Industrial product and component labeling for extreme process conditions

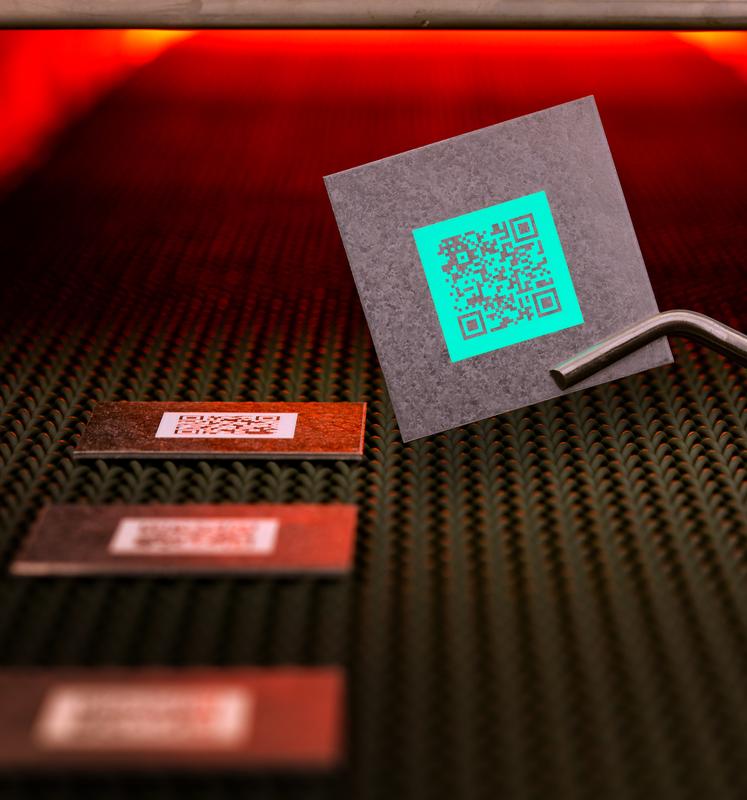

CeraCode<sup>®</sup> by Fraunhofer IKTS – high-temperature product labeling of a component under UV light.

Fraunhofer IKTS

Many raw materials and semi-finished products are exposed to extreme conditions in manufacturing processes or in application, for example high temperatures in metal processing or the glass and ceramics production.

In other areas, such as the leather industry or cleaning processes in the food and pharmaceutical branch, aggressive chemicals are used. Even climate and environmental influences place special demands on the surface of workpieces.

Such extreme conditions can hinder or even render the use of an individual component labeling based on barcodes or matrix codes over the entire process chain impossible. The reasons for this are varied, for example an insufficient thermal and chemical resistance of the codes, a lack of contrast and readability or corrosion during the application of the labeling.

To meet these challenges, researchers at Fraunhofer IKTS developed the CeraCode® technology. It is based on ceramic luminescent materials for inkjet printing. These materials display a pronounced luminescence in response to optical excitation, for example by UV radiation.

For an individual labeling, a special ink with luminescent materials is being printed onto the component. Implemented as barcode or data matrix code, the labeling provides a high contrast to the subsurface, regardless of ambient conditions. The ink shows excellent adhesion to various materials and is highly resilient both thermally and chemically.

“The applicability and robustness of CeraCode® has already been successfully demonstrated in the laboratory and at first pilot customer facilities. The focus of current IKTS research is on the integration of the labeling solution into existing processes. We succeeded in printing series components in the shortest possible time of less than 100 ms“, explains Dr. Thomas Härtling, scientist at Fraunhofer IKTS.

Today, the institute is able to offer a complete solution, ranging from the development of process-suitable ceramic inkjet inks to the generation and printing of the necessary codes and the adjustment of appropriate readers.

From April 25–29, 2016, IKTS researchers answer your questions in Hall 6 at Booth B16.

http://www.ikts.fraunhofer.de/en/pressandmedia/pressemitteilungen/industrial_mar…