Plug-In Hybrids: Cost-Efficiency Calculated 1,000x Faster

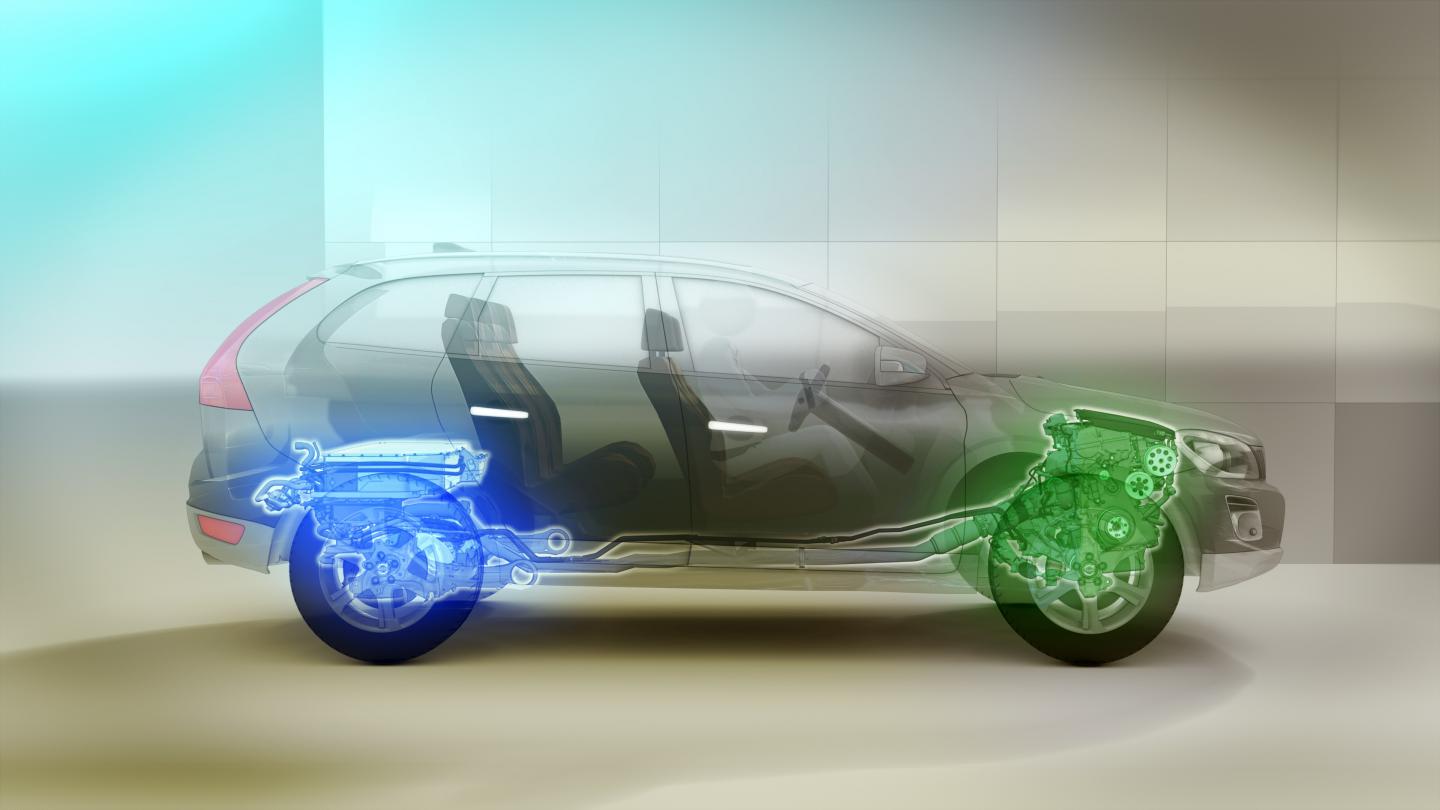

The new method can be used to calculate the cost-efficiency of plug-in hybrids such as Volvo XC60 Plug-in Hybrid Concept.

Credit: Volvo Car Group

Plug-in hybrids are more fuel efficient thanks to the combination of electric motor and battery. However, the higher number of components the higher the manufacturing costs.

The fuel savings must be calculated based on very long driving cycles, as variations in the way the car is driven and charged on different days plays a major role in fuel consumption. Analysing the fuel efficiency of different plug-in hybrids over long cycles is extremely time-consuming. A whole month of driving has to be analysed second by second, and millions of variables calculated.

Now a research team at Chalmers University of Technology has developed a quick and simple method for engineers to calculate the lowest cost, factoring in both manufacture and driving behaviour. Researcher Mitra Pourabdollah describes the method in her doctoral thesis:

“The operating cost of a plug-in hybrid depends on many different variables, such as the way you drive, how you charge the battery and how far you drive between charges,” she says. “Driving habits also affect what size battery you need. Component prices, different battery types and different driving habits combined result in a huge number of parameters that impact the overall cost.”

The new solution that Mitra Pourabdollah presents involves using a so-called convex optimisation algorithm. The algorithm acts as a tool in which researchers enter the various parameters that can affect the cost of a plug-in hybrid, and see the results very quickly. The new method speeds up this part of the design process twentyfold. In extreme cases, calculations that would normally take a thousand hours can be completed in half an hour – almost two thousand times faster than previously.

“Dramatic time savings at this stage will allow more opportunities to consider other aspects of the design of the drivetrain and gain a broader perspective,” Mitra Pourabdollah claims.

“Rapid feedback is essential for creative work,” says Anders Grauers, one of the supervisors of the project. “Even discounting such extreme cases, the new method means that you can get the results of your calculations the same working day, a very significant benefit for the creative process.”

Mitra Pourabdollah's research colleagues Nikolce Murgovski and Lars Johannesson Mårdh originally came up with the idea of applying convex optimisation to a complex vehicle model. They began by developing a method for plug-in hybrid buses. Following on from their work, Mitra Pourabdollah studied how the method could be applied to passenger cars. The basic algorithm is very flexible – and fun to work with.

“Finding a way to describe the various components that fit convex optimisation is a bit like a game,” explains Mitra Pourabdollah. “The method has many other application areas as well, for example in active safety”.