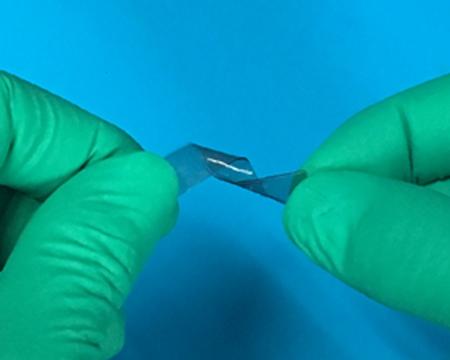

Silk could soon be used to produce more sensitive and flexible body sensors like this one.

Credit: Yingying Zhang

The researchers are presenting their work today at the 254th National Meeting & Exposition of the American Chemical Society (ACS). ACS, the world's largest scientific society, is holding the meeting here through Thursday. It features nearly 9,400 presentations on a wide range of science topics.

“There is a whole world of possibilities for silk sensors at the moment. Silk is the ideal material for fabricating sensors that are worn on the body,” Yingying Zhang, Ph.D., says. “One possibility we foresee is for them to be used as an integrated wireless system that would allow doctors to more easily monitor patients remotely so that they can respond to their medical needs more rapidly than ever before.”

Body sensors, which are usually made with semiconductors, have shown great potential for monitoring human health. But they have limitations. For instance, strain sensors, which measure changes in force, cannot be highly sensitive and highly stretchable at the same time. Silk, a natural material that is stronger than steel and more flexible than nylon, could overcome these problems. The fiber is also lightweight and biocompatible. However, silk doesn't conduct electricity very well. To address this challenge, Zhang and colleagues at Tsinghua University in China sought to find a way to boost the conductivity of silk so it could be successfully used in body-sensing devices.

The researchers decided to try two different strategies. In one approach, they treated the silk in an inert gas environment with temperatures ranging from 1,112 degrees to 5,432 degrees Fahrenheit. As a result, the silk became infused with N-doped carbon with some graphitized particles, which is electrically conductive. Using this technique, the scientists have developed strain sensors, pressure sensors and a dual-mode sensor capable of measuring temperature and pressure simultaneously.

In the other approach, the team fed either graphene or carbon nanotubes to silkworms. Some of these nanoparticles were naturally incorporated into the silk produced by the worms. So far, this method hasn't produced electrically conductive fibers, but the researchers are still experimenting with this technique and are hopeful they can make it work.

Based on the preliminary results, Zhang wants to explore ways to create an integrated set of silk-based, self-sustaining sensors that would be powered by nano-generators. She also suggests that her team's silk sensors might be used to build more realistic robots that can sense touch, temperature or humidity and can even distinguish between different people's voices.

###

Zhang acknowledges funding from the National Natural Science Foundation of China and the Key Technologies Basic Research and Development Program.

The American Chemical Society, the world's largest scientific society, is a not-for-profit organization chartered by the U.S. Congress. ACS is a global leader in providing access to chemistry-related information and research through its multiple databases, peer-reviewed journals and scientific conferences. ACS does not conduct research, but publishes and publicizes peer-reviewed scientific studies. Its main offices are in Washington, D.C., and Columbus, Ohio.

To automatically receive press releases from the American Chemical Society, contact newsroom@acs.org.

Note to journalists: Please report that this research was presented at a meeting of the American Chemical Society.

Title

Processing of silkworm silk for applications in flexible electronics

Abstract

Silkworm silk, with five thousand years' usage history, is a popular natural material for clothes or wearing accessories. In this talk, I will present our work on exploring the application of silk in flexible electronics. The development of flexible electronics and equipment attracts significant interests in recent years. Low-dimensional carbon materials are one kind of ideal materials for flexible electronics. It is of great importance to explore low cost and scalable preparation approaches for high performance flexible carbon materials-based wearable electronics. We demonstrated that carbonized silk fabric with a plain-weave structure, based on its unique N-doped graphitic carbon nanostructure and the macroscale woven structure, could be worked as strain sensors with both of high sensitivity (gauge factor of 9.6 in the strain range of 0%-250% and 37.5 in the range of 250%-500%) and high tolerable strain (more than 500%). The as-obtained sensors have fast response (<30 ms) and high durability (>10,000 cycles). It was demonstrated that such strain sensors could be used for monitoring both of vigorous human motions (such as jumping, marching, jogging, bending and rotation of joints), subtle human motions (such as pulse, facial expression, respiration and phonation) and even sound, and further demonstrated the capture and reconstruction of human body movements with our sensors, showing their superior performance and tremendous potential applications in wearable electronics and intelligent robots. In addition, transparent electronics skins based on graphene, carbon nanotubes, and silk nanofibers will be demonstrated.

![[1] Key Research Findings on Transfer-Printed Alumina–Gold Dual-layer Protective Coating](https://www.innovations-report.com/wp-content/uploads/2025/07/Transfer_printing_technology_for_lithium_protectiv_1753252750-e1753252940671-362x245.jpg)