Perfect Material for Air Filters Developed by Russian Physicists

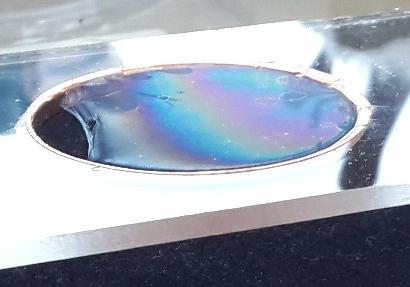

A sample of the new fabric in reflected light.

Credit: The picture is courtesy of the researchers

A research team from the Institute of Theoretical and Experimental Biophysics of the Russian Academy of Sciences have synthesized the material that is perfect for protection of respiratory organs, analytical research and other practical purposes.

An almost weightless fabric made of nylon nanofibers with a diameter less than 15 nm beats any other similar materials in terms of filtering and optical properties.

The scientists whose work is published in Macromolecular Nanotechnology Journal, characterize their material as lightweight (10-20 mg/m2), almost invisible (95% light transmission: more than that of a window glass), showing low resistance to airflow and efficient interception of <1 micrometer fine particulate matter.

The wording “nanofibers” in the researchers' article is more than a fashion statement. Previously, the same team demonstrated that reducing fiber diameter from 200 nanometers down to 20 decreased filter resistance to airflow by two thirds, and this effect could no longer be explained by classical aerodynamics.

When an obstacle size is smaller than the free path of gas molecules, the standard methods estimating aerodynamic resistance based on the continuum theory no longer work. In normal conditions, the mean free path of air molecules makes 65 nanometers.

The mean free path is the average distance one molecule manages to cover before colliding with another. Only if all obstacles are much bigger than this value, the free stream coming at them can be rightfully considered a continuous medium.

The scientists used the technique called electrospinning: a jet of a dissolved polymer is ejected through a special nozzle aiming at a target under action of an electric field. From the other side, ethanol is electrosprayed. The polymer jet and the alcohol ions take the opposite electric charges. Colliding in the air, they form ultra-thin fibrous films.

Electrospinning technology as a way to produce nonwoven fibrous filters has been developed back in the 50s to purify air in atomic industry. However, the researchers introduced an important improvement: instead of obtaining nanomats on a solid conducting substrate like before, now with the new technology, a free filter is formed covering a 55-mm hole in a non-conductive polycarbonate screen.

The published work completed the cycle of the authors' papers devoted to development of the manufacturing technology and studies of properties of nanofilters manufactured using this new process. It was established that the unique optical and filtering properties originate from a special mechanism of “healing” holes and defects in free standing filters. Such holes literally attract fibers landing onto the filter surface.

As a result, a good filter without big holes can be obtained from a minimum amount of nanofibers and, accordingly, with a minimum resistance to airflow. Moreover, active healing of big holes between threads provides the filters with the properties inherent in filters with calibrated pores, so called track-etched membranes (Nuclepores). The scientists have also demonstrated that the “healing” mechanism does not work in the conventional electrospinning technique where nanofibers are deposited onto a conducting substrate completely at random.

The testing of nylon-4,6 electrospun films showed that thess almost weightless and invisible fabrics trap no less than 98% of airborne dust particles. For testing, the scientists used particles from 0.2 to 0.3 micron in diameter. This roughly corresponds to the dust that is not caught by the nasal pharynx, and penetrates the lungs causing a number of dangerous medical conditions. Submicron particles (< 1 micrometer in diameter) are the ones also used to test industrial and medical filters. To assess performance, resistance to airflow is tested as well.

Experiments to measure resistance have been made on singular samples so far. In real filters a multi-layer surface with a complex configuration is normally used. The experiments showed that the nylon-4,6 filtering material had the best properties out of all types of fabric previously described . In terms of interception extent to filter weight ratio and interception-resistance to airflow ratio, the new filtering material beats any existing equivalents by several times.

At first it looks like a ring sitting on a sheet of paper. In reality, it is a sample of the new fabric for filters. The small red spot on top of “l” letter is a spot wherea laser beam penetrates the film. Low intensity of dispersed light demonstrates high transparency of the new material. A transmission index of the new product is higher than that of a good window glass. The picture is courtesy of the researchers.

Speaking about possible applications of this material, the scientists claim it is more than the obvious air and water purification from particulate matter. Since the material surpasses glass in transparency, it can be used in biological research. For example, after pumping air or water through the new filter intercepted microorganisms may be directly observed right on the transparent filter under a microscope. Again, this effect is due to ultra-fine threads. Their thickness is significantly less than even visible light wavelength.