Learning to be precise

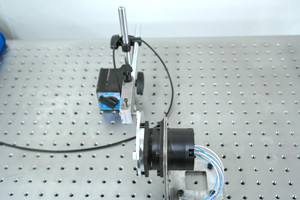

A capacitance gauge (top left) measures the accuracy of a micromanipulator system (bottom right), which is controlled by an enhanced analytic forward model. © 2014 A*STAR Institute for Infocomm Research

A mathematical model can improve the accuracy and repeatability of a positioning system by learning to anticipate tiny errors in its movements, show A*STAR researchers.

Micromanipulation systems are used to control objects’ positions with exquisite precision and play a vital role in applications such as telescopes and laser communication. Most rely on feedback sensors to reach the desired position, but these sensors introduce a time lag that can reduce the accuracy in applications requiring rapid responses. Although analytic forward models (AFMs) can be used to predict when positioning errors might occur and compensate for them in advance, they must be extremely accurate and uniquely tailored to a particular micromanipulation system.

Now, Yan Wu of the A*STAR Institute for Infocomm Research in Singapore, in collaboration with colleagues from the Harbin Institute of Technology in China, has developed a system that combines both approaches. The team created a machine learning algorithm that can improve the accuracy of its analytic control model based on sensor feedback [1].

Their enhanced analytic forward model (EAFM) combines a simple AFM with a ‘heteroscedastic Gaussian process (HGP) algorithm, which compensates for any residual difference between the AFM’s output and the desired position.

The team built a tip–tilt micromanipulation system that uses four piezoelectric drivers to change the position of its platform. These drivers can move the platform up to 32 micrometers, and position it with an accuracy of 10 nanometers. A capacitance gauge located next to the platform can measure its position to within one nanometer (see image).

The researchers trained the HGP algorithm by running 125 random control signals through their micromanipulation system. It learned to make probabilistic predications that could compensate for errors in the AFM’s output.

The team then tested the system with 30 different control signals, which were intended to move the platform by up to 28 micrometers. In every case, the EAFM system achieved smaller positioning errors than the AFM alone. And in trials of continuous movement, where the platform had to hit a series of four different points over a brief time, the EAFM outperformed the AFM in all but one of ten tests.

“All the experiments demonstrated that the AFM has errors with a very large variance (between 1 and 8 micrometers), whereas the EAFM keeps the errors at around 1 micrometer or less,” says Wu. “We are now putting this micromanipulator platform into a laser communication system, while investigating methods to further reduce the steady-state errors.”

The A*STAR-affiliated researchers contributing to this research are from the Institute for Infocomm Research

Reference:

[1] Su, Y., Dong, W., Wu, Y., Du, Z. & Demiris, Y. Increasing the accuracy and the repeatability of position control for micromanipulations using heteroscedastic Gaussian processes. 2014 IEEE International Conference on Robotics and Automation (ICRA), 4692–4698 (2014).

Associated links

A*STAR article

Media Contact

More Information:

http://www.researchsea.comAll latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

“Nanostitches” enable lighter and tougher composite materials

In research that may lead to next-generation airplanes and spacecraft, MIT engineers used carbon nanotubes to prevent cracking in multilayered composites. To save on fuel and reduce aircraft emissions, engineers…

Trash to treasure

Researchers turn metal waste into catalyst for hydrogen. Scientists have found a way to transform metal waste into a highly efficient catalyst to make hydrogen from water, a discovery that…

Real-time detection of infectious disease viruses

… by searching for molecular fingerprinting. A research team consisting of Professor Kyoung-Duck Park and Taeyoung Moon and Huitae Joo, PhD candidates, from the Department of Physics at Pohang University…