Shop-floor monitoring goes high tech

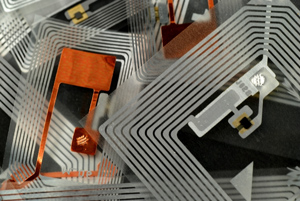

Radio-frequency identification tags in combination with a sophisticated computer program are used to provide a snapshot of shop-floor conditions in manufacturing industries. © Albert Lozano/Hemera/Thinkstock

Individual operations on the shop floor of an industrial plant can be tracked using a sophisticated automated monitoring system that employs advanced mathematical techniques. To track work in progress, A*STAR scientists combined the popular radio-frequency identification (RFID) tags with rigorous computational processing of ‘discrete-event observers’1. This system will enable managers to make better, more timely decisions.

“The factory of the future will have zero defects, zero waste and zero accidents,” explains Jinwen Hu, who developed the system with colleagues from the A*STAR Singapore Institute of Manufacturing Technology. To eliminate the trifecta of defects, waste and accidents, monitoring systems need to extract timely, precise and, most importantly, usable information.

To design such a monitoring system, Hu and co-workers, through consultation with manufacturers, identified specific areas of concern as being machine breakdown, staff availability, machine status and work order flow.

Getting data from machinery was relatively simple — RFID tags are ubiquitous, being used in everything from shoplifting prevention technology to electronic road-toll collection. However, it was not so easy to figure out how to best use the collected data. “The biggest challenge was designing an efficient scheme that allowed computers to rapidly process the data and engineers to conveniently modify the monitoring rules,” notes Hu.

Accordingly, Hu and colleagues incorporated a discrete-event observer in their program. This observer constructs complex events — such as delays in delivery — by using probabilities derived from past plant operations to extrapolate ‘simple event’ raw data collected by scanning RFID tags.

In testing the system on the shop floor of a precision machining plant, a simple event occurred when a worker received a work order and scanned the associated RFID. Once the worker had completed the task, the order was passed to another operator and the RFID was rescanned. This process was repeated until the order had been completed.

A simple event can be in one of two states — incomplete or complete. By combining several simple events and extrapolating based on the probabilities of simple events transitioning from incomplete to complete, the discrete-event observer can assess whether delayed delivery is likely. Managers can then use this information to take appropriate action to ensure timely delivery.

Hu notes that there is a lot of scope for improving the system. For instance, integrating more data analysis functions into the system will provide shop-floor managers with more effective advice. The team also intends to customize the monitoring system to other manufacturing industries.

The A*STAR-affiliated researchers contributing to this research are from the Singapore Institute of Manufacturing Technology. More information about the group’s research can be found at the SIMTech Manufacturing Execution and Control Group webpage.

Reference

Hu, J., Lewis, F. L., Gan, O. P., Phua, G. H. & Aw, L. L. Discrete-event shop-floor monitoring system in RFID-enabled manufacturing. IEEE Transactions on Industrial Electronics 61, 7083–7091 (2014). | article

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…