Micromachining: Inclinations sounded out

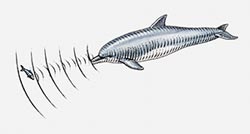

Echolocation is a powerful technique that uses sound or ultrasound waves to locate objects and surfaces. Ships and submarines, for example, use it to avoid collisions, and dolphins and microbats use it to locate prey.

Hongbin Yu and co-workers from the A*STAR Institute of Microelectronics, Singapore, have now used echolocation to measure the inclination of millimeter-sized ultrasonic sensors. In this new setting, their technique should extend the capabilities of devices that already use ultrasonic components, whether for locating defects in materials, visualizing anatomical structures or determining range.

Yu and his co-workers built on the success that so-called ‘capacitive micromachined ultrasonic transducers’ (CMUTs) have achieved over the past decade in generating and detecting ultrasound signals. These devices are fabricated using silicon micromachining technology, so the components are very compact and can be conveniently integrated with standard electronics components, which are also based on silicon.

“Our main goal was to explore a new application of the CMUT device,” says Yu. Consequently, the researchers harnessed these ultrasonic components for measuring tilt angles. They used three micromachined CMUTs — two senders and a common receiver — each measuring less than a tenth of a millimeter across. To test this array, they immersed it in a bath filled with oil. As they tilted the device, the oil surface stayed level — in the same manner that the water surface in a tilted glass would remain horizontal. However, the distances between the surface and the sensors at the bottom changed such that one sensor became closer to the surface than the other.

By measuring how long it took the ultrasound waves to travel from each of the senders to the receiver, via the oil surface where the waves were reflected, Yu and his co-workers could accurately determine the distances between the sensors and the surface. They could then calculate the tilt angle that the CMUT array had relative to the oil surface.

As many devices already contain ultrasonic components, the new sensor should be useful in a number of applications, according to Yu. “As one example, in an automotive robotic arm equipped with ultrasound transducers for fault detection, a tilt-sensing function should help improve the arm-control accuracy without greatly increasing the complexity of the device,” he explains.

Other areas where tilt-angle measurements are important include level determination for instrumentation and motion-state monitoring. With the team’s innovation, such functionality may now be added to ultrasonic medical-imaging and non-destructive materials-testing devices.

The A*STAR-affiliated researchers contributing to this research are from the Institute of Microelectronics

Journal information

Yu, H., Guo, B., Haridas, K., Lin, T.-H., Cheong, J. H. et al. Capacitive micromachined ultrasonic transducer based tilt sensing. Applied Physics Letters 101, 153502 (2012).

![[Figure 1] Schematic of next-generation CNT-PANI composite fiber supercapacitor and comparison graph with recent results](https://www.innovations-report.com/wp-content/uploads/2025/05/KIST_leads_next-generation_energy_storage_technolo_1746783279-e1746784635527-362x245.jpg)