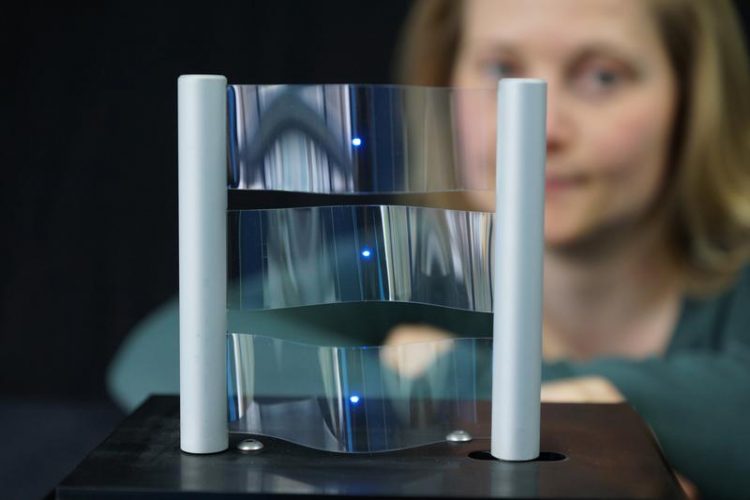

New conductive coatings for flexible touchscreens – presentation at nano tech 2015 in Japan

Transparent, conductive coatings Copyright: INM; only free within this press release

For the nanoparticle inks, the researchers are using what are known as TCOs, or transparent conducting oxides. “We use the TCOs to produce nanoparticles with special properties”, says Peter William de Oliveira, Head of the Optical Materials Program Division, “the TCO ink is then created by adding a solvent and a special binder to these TCO particles”.

The binder performs several tasks here: it not only makes the TCO nanoparticles adhere well on the film; it also increases the flexibility of the TCO coating: in this way, the conductivity is maintained even when the films are bent. The ink can then be applied to the film directly by gravure printing using a printing plate. After curing under UV light at 150°C, the coating is ready.

The transparent electronic inks allow conductor tracks to be produced unproblematically even on a large-scale by means of the classic reel-to-reel process. Initial trials at INM have been promising.

The researchers all agree that the use of structured rollers will in the future allow even large, structured conductive surfaces to be printed with a high throughput at low cost. Conductive coatings with TCOs are usually applied by means of high vacuum techniques. The method known as sputtering, however, is very expensive.

From January 28 to 30, the researchers of the INM will present this and further results at the German Pavilion, Booth 5J-21. At the German Pavilion, the Association of German Engineers (VDI) will concentrate the expertise of all German exhibitors at the nano tech.

The German Pavilion is supported by the Federal Ministry for Economic Affairs and Energy (BMWi). An oral presentation on „Materials and Processing for functionalized Surfaces“. will take place at the Main Theater, Hall 5, on January 29, German Day.

Your contact at the Booth:

Dr. Karsten Moh

Dr. Thomas Müller

Mareike Frensemeier

Your expert at the INM:

Dr. Peter William de Oliveira

INM – Leibniz Institute for New Materials

Head Optical Materials

Phone: +49681-9300-148

peter.oliveira@inm-gmbh.de

INM conducts research and development to create new materials – for today, tomorrow and beyond. Chemists, physicists, biologists, materials scientists and engineers team up to focus on these essential questions: Which material properties are new, how can they be investigated and how can they be tailored for industrial applications in the future? Four research thrusts determine the current developments at INM: New materials for energy application, new concepts for medical surfaces, new surface materials for tribological applications and nano safety and nano bio. Research at INM is performed in three fields: Nanocomposite Technology, Interface Materials, and Bio Interfaces.

INM – Leibniz Institute for New Materials, situated in Saarbruecken, is an internationally leading centre for materials research. It is an institute of the Leibniz Association and has about 195 employees.

http://www.inm-gmbh.de/en

http://www.nanotechexpo.jp/

http://www.nanotech-tokyo.german-pavilion.com/content/en/home/home.php

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…