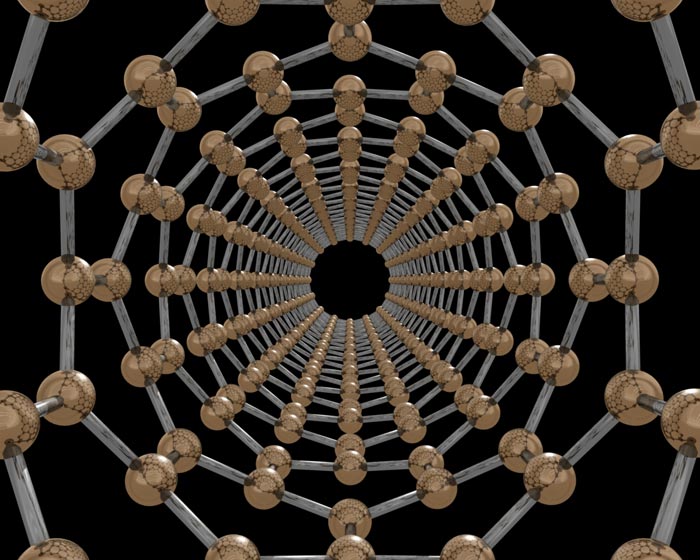

Conceptual diagram of carbon nanotubes

Copyright : Nanotubes 005/mirdc/CC (http://mirdc.deviantart.com/art/Nanotubes-005-62393002)

Ever since their discovery, carbon nanotubes (CNTs) have been considered the ultimate additive to improve the mechanical properties of structural ceramics, such as aluminum oxide, silicon nitride and zirconium dioxide.

Yet despite the remarkable strength and stiffness of CNTs, many studies have reported only marginal improvements or even the degradation of mechanical properties after these super-materials were added. Indeed, the ability of CNTs to directly reinforce a ceramic material has been strongly questioned and debated in the last ten years.

So what’s going on? In a review paper published in the journal Science and Technology of Advanced Materials, researchers at the National Institute for Materials Science in Japan explore what is preventing the reinforcing ability of CNTs from being exploited in a ceramic matrix.

The researchers list three fundamental questions, which must be addressed in order to examine and understand the direct reinforcing ability and mechanism of CNTs in a ceramic matrix:

1. Does the intrinsic load-bearing ability of CNTs change when embedded in a ceramic host matrix?

2. When there is an intimate atomic-level interface without any chemical reaction with the matrix, could one expect any load transfer to the CNTs?

3. Can CNTs – which are nanoscale and flexible – improve the mechanical properties of the matrix at the macroscale when individually, intimately and uniformly dispersed? If so, how?

The authors briefly review recent studies addressing the above questions. In particular, they discuss a recently discovered reinforcing mechanism at the nanoscale, which is responsible for unprecedented, simultaneous mechanical improvements including strengthening, toughening and softening of the ceramic host matrix. They also highlight a new processing method that enables the fabrication of defect-free CNT-concentrated ceramics and CNT-graded composites with unprecedented properties, for applications ranging from biomedical implants and tissue engineering to thermoelectric power generation.

For further information contact:

Dr Mehdi Estili

International Center for Young Scientists

National Institute for Materials Science

1-2-1 Sengen, Tsukuba 305-0047, Japan

E-mail: ESTILI.Mehdi@nims.go.jp

Dr Yoshio Sakka

Advanced Ceramics Group, Materials Processing Unit

National Institute for Materials Science,

1-2-1 Sengen, Tsukuba 305-0047, Japan

E-mail: SAKKA.Yoshio@nims.go.jp

More information about the research paper

Sci. Technol. Adv. Mater. 15 (2014) 064902

doi:10.1088/1468-6996/15/6/064902

Journal Information

Science and Technology of Advanced Materials (STAM) is the leading open access, international journal for outstanding research articles across all aspects of materials science. Our audience is the international materials community across the disciplines of materials science, physics, chemistry, biology as well as engineering.

The journal covers a broad spectrum of materials science research including functional materials, synthesis and processing, theoretical analyses, characterization and properties of materials. Emphasis is placed on the interdisciplinary nature of materials science and issues at the forefront of the field, such as energy and environmental issues, as well as medical and bioengineering applications

http://iopscience.iop.org/1468-6996

For more information about the journal Science and Technology of Advanced Materials, please contact

Mikiko Tanifuji

Publishing Director

Science and Technology of Advanced Materials

Email: TANIFUJI.Mikiko@nims.go.jp

Associated links

Link to research paper

Journal information

Sci. Technol. Adv. Mater. 15 (2014) 064902

doi:10.1088/1468-6996/15/6/064902