Sustainable Manufacturing: New Methodology for Designers

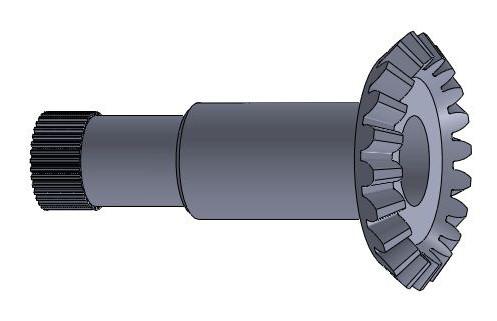

This bevel gear component is made of solid steel, one approach to producing the part.

(Graphic courtesy of Oregon State University)

The work was recently published in the Journal of Cleaner Production. It outlines a way to help designers and manufacturing engineers carefully consider all the ramifications of their design decisions, and to evaluate the possible different ways that a product could be built – before it ever hits the assembly line.

“There's a lot of demand by consumers, workers and companies who want to make progress on the sustainability of products and manufacturing processes,” said Karl Haapala, an associate professor in the OSU College of Engineering.

“There's usually more than one way to build a part or product,” he said. “With careful analysis we can identify ways to determine which approach may have the least environmental impact, lowest cost, least waste, or other advantages that make it preferable to a different approach.”

This movement, researchers say, evolved more than 20 years ago from an international discussion at the United Nations Conference on Environment and Development, which raised concerns about the growing scarcity of water, depletion of non-renewable sources of energy, human health problems in the workplace, and other issues that can be linked to unsustainable production patterns in industry.

The challenge, experts say, is how to consider the well-being of employees, customers, and the community, all while producing a quality product and staying economically competitive. It isn't easy, and comprehensive models that assess all aspects of sustainability are almost nonexistent.

“With current tools you can analyze various aspects of an operation one at a time, like the advantages of different materials, transportation modes, energy used, or other factors,” Haapala said. “It's much more difficult to consider all of them simultaneously and come out with a reasonable conclusion about which approach is best.”

To aid that effort, OSU researchers created a new methodology that incorporates unit process modeling and an existing technique called life-cycle inventory. This allowed them to quantify a selected set of sustainability metrics, and ask real-world questions. Should the product use a different material? Would running the production line faster be worth the extra energy used or impact on worker health and safety? Which approach might lead to injuries and more lost work? How can scrap and waste be minimized? Which design alternative will generate the least greenhouse gas emissions?

To illustrate this approach in the study, the researchers used three hypothetical “bevel gear” alternatives, a common part produced in the aircraft and automotive industry. Their six-step system considered energy consumption, water use, effluent discharge, occupational health and safety, operating cost, and other factors to evaluate the use of different materials and manufacturing processes – and ultimately concluded through mathematical modeling which of three possible designs was the most sustainable.

“When you make decisions about what is best, you may make value judgements about what aspect of sustainability is most important to you,” Haapala said. “But the modeling results have the potential to assist designers in performing those evaluations and in understanding the tradeoffs alongside other aspects of the manufacturing process.”

This work was supported by the Boeing Company and the Oregon Metals Initiative.

This assessment approach, when further researched and tested, should be applicable to a wide range of products during the design decision-making process, researchers said in the study.

![[Figure 1] Schematic of next-generation CNT-PANI composite fiber supercapacitor and comparison graph with recent results](https://www.innovations-report.com/wp-content/uploads/2025/05/KIST_leads_next-generation_energy_storage_technolo_1746783279-e1746784635527-362x245.jpg)