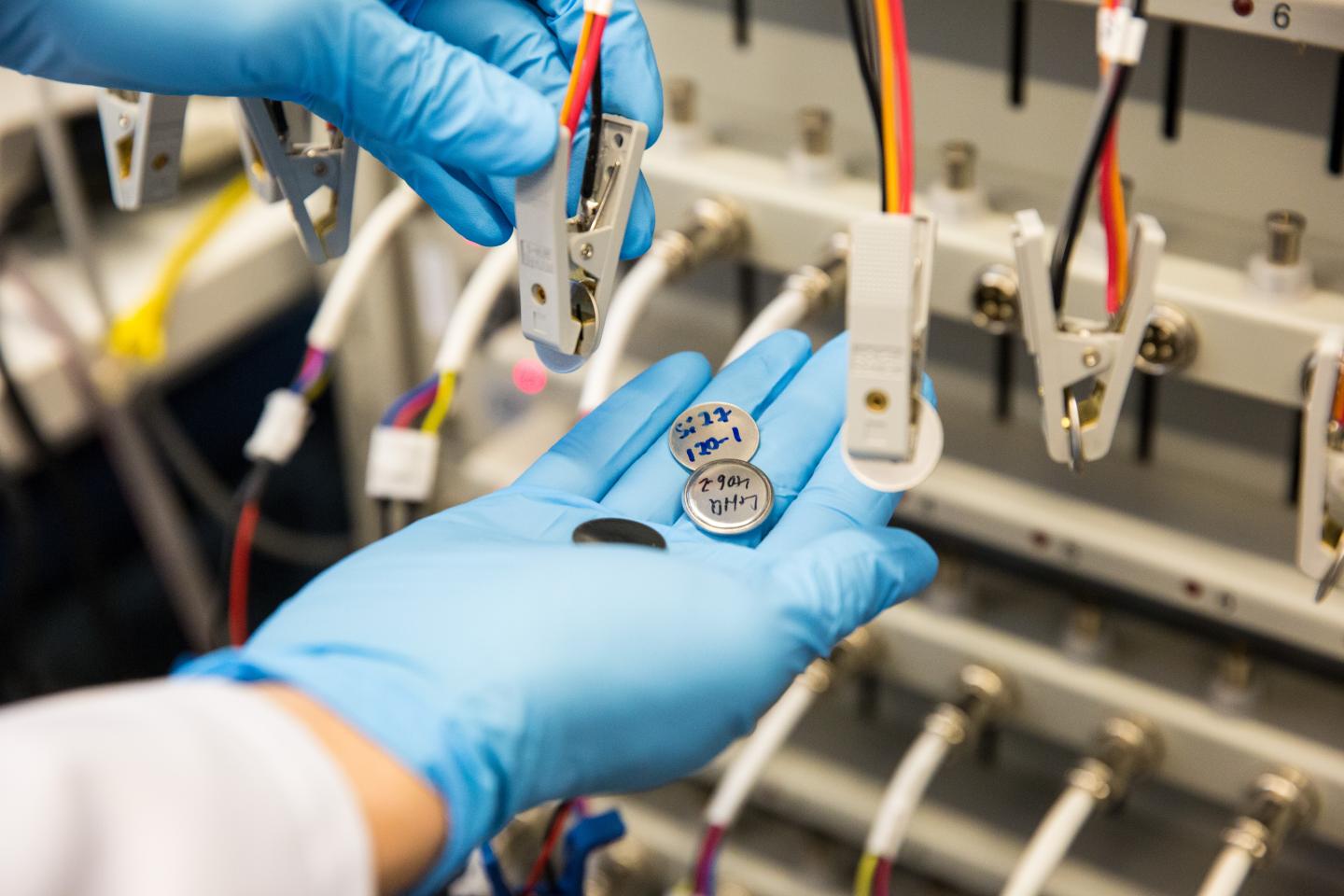

Researchers tested the material on coin cells.

Credit: Mikko Raskinen / Aalto University

Researchers used a combined atomic/molecular layer deposition (ALD/MLD) technique, to prepare lithium terephthalate, a recently found anode material for a lithium-ion battery.

When microbatteries are manufatured, the key challenge is to make them able to store large amounts of energy in a small space. One way to improve the energy density is to manufacure the batteries based on three-dimensional microstructured architectures. This may increase the effective surface inside a battery- even dozens of times. However, the production of materials fit for these has proven to be very difficult.

– ALD is a great method for making battery materials fit for 3D microstructured architectures. Our method shows it is possible to even produce organic electrode materials by using ALD, which increases the opportunities to manufacture efficient microbatteries, says doctoral candidate Mikko Nisula from Aalto University.

The researchers' deposition process for Li-terephthalate is shown to comply well with the basic principles of ALD-type growth, including the sequential self-saturated surface reactions, which is a necessity when aiming at micro-lithium-ion devices with three-dimensional architectures.

The as-deposited films are found to be crystalline across the deposition temperature range of 200?280 °C, which is a trait that is highly desired for an electrode material, but rather unusual for hybrid organic?inorganic thin films. An excellent rate capability is ascertained for the Li-terephthalate films, with no conductive additives required.

The electrode performance can be further enhanced by depositing a thin protective LiPON solid-state electrolyte layer on top of Li-terephthalate. This yields highly stable structures with a capacity retention of over 97% after 200 charge/discharge cycles at 3.2 C.

The study about the method has now been published in the latest edition of Nano Letters.

###

For more information:

Doctoral candidate Mikko Nisula, Aalto University mikko.nisula@aalto.fi

Professor Maarit Karppinen, School of Chemical Technology, Aalto University maarit.karppinen@aalto.fi, tel. +358 50 384 1726

Press photos: http://materialbank.

Captions:

3. Researchers tested material on coin cells. Photo: Mikko Raskinen / Aalto University

5. Sample makes a steel substrate look blue. Behind the hand there is a ALD reactor. Photo: Mikko Raskinen / Aalto University

6. Doctoral canditate Mikko Nisula holds in his hand a sample on a steel substrate. Behind the hand there is a ALD reactor. Photo: Mikko Raskinen / Aalto University

Tweet:

Smaller batteries for smaller devices: ALD/MLD used for organic lithium electrode thin films @aaltouniversity

Article:

Mikko Nisula and Maarit Karppinen: Atomic/Molecular Layer Deposition of Lithium Terephthalate Thin Films as High Rate Capability Li-Ion Battery Anodes. Nano Lett., 2016, 16 (2), pp 1276-1281. Link to the article: http://pubs.