Nanowires highly 'anelastic,' research shows

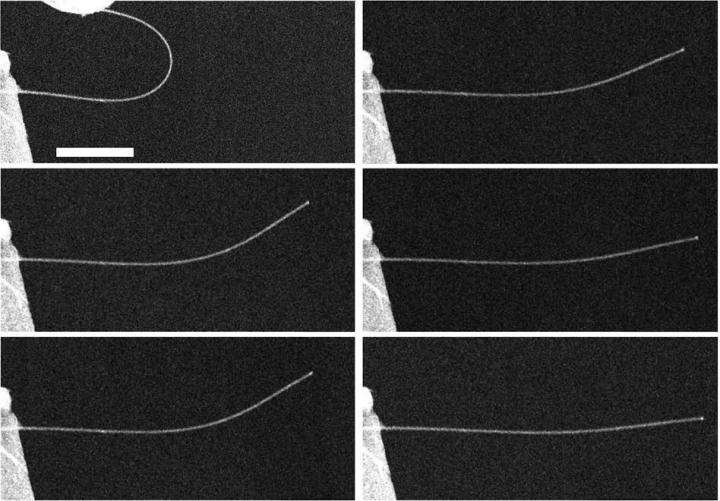

Zinc oxide nanowires return to shape slowly after being bent, new research from Brown and NC State shows. That property, called anelasticity, suggests that nanowires might be good in applications that require absorption of shocks or vibrations. Credit: Zhu lab / NC State

“What's surprising here is the magnitude of the effect,” said Huajian Gao, the Walter H. Annenberg Professor of Engineering and a coauthor of a new paper describing the research. “Anelasticity is present but negligible in many macroscale materials, but becomes prominent at the nanoscale. We show an anelastic effect in nanowires that is four orders of magnitude larger than what is observed in even the most anelastic bulk materials.”

The findings are significant in part because anelastic materials are good absorbers of kinetic energy. These results suggest that nanowires could be useful in damping shocks and vibrations in a wide variety of applications.

“During the last decade, zinc oxide nanowire has been recognized as one of the most important nanomaterials with a broad range of applications such as mechanical energy harvesting, solar cells, sensors and actuators,” Gao said. “Our discovery of giant anelasticity and high energy dissipation in zinc oxide nanowires adds a new dimension to their functionality.”

The experiments for the study were done in the lab of Yong Zhu, an associate professor of mechanical and aerospace engineering at NC State. Zhu and his colleagues used a delicate apparatus to bend nanowires under a scanning electron microscope.

The work showed that, after the bending strain was released, the wires returned to about 80 percent of their original shape quickly. But they recovered the rest of their original shape much more slowly, over the course of up to 20 or 30 minutes. That is a far more prominent anelastic effect than is common at the macroscale.

To understand why the effect is so prominent, Zhu and his team worked with Gao's lab at Brown, which specializes in theoretical modeling of nanoscale systems. The model that Gao and his colleagues developed suggests that the anelasticity is a result of impurities in the wires' crystal lattice.

Lattice impurities come in two forms. There are vacancies, where atoms are missing from the lattice; and there are interstitials, where the lattice has extra atoms. When a wire is bent to form an arch, there's higher compressive strain on the underside of the arch compared to the upper side. The compression pushes interstitial atoms toward the outside edge, and draws the vacancies toward the inside. When the strain is released, those impurities migrate back to where they started.

That migration takes a bit of time, which is why the wire returns to shape slowly. Because nanowires are so small, the impurities need only travel a short distance to generate a perceptible anelastic effect, which is why the effect is so much more pronounced at the nanoscale compared to the macroscale.

To further test whether the anelasticity was rooted in impurities, the team tested wires made from a different material–silicon doped with boron impurities. Like the zinc oxide nanowires, the doped silicon also proved to be anelastic.

The findings suggest that anelasticity is likely a common property of single-crystal nanowires. “One reviewer [of our paper] commented that this is a new important page in the book on mechanics of nanostructures,” Zhu said. “The factors that favor anelasticity, such as high strain gradient, short diffusion distance and large diffusivity of point defects, are all prominently present in nanowires”.

###

Other authors on the paper were Guangming Cheng, Qingquan Qin, Jing Li, Feng Xu and Elizabeth C. Dickey from NC State, and Chunyang Miao and Hamed Haftbaradaran from Brown.

The research was supported by the National Science Foundation.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

“Nanostitches” enable lighter and tougher composite materials

In research that may lead to next-generation airplanes and spacecraft, MIT engineers used carbon nanotubes to prevent cracking in multilayered composites. To save on fuel and reduce aircraft emissions, engineers…

Trash to treasure

Researchers turn metal waste into catalyst for hydrogen. Scientists have found a way to transform metal waste into a highly efficient catalyst to make hydrogen from water, a discovery that…

Real-time detection of infectious disease viruses

… by searching for molecular fingerprinting. A research team consisting of Professor Kyoung-Duck Park and Taeyoung Moon and Huitae Joo, PhD candidates, from the Department of Physics at Pohang University…