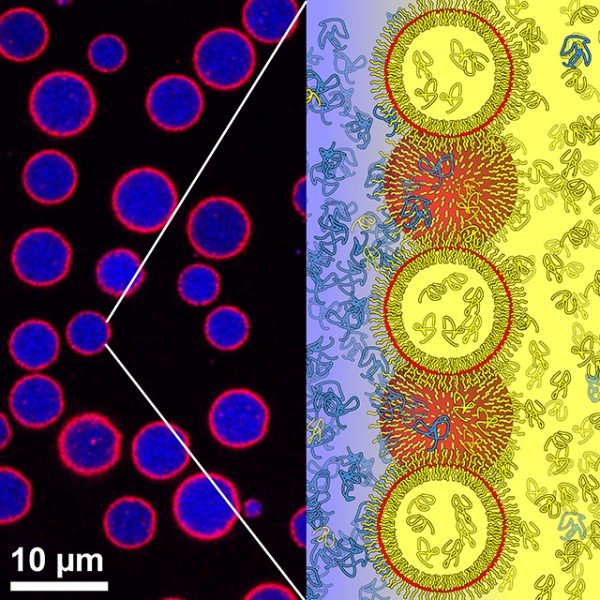

Image courtesy of Christine Keating

On the left: Fluorescent microscope image shows artificial bioreactors composed of sugar-based dextran polymer solution (blue) encapsulated within a shell of lipid vesicles (red). On the right: schematic illustration of what the vesicles look like at the aqueous/aqueous interface. Blue and yellow shading indicate the interior and exterior solutions.

Artificial cells that mimic their natural counterparts help scientists learn the secrets of complex processes, such as how plant cells turn sunlight, water, and carbon dioxide into fuel. Today’s artificial cells often become unstable when materials transit the membrane.

Scientists have developed a new artificial cell where lipid vesicles (small pools of fatty molecules) self-assemble around treated water droplets. The result is an artificial cell or microscopic bioreactor.

The Impact

This new type of cell-like bioreactor could offer substantial advantages for carrying out complex synthesis processes that mimic natural processes. It could also offer benefits in conducting massively parallel chemical reactions.

Summary

Scientists discovered a new process for spontaneously forming “artificial cells” that can function as bioreactors through the self-assembly of polymer-rich water droplets within lipid-rich water droplets.

In essence, the artificial bioreactor is composed of a shell membrane through which reactants and products can selectively pass through, and an interior environment where the reactions occur. Lipid-, polymer-, and gel-based processes for preparing bioreactors modelled after biological cells have been previously developed; maintaining stable reaction-relevant internal environments while simultaneously allowing reactants and products to easily pass through have remained a key challenge.

Now, researchers at the Pennsylvania State University have developed a new type of water-in-water composite emulsion, based on self-assembly of microscale aqueous droplets surrounded by nanoscale lipid capsules in a continuous aqueous phase. These lipid-stabilized water-in-water assemblies provide an exciting alternative to traditional giant lipid vesicles, or liposomes, as artificial cell mimics. In comparison to traditional giant liposomes, which encapsulate a similar aqueous volume within a single continuous lipid membrane, the structures introduced here offer

(1) facile encapsulation of proteins in the interior phase as well as polymer agents for controlling the progress of the desired reaction

(2) excellent uniformity in droplet size and contents

(3) much greater access into and out of the interior volume.

The researchers found that negatively charged lipid capsules, each on the order of 100 nanometers in diameter, self-assemble at the aqueous interface of polymer-rich droplets that are tens of microns in diameter. The repulsion between the lipid capsules due their negative charges forced them to maintain their assembled structure, essentially gluing them together and stabilizing the overall bioreactor composite. A particularly exciting capability of these composite assemblies is the preferential partitioning of DNA within the interior compartment based on the length of the DNA, which bodes well for designing and preparing micro-reactors in which combinations of reactants can be selectively introduced and maintained at desired levels. In addition, ribozyme-induced cleavage of RNA encapsulated within the interior is as another example of the bioreactor’s unique capability.

Funding

U.S. Department of Energy, Office of Science, Basic Energy Sciences (development and characterization of liposome-stabilized emulsions) and the NASA Exobiology program (RNA compartmentalization and cleavage reactions).

Publications

D.C. Dewey, C.A. Strulson, D.N. Cacace, P.C. Bevilacqua, and C.D. Keating, “Bioreactor droplets from liposome-stabilized all-aqueous emulsions.” Nature Communications 5, 4670 (2014). [DOI: 10.1038/ncomms5670]

Contact Information

Kristin Manke

kristin.manke@science.doe.gov