Open Assembly Platform Transforms Optical System Assembly

The flexible and easily programmable assembly platform, tailored to the needs of micro-optical assembly processes.

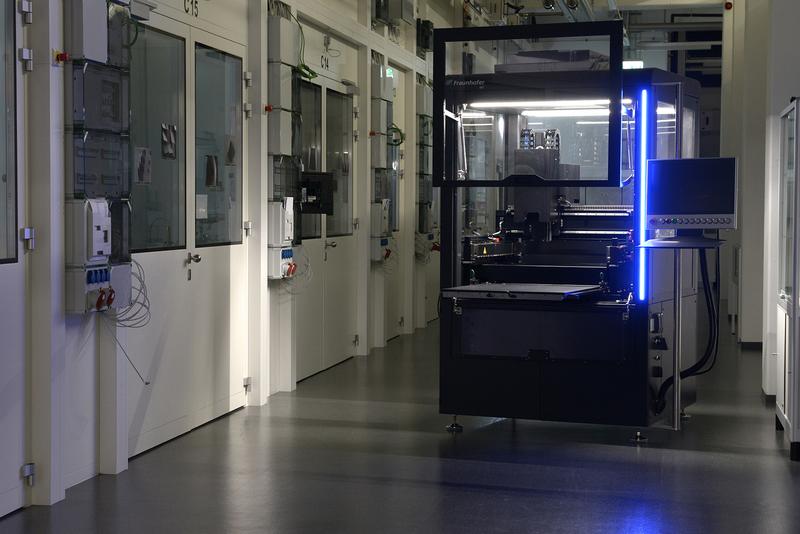

Source: Fraunhofer IPT

The new equipment, developed by the Fraunhofer IPT, operates with the highest level of precision and is suitable for a diverse range of optics assembly tasks – not only for active alignment of optical components, but also for inspecting or arranging micro-components. The alignment unit in the system has six degrees of freedom at its disposal and is used in conjunction with a portal system. This provides a working space of up to 500 x 500 mm² for optics assembly.

Since the system can be controlled in virtually any programming language, it can be integrated swiftly and flexibly within a range of production environments. The technical configuration of the system can be selected individually and optional extras include feed modules or transfer systems for example.

The system can also execute specified standard processes such as side tab and bottom tab assembly in order to produce large volumes fully or partially automatically. Basic functionalities such as part tracking and evaluation of the overall system effectiveness or process capability are supplied. The micro-manipulator can additionally be hand-operated for quick prototyping tasks should the effort involved in programming and setting up for automation be deemed not to be worthwhile.

The diverse range of programming options including LabVIEW, Python C# and SPS ensures that the system can be extended via the open platform and the software concept. As a result, users can develop and manage assembly programs themselves, without having to disclose sensitive know-how to third parties.

The kinematic configuration of the manipulator comprises a parallel structure and is based completely on flexure bearings. This permits even the smallest steps to be transferred without any loss to the end effector and avoids the occurrence of undesirable effects such as reverse play or hysteresis. The actuators used are piezo stepper motors, which combine an extremely high motion resolution of only a few nanometers with relatively large travel ranges. The end result is that highest levels of precision can be achieved along with the smallest of steps in any degree of freedom.

The new platform is a Fraunhofer in-house development and has been commercially available through the spin-off company Aixemtec since 2016. Novel assembly processes are initially being developed on a prototypical level at the Fraunhofer IPT. After successful demonstration, they can be used immediately for small- and mid-sized contract assembly operations through Aixemtec.

Simultaneously, the actual system is being set up for the customer under industrial standards once economically reasonable for the customer. Ideally, the assembly process is being tuned and qualified during the setup of the machine while Aixemtec is assembling first products in contract manufacturing. Customer benefits are manifold – amongst others, a short time-to-market, contract assembly in times of peak production, as well as receiving an assembly platform with a well-established and qualified process are most valued by customers today. This cooperation allows for Fraunhofer IPTs customers’ optimal exploitation of production-technological research results.

Several companies involved in assembling optical systems profit particularly readily from the innovative systems engineering and Fraunhofer IPTs and Aixemtecs close cooperation. The assembly of collimation optics for diode lasers or VCSEL, of solid state lasers with planar assembly systems, endoscope lenses or projectors for structured light are among the first examples of applications.

Scientists from the Fraunhofer IPT will also be presenting their latest research results in the field of optics in three talks to be given at “SPIE Photonics West”.

We hope to welcome you in Room 130 at the following times:

Tuesday 31.01.2017, 11.20

Individualized FAC on bottom tab subassemblies to minimize adhesive gap between emitter and optics

Sebastian Sauer

Tuesday 31.01.2017, 17.10

Robust adhesive precision bonding of laser optics II

Tobias Müller

Thursday, 02.02.2017, 11.10

Active Alignment of DOE based structured light application in consumer electronics

Daniel Zontar

Contact

Dipl.-Ing. Tobias Müller

Fraunhofer Institute for Production Technology IPT

Steinbachstraße 17

52074 Aachen

Germany

Phone +49 241 8904-493

tobias.mueller@ipt.fraunhofer.de

www.ipt.fraunhofer.de

This press release and a printable photo are also available under

www.ipt.fraunhofer.de/en/Press/Pressreleases/20170123_open-flexible-assembly-platform-for-optical-systems.html

http://www.ipt.fraunhofer.de/en/Press/Pressreleases/20170123_open-flexible-assem…

![[Figure 1] Schematic of next-generation CNT-PANI composite fiber supercapacitor and comparison graph with recent results](https://www.innovations-report.com/wp-content/uploads/2025/05/KIST_leads_next-generation_energy_storage_technolo_1746783279-e1746784635527-362x245.jpg)