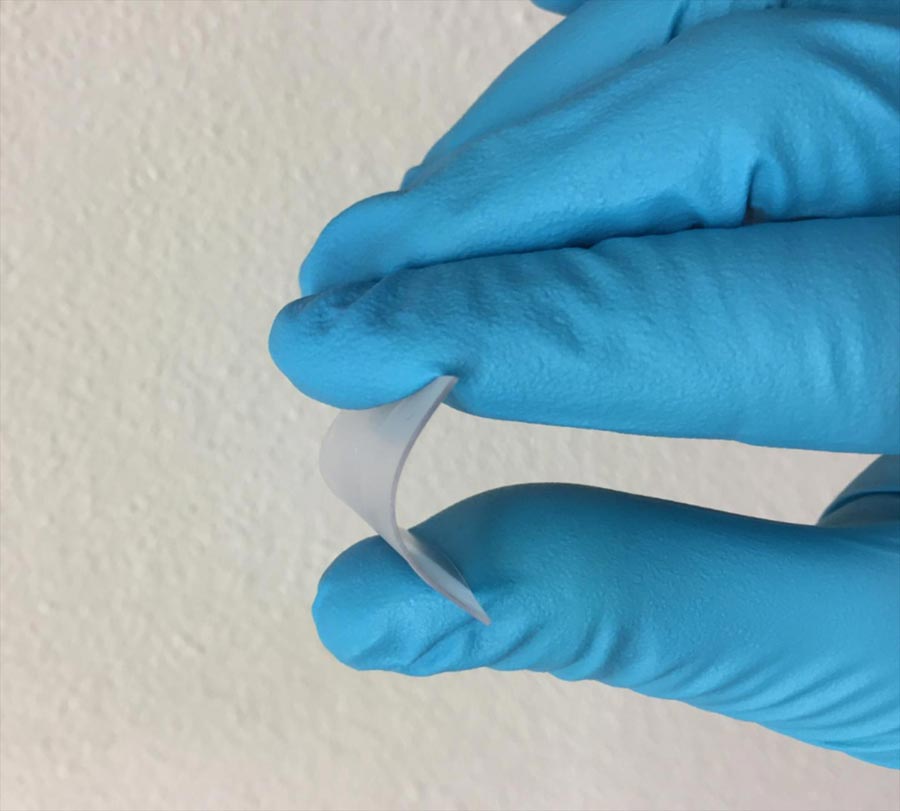

Here's what the anti-icing coating looks like when it is attached to a flexible piece of plastic. The coating itself is just 30 microns thick, or about the half the width of an average human hair.

Credit: NTNU Nanomechanical Lab

Scientists and engineers have been waging a quiet but determined battle against an unlikely problem: the build-up of ice on different structures.

A thin coating of ice on solar panels can wreak havoc with their ability to generate electricity. Thin layers of ice on the vanes of wind turbines can slow their efficiency.

And a thin layer of ice on an electrical transmission line can be the first step in dangerous ice build up. That's exactly what happened in Quebec in 1998, when an accumulation of ice on transmission lines and towers crushed more than 150 towers, leaving more than a million people in Quebec and Ontario without power and causing roughly CDN $5 billion in damage.

Now, a research team at the Norwegian University of Science and Technology (NTNU) is working with a novel approach to prevent ice build-up– by cracking it.

“We think we have found a very interesting method to reduce ice adhesion which is unique, and a breakthrough in the anti-icing community,” says Zhiliang Zhang, a professor in the Department of Structural Engineering at NTNU and head of the SLICE research project team that discovered the technique.

Their approach has just been published in Soft Matter, a publication of the Royal Society of Chemistry.

Conventional de-icing not an option

If you've ever taken a flight in the cold of winter, you've almost certainly experienced one approach to keeping ice from sticking to a surface, which involves spraying de-icing fluid on a plane's wings and other critical parts of the aircraft.

The spray physically removes any accumulated ice, but it also makes the surface of the plane less likely to accumulate snow or ice (although only for a brief period).

In most industrial applications, however, such as on an offshore rig or ship in the Arctic, or on wind turbines in places where cold winters can lead to icing, spraying antifreeze on a structure that you want to protect from ice build-up isn't an option.

Living with ice, not preventing it

Scientists and engineers have thus created substances that are called superhydrophobic. This means they excel at repelling water. Since you need water to make ice, the approach should prevent ice formation.

Superhydrophobic substances can be sprayed onto surfaces, or objects can be dipped into the substance. Often they are made of fluorinated chemicals, which are not particularly environmentally friendly. And, Zhang says, scientists are not completely certain that a superhydrophobic surface is also one that can remain ice-free, at least for long periods.

That fact motivated Zhang and his colleagues at the NTNU Nanomechanical Lab to try a completely different approach.

“Our strategy is to live with ice,” he said, by letting it form but by ensuring that the layers of ice crack away from the surface and fall off.

Nano-, micro- and macro-scale cracking

In their efforts to find ways to keep ice from sticking to surfaces, ice researchers have tried manipulating physical forces to generate interface cracks at the nanoscale, which is at the atomic scale, and the micro scale.

Many ice researchers have tried creating slippery surfaces, which rely on surface chemistry to cause cracks by weakening the atomic bonds between the ice and surface. These surface-chemistry-related substances have been called NACI, for nano-crack initiators.

At the microscale, ice researchers have built microbumps into the surface they want to protect from ice. These microbumps are called micro-crack initiators, or MICI, because their roughness promotes microcracks at the contact between the surface and the ice, and limits the ability of the ice to stick to the treated surface.

Even together, however, both of these mechanisms aren't perfect at preventing ice from sticking to a surface. Zhang and his colleagues tested a number of commercial and homemade coatings that rely on NACI and MICI to lower the ability of ice to stick to the surface.

They gradually realized that if they added another structure below the surface, they could then form large macro-cracks at the meeting between the surface and the ice, called the interface. They called this mechanism MACI, for macro-crack initiator.

As the cracks get larger, the ice is less and less likely to stay on the surface. In this way, MACI holds the key to getting rid of ice build-up on surfaces, Zhang said.

MACI: Surfaces with inner pillars and holes

To test their idea, Zhang and his colleagues created subsurface layers that had microholes or pillars. They then made a thin film of a substance called polydimethylsiloxane, or PDMS, which covered the holey, bumpy substructure layers.

They tested different design of their MACI inner structures. They also tested what would happen if they used multiple layers with inner holes. The researchers were surprised to find that surfaces that had the MACI substructures had ice adhesion strengths that were at least 50 per cent weaker than the pure PDMS surfaces without MACI. A surface with the special MACI design gave the researchers the results they were hoping for, with some of the lowest values for ice adhesion, or stickiness, ever measured.

“The ice adhesion strength for common outdoor steel or aluminum surfaces is around 600-1000 kPa,” Zhang said. “By introducing the novel MACI concept to the surface design, we reached the super-low ice adhesion value of 5.7 kPa.”

Cracking the code to cracking ice

Zhang and his colleagues have more work to do as they develop their idea, but they are excited that they may have cracked the code to preventing dangerous ice buildup while limiting unwanted environmental effects.

“Traditional active de-icing techniques… can have major detrimental effects on structures and the environment,” Zhang said. “But passive super-low ice adhesion surfaces avoid all those detrimental effects. This is very interesting not only for the scientific community, and for Arctic applications, but for solar panels, for shipping and transmission lines. There are a lot of applications related to everyday life.”

Zhang and his team are now working to establish an NTNU Anti-icing Lab, which would have state-of-the-art facilities to study the initiation of ice formation, called ice nucleation, and the different properties of surfaces when it comes to ice adhesion, or stickiness.

As planned (and if funded), the lab will support fundamental anti-icing research and provide a testing service and material selection guidance for Norwegian industry.

The research has been partly financed by Statoil and the Research Council of Norway via the FRINATEK project SLICE.

###

Reference: Multiscale crack initiator promoted super-low ice adhesion surfaces. Zhiwei He, Senbo Xiao, Huajian Gao, Jianying He and Zhiliang Zhang. Soft Matter, 2017, Advance Article. DOI: 10.1039/c7sm01511a