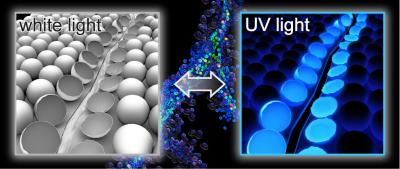

Colorless, non-fluorescent microcapsules use a type of fluorescence called aggregation-induced emission (AIE), which becomes brighter as the indicator solidifies from solution and is visible under ultraviolet (UV) light.

Credit: Autonomous Materials Systems Group, Beckman Institute for Advanced Science and Technology, University of Illinois

If you've never had the plumber to your house, you've been lucky. Pipes can burst due to a catastrophic event, like subzero temperatures, or time and use can take a toll, wearing away at the materials with small dings and dents that aren't evident until it's too late.

But what if there were a way to identify those small, often microscopic failures before you had to call for help?

The Autonomous Materials Systems (AMS) Group at the Beckman Institute for Advanced Science and Technology has recently found a new way to identify microscopic damage in polymers and composite materials before total failure occurs.

“Autonomous indication of small cracks has exciting potential to make structures safer and more reliable by giving time to intervene and repair or replace the damaged region prior to catastrophic failure,” said Nancy Sottos, professor of materials science and engineering, and one of the authors of “A Robust Damage-Reporting Strategy for Polymeric Materials Enabled by Aggression-Induced Emission,” recently published in ACS Central Science. The paper is part of a research project selected as a finalist for the Institution of Chemical Engineers (IChemE) Global Awards 2016.

The researchers sequestered fluids containing turn-on fluorescence indicators in microcapsules, and then incorporated them into polymeric materials.

“We've developed microcapsules that are colorless and non-fluorescent when intact,” said Maxwell Robb, Beckman Institute Postdoctoral Fellow and a lead author on the paper. “We can embed them into materials, and when damage occurs, the microcapsules will release their payload and become fluorescent, indicating that repair is needed.”

Previous work led by Wenle Li, a postdoctoral research associate and co-first author of the study, had investigated another type of indicator within microcapsules, which underwent a chemical reaction upon release to produce a color change. However, the nature of the chemical reaction limited the system to a narrow range of materials.

The new method uses a type of fluorescence called aggregation-induced emission (AIE), which becomes brighter as the indicator solidifies from solution and is visible under ultraviolet (UV) light. The unique mechanism of indication, which relies on a physical change of state instead of a chemical reaction, enables excellent performance in a wide variety of materials and for visualizing different types of damage.

“The elegance of this system lies in its versatility as well as its sensitivity,” said Li. “We can easily visualize a fluorescence signal resulting from mechanical damage as small as two microns.”

The research is funded by BP, which is interested in coating oil and gas pipelines with a polymer coating that will be able to indicate damage. The goal is to target damage at its earliest stage to prevent further deterioration, improve safety and reliability, and reduce life cycle costs associated with regular maintenance and inspection.

Using instruments in Beckman's Microscopy Suite, the group was able to study the microcapsules and coatings of various materials, image them, and correlate the fluorescence signals to 3D structures of the damaged coatings.

“This is incredibly interdisciplinary work,” said Robb. “Having knowledge about the aggregation-induced emission effect, and being able to design the chemistry of the microcapsule system was the starting point. Then there is the actual application of this technology into materials and coatings, which relies heavily on the expertise within materials science and engineering.”

The AMS Group includes Sottos, Jeffrey Moore, professor of chemistry, and Scott White, professor of aerospace engineering, who also co-authored the study. Their work has led to new discoveries in self-detecting and self-healing materials.

“To impact the coatings industry, materials with self-reporting capability must meet a few criteria: they must be simple, not change the way the materials are traditionally applied, and perform just as well,” said Moore. “Our approach hits this target – the new self-reporting function is realized by just one simple additive.”

The next steps for this research are to combine damage indication with self-healing materials.

“If you could couple this technology that lets you know that damage has occurred with a self-healing material that tells you when the damage has been healed, it could be really powerful,” said Robb.

“We have developed both turn-on fluorescence and color-changing indication systems. Our vision is to combine these multi-channel strategies to enable materials that monitor their mechanical integrity throughout the entire polymer lifecycle,” said Li.