New 'microcapsules' have potential to repair damage caused by osteoarthritis

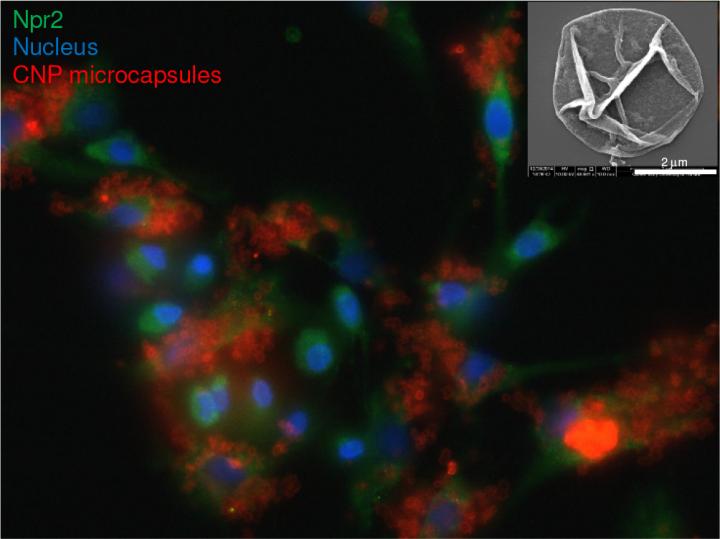

This is a picture of a CNP microcapsule. A new 'microcapsule' treatment delivery method developed by researchers at Queen Mary University of London (could reduce inflammation in cartilage affected by osteoarthritis and reverse damage to tissue.

Credit: QMUL

A protein molecule called C-type natriuretic peptide (CNP), which occurs naturally in the body, is known to reduce inflammation and aid in the repair of damaged tissue. However, CNP cannot be used to treat osteoarthritis in patients because it cannot target the damaged area even when the protein is injected into the cartilage tissue. This is because CNP is easily broken down and cannot reach the diseased site.

The researchers constructed tiny microcapsules, just 2 microns in diameter, with individual layers containing CNP that could release the protein slowly and therefore deliver the treatment in the most effective way.

In experiments on samples of cartilage taken from animals, they showed that the microcapsules could deliver the anti-inflammatory CNP in a highly effective way. The researchers believe that injections of microcapsules could in the future be used to heal damaged cartilage in people with osteoarthritis. The injections could be delivered easily by a GP.

Dr Tina Chowdhury from QMUL's School of Engineering and Materials Science, who leads the research, said:

“If this method can be transferred to patients it could drastically slow the progression of osteoarthritis and even begin to repair damaged tissue.

“CNP is currently available to treat other conditions such as skeletal diseases and cardiovascular repair. If we could design simple injections using the microcapsules, this means the technology has the potential to be an effective and relatively cheap treatment that could be delivered in the clinic or at home.”

Dr Stephen Simpson, Director of Research at Arthritis Research UK said:

“Current treatment options for osteoarthritis are limited, and therefore developing new ways to treat this painful and debilitating condition is currently a major area of research. The focus is not only about identifying promising new targets, as delivery of a drug to the appropriate site can often be as challenging as developing the treatment itself, and can hinder getting otherwise effective medicines to patients. This work represents a good example of how researchers are developing innovative new approaches to get around this problem.”