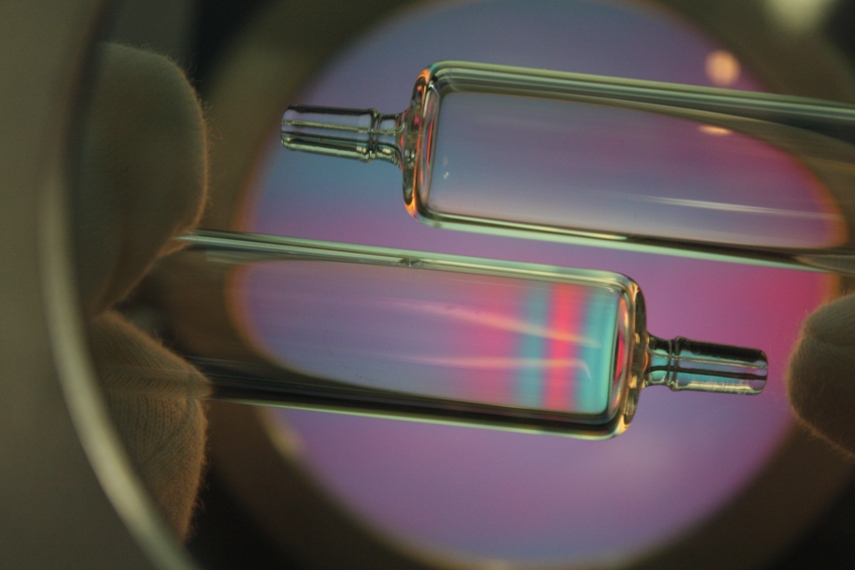

Tempering Glass: Enhancing Pharmaceutical Bottle Production

The glass is formed under heat, which means there are residual thermal stresses and the glass is more likely to crack. For this reason, these thermal stresses must be removed before they are put into use. Stress relief is achieved by tempering.

Innovative MAX infrared ovens from Heraeus Noblelight support this process with convincing results.

Are you interested in the entire case story about glass tempering with the new MAX infrared oven?

Contact us here!

Industrial infrared heating oven

The MAX ovens combine infrared radiation with convection and optimal reflection. Only quartz glass materials including QRC® nano-reflectors are used inside the oven.

From simulation to solution

The oven size can be adjusted to the product and the process. Numerical simulation in the design phase makes the heat process especially energy-efficient. To achieve a maximum product temperature of 900°C, a MAX oven needs less than ten minutes, and it can cool down in less than ten minutes as well. This enables rapid product changes. The MAX oven can be used for both batch and continuous operation.

MAX oven – especially energy-efficient

Tests show that in an oven with a heated length of 700 mm and a chamber cross-section of 150 x 150 mm the maximal emitter temperature is achieved within less than one minute. In continuous operation at 900°C holding temperature, the necessary holding power is just about 3 kW, due to the excellent energy efficiency.

- High purity for sensitive products

- Thermal shock resistance for fast processes

- Best optical properties

- Excellent mechanical stability even at very high temperatures

- Very good processability for flexible oven dimensions

- Very good homogeneity of the temperature field due to diffuse reflection

Heraeus Noblelight GmbH

Heraeussstr. 12-14

D-63450 Hanau

Phone +49 6181 35 8547

Fax +49 6181 35 16 8547

E-Mail: hng-info@heraeus.com

![[Figure 1] Schematic of next-generation CNT-PANI composite fiber supercapacitor and comparison graph with recent results](https://www.innovations-report.com/wp-content/uploads/2025/05/KIST_leads_next-generation_energy_storage_technolo_1746783279-e1746784635527-362x245.jpg)