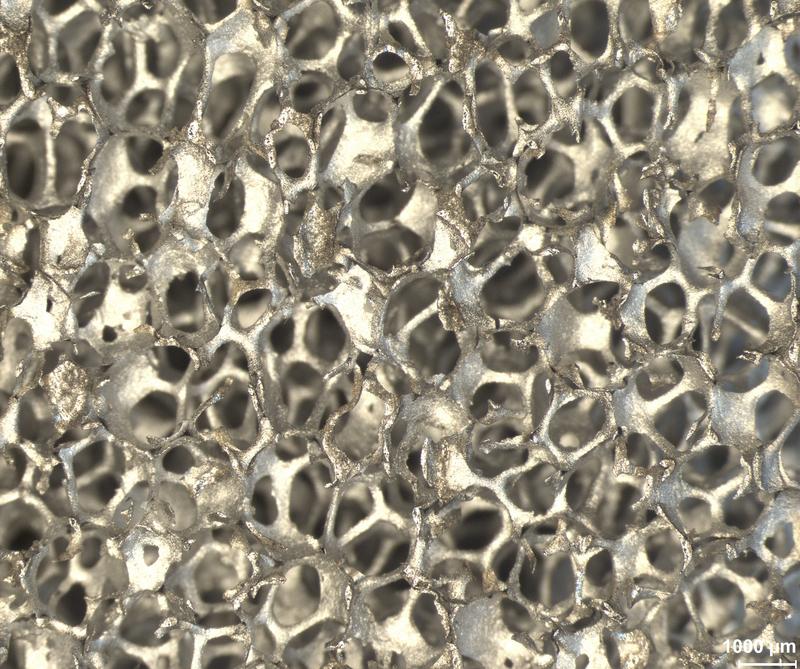

Open-cell metal foam can be used in heat exchangers, convectors and coolers.

© Fraunhofer IFAM Dresden

Open-pore metal foams offer greater heat transfer

A liquid or gas circulates within many heating technology components to provide a heat transfer medium. In contrast to the meandering tube bundles or fins previously usually deployed in the components, open-pore metal foams have the advantage that they have a greater surface. This facilitates the transfer of large amounts of heat.

The metal foams can be made with cell widths between 0.3 and 5 mm. The production begins with open-cell polyurethane foams. These are cast in a liquid ceramic suspension. The plastic inside is then burnt by heating. The resulting mould can be filled with various metal alloys using precision casting or powder metallurgical processes.

Open-pore metal foams can be used, for example, in car radiators, high-performance evaporators and latent heat storage systems. The Fraunhofer Institute for Manufacturing Technology and Advanced Materials in Dresden is carrying out the research in collaboration with industrial partners.

You found all informations about the BINE Projektinfo brochure entitled “Metal foam – a material for heat engineering” here:

http://www.bine.info/en/press/press-releases/press/pressemitteilung/waermetechni…

Uwe Milles/Birgit Schneider

presse(at)bine.info

About BINE Information Service

Energy research for practical applications

The BINE Information Service reports on energy research topics, such as new materials, systems and components, as well as innovative concepts and methods. The knowledge gained is incorporated into the implementation of new technologies in practice, because first-rate information provides a basis for pioneering decisions, whether in the planning of energy-optimised buildings, increasing the efficiency of industrial processes, or integrating renewable energy sources into existing systems.

About FIZ Karlsruhe

FIZ Karlsruhe – Leibniz Institute for Information Infrastructure is a not-for-profit organization with the public mission to make sci-tech information from all over the world publicly available and to provide related services in order to support the national and international transfer of knowledge and the promotion of innovation.

Our business areas:

• STN International – the world’s leading online service for research and patent information in science and technology

• KnowEsis – innovative eScience solutions to support the process of research in all its stages, and throughout all scientific disciplines

• Databases and Information Services – Databases and science portals in mathematics, computer science, crystallography, chemistry, and energy technology

FIZ Karlsruhe is a member of the Leibniz Association (WGL) which consists of 87 German research and infrastructure institutions.

http://www.bine.info/en – BINE Informationsdienst