Glass-on-glass lamination for large-area OLEDs right from the roll

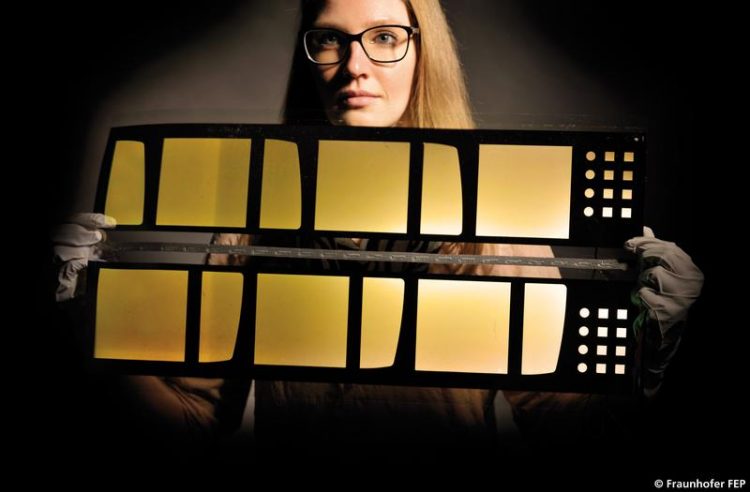

Glass-on-glass laminated OLED made using the Fraunhofer FEP roll-to-roll OLED process line © Fraunhofer FEP

Organic light-emitting diodes have already found acceptance as a light source in first luminaires on the market on rigid glass. However, far larger shares of the market could be acquired, if flexible large-area OLEDs could be manufactured cost-effectively with consistent quality.

Scientists are working feverishly on this worldwide. Large-area OLEDs could be employed not only in innovative furniture designs, but also deliver good service in other sectors requiring specialized curved design, such as architectural lighting and automotive, for example.

The organic layers of the OLED are sensitive to oxygen and moisture and needs to be well protected. Flexible ultra-thin glass meets the stringent requirements of a hermetic barrier, free of defects and pinhole freedom for large OLED emissive surfaces.

Fraunhofer FEP has had success not only in applying OLEDs to flexible ultra-thin glass, but also in encapsulating the devices using an additional thin glass layer in a single roll-to-roll manufacturing step. A high-performance adhesive was applied over the entire surface of the encapsulating glass in advance in collaboration with tesa SE.

This adhesive glass film is subsequently laminated to the OLED-coated ultra-thin glass. Fraunhofer FEP will be presenting this type of OLED at AIMCAL 2016, in this case based on G-Leaf™ ultra-thin glass by Nippon Electric Glass Co Ltd. (NEG). A 10 cm × 25 cm emissive surfaces will be on display.

“But encapsulation is not the only challenge for flexible large area OLEDs that need to remain stable over long periods. In order to get them to emit, a highly conductive, transparent oxide layer with good light coupling properties is required and reliable electrical contacts to the emitting layers with low contact resistance is essential,” explains Dr. Stefan Mogck, Head of Roll-to-Roll Organic Technology at Fraunhofer FEP. “We are proud of having optimized our process, and that these layers can be applied very homogenously to the flexible glass.”

Making dependable electrical connections to the ultra-thin glass without damaging it was especially challenging. The scientists will be working with customers in the future on non-destructive techniques of integration.

Fraunhofer FEP offers its industrial partners process and product development over the complete value chain customized to their requirements. Processes for treatment and coating flexible glass for customer-specific emissive surfaces in different sizes and colors can be developed, and even flexible OLED prototypes fabricated at customers’ requests. In addition, the Institute can develop matching driver circuitry for supplying power to the prototypes.

Fraunhofer FEP at AIMCAL 2016

Talks

Monday, May 30

Session: Coating and Laminating Short Course

13:30 – 17:00, Location: Bellevue I

Oliver Miesbauer, Fraunhofer IVV / Dr. rer. nat. John Fahlteich, Fraunhofer FEP

Tuesday, May 31

Track: Web Coating and Web Handling,

Session: Web Surface / Barrier

14:30 – 15:00, Location: Bellevue I

Surface modification of polyethylene terephthalate (PET) and oxide coated PET for adhesion improvement

Juliane Fichtner, Fraunhofer FEP

Track: Vacuum

Session: Sputtering, Coating Equipment, Inline control

16:00 – 16:30, Location: Bellevue II

Adapted particle bombardment during layer growth by pulse magnetron sputtering

Dr. rer. nat. Daniel Glöß, Fraunhofer FEP

Wednesday, June 1

Track: Vacuum

Session: Pretreatment, Substrate Film, Simulation

10:30 – 11:00, Location: Bellevue II

Vacuum plasma treatment and coating of fluoropolymer webs – challenges and applications

M.Eng. Cindy Steiner, Fraunhofer FEP

Thursday, June 2

Track: Vacuum

Session: New Applications, Emerging Technologies, Capacitors, Photovoltaic

8:30 – 9:00, Location: Bellevue II

New vacuum coating technologies for metal strips and foils

Prof. Dr. rer. nat. Christoph Metzner, Fraunhofer FEP

10:30 – 11:00, Location: Bellevue II

Present status of Roll-to-Roll Fabrication for OLED lighting

Michael Stanel, Fraunhofer FEP

Labtour

Fraunhofer FEP

June 1, 2016

Fraunhofer FEP invites you to an exciting tour to our labs: applied R&D for the industry at its best. During the tour, we will present pilot scale experimental coating equipment, e.g. MAXI (in-line vacuum coating for metal strips and sheets), coFlex® 600 (roll-to-roll pilot sputter roll coater), novoFlex® 600 (roll-to-roll pilot coater), atmoFlex (non-vacuum roll to roll coating and electron beam surface treatment) and a roll-to-roll process line for the deposition of OLED.

Press contact:

Annett Arnold

Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP | Phone +49 351 2586 452 | Annett.Arnold@fep.fraunhofer.de

Winterbergstraße 28 | 01277 Dresden | Germany | www.fep.fraunhofer.de

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…