are actively seeking to gain a competitive advantage.

Contact:

Dr. Matthias Peissner

Fraunhofer IAO

Nobelstraße 12

70569 Stuttgart, Germany

Phone: +49 711 970-2311

E-Mail: matthias.peissner@iao.fraunhofer.de

David Blank

Fraunhofer IAO

Nobelstraße 12

70569 Stuttgart, Germany

Phone: +49 711 970-2321

E-Mail: david.blank@iao.fraunhofer.de

http://www.iao.fraunhofer.de/lang-en/business-areas/information-communication-te…

http://www.hci.iao.fraunhofer.de/de/projekte/industrieprojekte/bedienhilfen.html

http://www.hmi.iao.fraunhofer.de