Catalyst for Green Biodiesel Production from Unrefined Feedstock

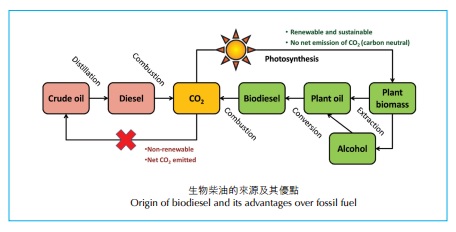

Origin of biodiesel and its advantages over fossil fuel

Copyright : Hong Kong PolyU

Biodiesel is a sustainable liquid fuel originated from biomass. However, traditional liquid biodiesel catalyst generates a huge amount of waste water in the final purification procedure.

A new class of solid catalyst is developed by precise surface chemistry engineering to catalyze the biodiesel production. With excellent adaptability to low grade unrefined feedstock like waste cooking oil, the catalyst can provide complete solution to the waste water problem.

In addition, it operates at a significant lower temperature and pressure as compared with the existing solid biodiesel catalyst due to its high catalytic activity, which can reduce the energy and cost required for biodiesel production.

Special Features and Advantages:

• One-step biodiesel production from low grade unrefined feedstock

• No washing with fresh water required for biodiesel produced

• Operates at low temperature and pressure which can reduce the cost

• The catalyst demonstrates excellent reusability and robustness

Applications:

This new catalyst is designed for one-step energy saving biodiesel synthesis from low grade unrefined feedstock containing high free fatty acid and water content with no post-production washing required. Toxic methanol used can also be replaced by ethanol or propanol which makes the process more sustainable.

Awards:

• Gold Medal – 43rd International Exhibition of Inventions of Geneva, Switzerland (April 2015)

• Thailand Award for Best International Invention from The National Research Council of Thailand – 43rd International Exhibition of Inventions of Geneva, Switzerland (April 2015)

For further information contact:

Principal Investigator

Dr Ka-fu YUNG

Department of Applied Biology & Chemical Technology

Institute for Entrepreneurship

Tel: (852) 3400 2929

Fax: (852) 2333 2410

Email: pdadmin@polyu.edu.hk

Associated links

Hong Kong PolyU article

![[Figure 1] Schematic of next-generation CNT-PANI composite fiber supercapacitor and comparison graph with recent results](https://www.innovations-report.com/wp-content/uploads/2025/05/KIST_leads_next-generation_energy_storage_technolo_1746783279-e1746784635527-362x245.jpg)