Siemens’ Data Base Enhances Machine Performance Across Industries

From trains to turbines, a vast range of machines generate and transmit data every second. With a view to providing benefits for its customers, Siemens wants to extract even more valuable information from this data.

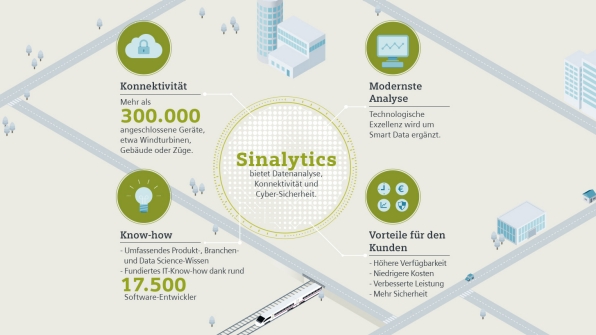

That’s why the company is consolidating these activities under the name Siemens Digital Services and has created an associated technology base called Sinalytics. It brings together all of the technological components needed for data integration and analysis, connectivity, and cyber security.

Sinalytics can securely connect to installed Siemens systems worldwide so that they can be remotely monitored and serviced. Cutting-edge analytical methods help Siemens experts predict and prevent faults, recognize opportunities for improving performance, and save energy and costs.

Finally, the analysis of huge and complex amounts of data enables the company to increase the availability and performance of its customers’ facilities and optimize maintenance intervals.

Sinalytics represents a big step on Siemens’ path to becoming a digital company. This combined with Siemens’ understanding of its customers’ needs and processes, enables even greater opportunities to optimize benefits for customers. In fiscal 2015, Siemens earned around €16 billion from its service business, with digital services accounting for €600 million of this amount.

How Predictive Maintenance Keeps Trains on Track

For the past decade, Siemens has been a pioneer in remote maintenance – with altogether more than 300,000 connected devices in almost all business areas, from traffic light controls to locomotives, CT scanners and gas and wind turbines. The major example is the Siemens’ Common Remote Service Platform (CRSP), which has now been integrated into the Sinalytics platform. One CRSP-example is is the remote maintenance of gas turbines.

This service tracks a turbine’s performance so precisely that it enables repairs to be initiated before a fault actually arises. Another service is Tubeguard, which was introduced in 2008. Tubeguard can reliably predict the end of an X-ray tube’s service life so that breakdowns can be prevented, thus making computer tomographs more economical.

Today, Sinalytics processes 17 terabytes of data per month. By way of comparison, in 2012 the platform processed three terabytes of data from 120,000 devices. Given this huge increase in data – and thus in actionable knowledge – with the new Sinalytics platform, predictive maintenanceis becoming even more important. Sinalytics’ refined analysis tools help customers reduce unscheduled downtimes and increase operating efficiency.

One of these customers is the Spanish railway company Renfe, which operates 26 Siemens Velaro E high-speed trains between Madrid and Barcelona as well as between Madrid and Malaga. Some 160 service employees work around the clock to maximize the availability of Renfe’s trains, a task for which they also use data analyses. As result of predictive maintenance, the punctuality rate of the Siemens trains has risen to as high as 99.9 percent. This high rate of availability enables Renfe to offer its customers a unique “money-back guarantee” that reimburses passengers for the entire ticket price if a train is late by 15 or more minutes.

Customers in Control

But digital services aren’t everything. Without the kind of deep understanding of products and processes that characterizes Siemens’ approach, a purely IT-based focus on service would not be able to generate the added value provided by Sinalytics. Whereas competitors focus on collecting as much information as possible at a central location, Siemens lets its customers decide where and how they want their data to be utilized.

Distributed analytics, which involves the pre-processing and analysis of data directly in local devices, will grow in importance. In the future, devices will make decisions on their own. “Customers want this, because their data often contains trade secrets,” says Matthias Goldstein, head of Siemens Corporate Technology’s Digitization Office.

Distributed analytics is also interesting for developments such as “Industrie 4.0”, where cyber physical systems produce individualized goods and independently reorganize themselves if a machine breaks down. Here, Sinalytics is closely networked with the Web of Systems, which is Siemens’ concept for the Internet of Things.

A few years from now, billions of devices will be connected to the Internet. Through the Web of Systems, Siemens is creating the basis for ensuring data security and making all of these devices reliable, secure, and durable.

A System that Spurs Innovation

One of Sinalytics’ key achievements is that it sets the stage for technological innovation. For example, instead of ordering a spare part from a warehouse, Sinalytics could, if a fault were imminent, send an order to a 3D printer located in the vicinity of a service technician or even directly to a customer location. But in order to open the door to this kind of flexibility, Siemens will have to be infused with digital expertise. Only then will it be able to exploit such potential in cooperation with its customers and extract maximum value added. “Sinalytics will help us overcome the challenges of the digital transformation for the benefit of our customers and ourselves,” concludes Goldstein.

Bernd Müller

Redaktion

Sebastian Webel

Dr. Norbert Aschenbrenner

Dr. Johannes von Karczewski

Kontakt für Journalisten

Florian Martini

Tel.: +49 (89) 636-33446