New EU Energy Label for Heating Systems and Storage Devices

The EU plans to introduce one energy label for components and systems.

http://eur-lex.europa.eu, ©European Union, 1998–2015

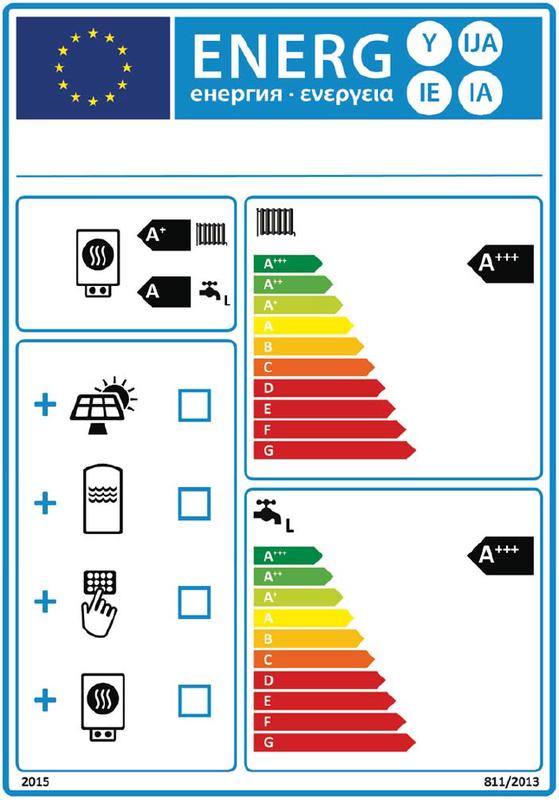

As of September 26, 2015, heating systems will have to bear an European Union energy label. The label, which already applies to refrigerators and washing machines, will now also be compulsory for heat pumps and heating systems with solar components.

Before a product’s efficiency class can be determined, however, specific technical information is required. Although testing methods and guidelines for classifying appliances already exist, they do not apply to the entire spectrum of heating systems.

This is because, in future, it is not only standard components that will be tested and compared, but also complex systems. Such testing methods can be implemented at the TestLab Solar Thermal Systems run by the Fraunhofer Institute for Solar Energy Systems ISE. The laboratory also works within committees to create relevant standards for implementing the energy label in future.

The TestLab Solar Thermal Systems (http://www.ise.fraunhofer.de/en/service-units/testlab-solar-thermal-systems) at Fraunhofer ISE tests solar thermal components and complete systems, as well as collectors and solar thermal storage systems. In its laboratory for systems and storage devices, Fraunhofer ISE establishes the characteristics required by industry partners to classify storage systems in compliance with the soon-to-be effective EU energy label.

The energy efficiency label determines the efficiency rating of energy-related products (ErP) in Europe. Its implementation represents a huge challenge for the heating and solar thermal industry. In response, experts at Fraunhofer ISE have created the infrastructure needed to take relevant and reliable measurements, as not all manufacturers have the capacities to do this themselves.

“It is particularly important to think about how such market-changing regulations will affect the technological development of the products they target right from the start, as they often run the risk of putting innovative technical solutions on hold. Generally speaking, however, the energy label is above all a great opportunity for the heating industry,” says Dr. Korbinian Kramer, head of the TestLab Solar Thermal Systems.

In addition to providing technical support, the test lab works within relevant committees to close gaps in evaluation methods and comparability and to replace interim procedures for awarding energy labels (known as EU transitional documents) with standardized norms as soon as possible. “Our energy label services are attractive to manufacturers for many reasons – not only can they reduce their company’s expenditure on carrying out similar tests in-house, but they can also benefit from our network and reputation as a neutral research institution,” says Dr. Kramer.

Fraunhofer ISE has years of experience in qualifying solar thermal components and systems, as well as numerous contacts in the industry. The team of experienced test engineers and scientists has already measured and characterized well over 500 collectors and systems. Further to its testing services, the test lab also helps customers to optimize their products through research and development.

Meet our experts at the ISH in Frankfurt from the 10th -14th March 2015 in Hall 10.3, Booth C79!

http://www.ise.fraunhofer.de/en/service-units/testlab-solar-thermal-systems – Website TestLab Solar Thermal Systems

http://www.ise.fraunhofer.de/en – Website Fraunhofer ISE