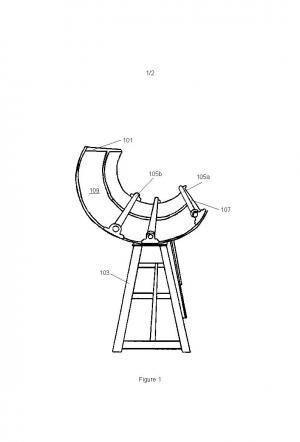

Apparatus to ease the unrolling of fibre sheets from the roll. Image copyright:Loo Huck Soo UiTM, Malaysia

The conventional preparation of fibre sheets from fibre rolls has been a problem in many factories in Malaysia, as workers manually unroll the fibre rolls and perform the cutting task on the floor leading to Work-related Musculoskeletal Disorders (WMSDs) such as low back pain and leg pain.

Other Occupational Health and Safety (OHS) problems such as tiredness and dizziness (as a result of constant squatting and back bending), sore throat, nose irritation and eye itchiness (due to fibre dust spreading around) are among the major complaints.

A new low cost apparatus was built to enable a worker to roll out fibre sheet from a fibre roll onto a table, as such, all cutting tasks can be conducted ergonomically at a comfortable working height with reduced dust contaminating the work environment. The apparatus can also reduce the inhalation of hazardous dust or fine particles by collecting them from the rolled material.

The embodiment of the invention comprises a frame which is a semi-circular construct supported on legs. There are three parallel rollers extended axially to the construct, two to support the rolled material while one to ease the rolling function at the dispensing end of the construct. The rolled material can then be conveniently pulled (by the leading edge) to unleash its sheet without coming into contact with any sharp edges which pose potential risks of damaging the dispensed length of the material.

The surface of the dispensed material is therefore substantially protected from any scratches, tear or any other forms of damage. The rollers are mounted on roller bearings on both sides of the construct where vertical rings are in place. The bearings allow forward and backward rotation of rollers with ease. The spacing between the support rollers is subtly arranged to ensure that the rolled material is well supported even if it reduces in size gradually after each round of dispensing action.

The two vertical rings specifically installed beside both sides of the construct are to retain the fibre roll within the central position. A dust collector having a configuration conforming to the semi-circular construct is located below the rollers to collect dust being shed from the rolled material and prevent it from falling out of the construct uncontrollably causing airborne dust transmission. Dust can thus be swept and collected from either end of the dust collector.

The rolled material which can be coreless, such as a fibreglass insulation blanket, a mineral wool roll, a natural fibre roll, a synthetic fibre roll or a plastic fibre roll. Alternatively, cored rolled material (with a centre-core) which can be a tissue roll, a kitchen towel roll, rolled foam material or rolled plastic bags, all of which can be unrolled and dispensed without the need of an axle.

An ergonomics study was conducted in a workplace where the cutting of glass fibre was carried out on the floor. The new invention was deployed to dispense glass fibre sheet from its roll to a matching work table, where the cutting task was carried out comfortably on table top. After 3 months of intervention, a tremendous reduction of workers' complaints and a significant productivity increase of 312% were recorded. A statistical paired-samples t-test confirmed the effectiveness of the new invention.

Intellectual Property Right: YES

Collaboration which could lead to the commercialization of this product is welcomed.

For further information contact:

Assoc Prof. IR. DR. LOO HUCK SOO

FACULTY OF MECHANICAL ENGINEERING

UNIVERSITY TEKNOLOGI MARA

MALAYSIA

drloohs@gmail.com

This invention won a GOLD medal at the invention innovation and design exposition 2014 (iidex2014) organized by Universiti Teknology MARA, Malaysia.