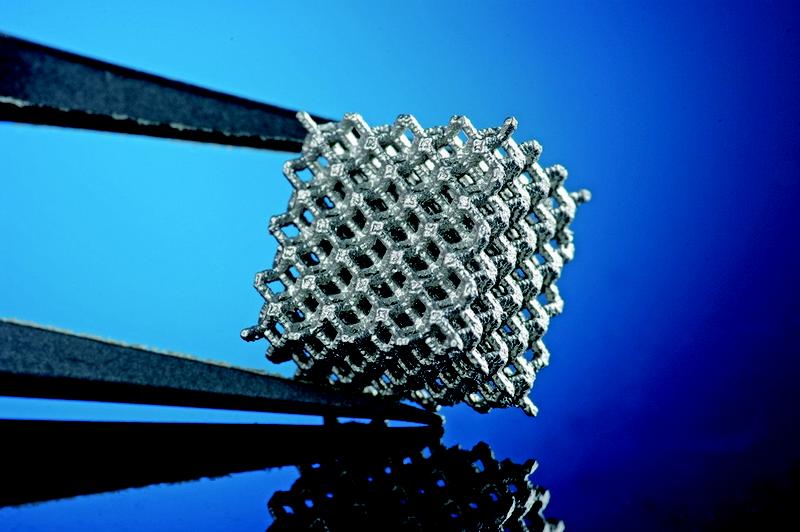

Picture 1: Implant (scaffold) with defined pore structure made from biodegradable magnesium alloy (WE43). It measures 10x10x7.5 mm³ with a strut thickness of approx. 400 µm.

© Fraunhofer ILT, Aachen, Germany / Volker Lannert.

Selective laser melting with “normal” materials such as stainless steel, aluminum or titanium alloys has already come of age in the world of production. The materials and processes have been extensively researched, and the related machinery is available from a number of vendors.

Things only get difficult when attempting to work with other materials such as Magnesium. It is not only 30% lighter than aluminum, but it can also be used to produce resorbable implants, thus making it extremely desirable for use in lightweight construction and medical technology applications.

Experts at Fraunhofer ILT have developed a processing technique that now makes it possible to work difficult materials using SLM. To combat heavy smoke formation, a new process chamber featuring optimized shielding gas flow was developed in cooperation with ILT spinoff Aconity3D for use with magnesium alloys. In addition, processes for use with copper alloys were optimized, as were special systems with high-temperature preheating for use with crack-prone and difficult-to-weld metals.

SLM allows for bioresorbable magnesium alloy implants

Desirable features of implants, such as tailored designs and complex structures, can be produced at no extra expense using SLM. As a material, magnesium offers the added advantage of being resorbable by the human body. Implants based on solid magnesium materials are already in use, but further benefits are promised for implants with pore structure.

The idea here is that new bony material will grow into the implant, while at the same time the metallic material is resorbed by the body. Fraunhofer ILT has developed an SLM process for magnesium alloy implants of this type, in which both the exact shape and pore size of the implant can be chosen. The biocompatibility of the implant prototypes has already been demonstrated in vitro.

While Fraunhofer ILT continues to research new materials and processes, SLM equipment for magnesium alloys is already available from Aconity3D.

Lighter and stronger: SLM allows for full topology optimization

The advantages of magnesium alloys have long been known in the worlds of aerospace and motorsports. These materials are 30% lighter than aluminum, yet they are also much more difficult to work.

The new SLM processing technique solves this problem in an elegant fashion. To explore the concept in detail, Fraunhofer ILT constructed a motorcycle triple clamp in 1:4 scale, by optimizing the entire topology of the component by computer. The objective here is to achieve full structural and weight optimization for comparable lightweight parts.

This represents one of the world’s first example of complex components made from magnesium alloys. In terms of quality, they are equal to other SLM products, yet with respect to strength they are even superior to cast parts.

This opens the door to new applications not only in lightweight construction, but also in medical technology, such as custom-made surgical bone replacements for cranio maxillofacial applications.

SLM live at AKL’16

In addition to magnesium alloys, research work is continuing on developing SLM for processing novel materials such as high-temperature alloys for turbomachinery applications or copper alloys. The various processes will be exhibited at the International Laser Technology Congress AKL’16 in Aachen.

As a part of the exhibition, Fraunhofer ILT will be once again offering around 70 “Laser Technology Live” presentations in addition to talks with subject area experts at its Application Center.

Events

International Laser Technology Congress AKL’16

April 27-29, 2016

Eurogress

Monheimsallee 48

52062 Aachen

Germany

www.lasercongress.org

Laser Technology Live

April 27, 2016, 16:30

Fraunhofer Institute for Laser Technology ILT

Steinbachstraße 15

52074 Aachen

Germany

www.ilt.fraunhofer.de

Contact

Dipl.-Phys. Lucas Jauer

Rapid Manufacturing Group

Phone +49 241 8906-360

lucas.jauer@ilt.fraunhofer.de

Dr.-Ing. Wilhelm Meiners

Group Manager Rapid Manufacturing

Phone +49 241 8906-301

wilhelm.meiners@ilt.fraunhofer.de

http://www.ilt.fraunhofer.de/en.html