Engineers Create Tiny Robots That Mimic Insect Movement

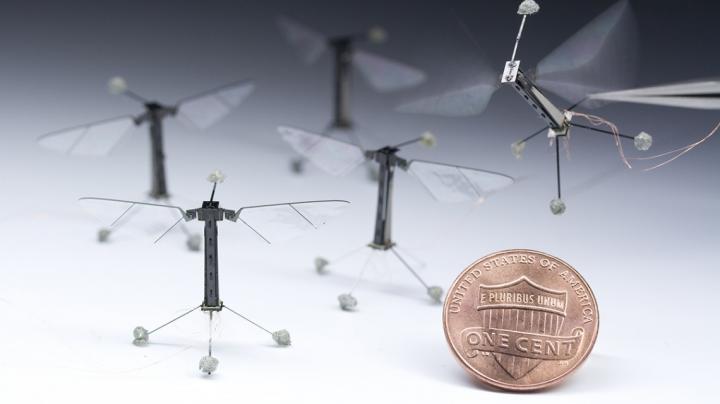

RoboBees manufactured by the Harvard Microrobotics Lab have a 3 centimeter wingspan and weigh only 80 milligrams. Cornell engineers are developing new programming that will make them more autonomous and adaptable to complex environments.

Credit: Harvard Microrobotics Lab

The amount of computer processing power needed for a robot to sense a gust of wind, using tiny hair-like metal probes imbedded on its wings, adjust its flight accordingly, and plan its path as it attempts to land on a swaying flower would require it to carry a desktop-size computer on its back.

Silvia Ferrari, professor of mechanical and aerospace engineering and director of the Laboratory for Intelligent Systems and Controls, sees the emergence of neuromorphic computer chips as a way to shrink a robot's payload.

Unlike traditional chips that process combinations of 0s and 1s as binary code, neuromorphic chips process spikes of electrical current that fire in complex combinations, similar to how neurons fire inside a brain.

Ferrari's lab is developing a new class of “event-based” sensing and control algorithms that mimic neural activity and can be implemented on neuromorphic chips. Because the chips require significantly less power than traditional processors, they allow engineers to pack more computation into the same payload.

Ferrari's lab has teamed up with the Harvard Microrobotics Laboratory, which has developed an 80-milligram flying RoboBee outfitted with a number of vision, optical flow and motion sensors. While the robot currently remains tethered to a power source, Harvard researchers are working on eliminating the restraint with the development of new power sources. The Cornell algorithms will help make RoboBee more autonomous and adaptable to complex environments without significantly increasing its weight.

“Getting hit by a wind gust or a swinging door would cause these small robots to lose control. We're developing sensors and algorithms to allow RoboBee to avoid the crash, or if crashing, survive and still fly,” said Ferrari. “You can't really rely on prior modeling of the robot to do this, so we want to develop learning controllers that can adapt to any situation.”

To speed development of the event-based algorithms, a virtual simulator was created by Taylor Clawson, a doctoral student in Ferrari's lab. The physics-based simulator models the RoboBee and the instantaneous aerodynamic forces it faces during each wing stroke. As a result, the model can accurately predict RoboBee's motions during flights through complex environments.

“The simulation is used both in testing the algorithms and in designing them,” said Clawson, who has successfully developed an autonomous flight controller for the robot using biologically inspired programming that functions as a neural network. “This network is capable of learning in real time to account for irregularities in the robot introduced during manufacturing, which make the robot significantly more challenging to control.”

Aside from greater autonomy and resiliency, Ferrari said her lab plans to help outfit RoboBee with new micro devices such as a camera, expanded antennae for tactile feedback, contact sensors on the robot's feet and airflow sensors that look like tiny hairs.

“We're using RoboBee as a benchmark robot because it's so challenging, but we think other robots that are already untethered would greatly benefit from this development because they have the same issues in terms of power,” said Ferrari.

One robot that is already benefiting is the Harvard Ambulatory Microrobot, a four-legged machine just 17 millimeters long and weighing less than 3 grams. It can scamper at a speed of .44 meters-per-second, but Ferrari's lab is developing event-based algorithms that will help complement the robot's speed with agility.

###

Ferrari is continuing the work using a four-year, $1 million grant from the Office of Naval Research. She's also collaborating with leading research groups from a number of universities fabricating neuromorphic chips and sensors.

![[Figure 1] Schematic of next-generation CNT-PANI composite fiber supercapacitor and comparison graph with recent results](https://www.innovations-report.com/wp-content/uploads/2025/05/KIST_leads_next-generation_energy_storage_technolo_1746783279-e1746784635527-362x245.jpg)