Identifying Atomic Species on Anatase Titanium Dioxide Surface

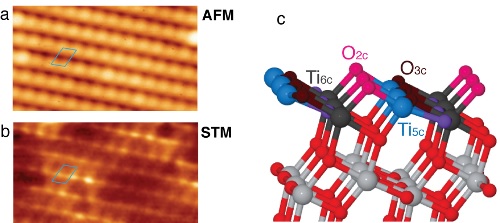

Simultaneous atomic-scale AFM (a) and STM (b) images of the (101) surface of anatase titanium dioxide. The parallelograms indicate the same surface area in (a) and (b). The positions of maximum signal (bright spots) in the AFM and STM images clearly differ. By using single water molecules as atomic markers and combining simultaneous AFM and STM measurements with first-principles calculations, the authors demonstrated that the AFM images the first atomic layer of oxygen atoms-pink spheres in the model of the anatase (101) surface depicted in (c)-and the STM images the titanium atoms at the third atomic layer-dark gray spheres in (c). Copyright : NIMS

The study contributes to formulate novel approaches for the development of photo-catalysts and solar energy conversion materials.

The research team consisting of Oscar Custance and Tomoko Shimizu, group leader and senior scientist, respectively, at the Atomic Force Probe Group, NIMS, Daisuke Fujita and Keisuke Sagisaka, group leader and senior researcher, respectively, at the Surface Characterization Group, NIMS, and scientists at Charles University in the Czech Republic, Autonomous University of Madrid in Spain, and other organizations combined simultaneous atomic force microscopy (AFM) and scanning tunneling microscopy (STM) measurements with first-principles calculations for the unambiguous identification of the atomic species at the most stable surface of the anatase form of titanium dioxide (hereinafter referred to as anatase) and its most common defects.

In recent years, anatase has attracted considerable attention, because it has become a pivotal material in devices for photo-catalysis and for the conversion of solar energy to electricity. It is extremely challenging to grow large single crystals of anatase, and most of the applications of this material are in the form of nano crystals.

To enhance the catalytic reactivity of anatase and the efficiency of devices for solar energy conversion based on anatase, it is critical to gain in-depth understanding and control of the reactions taking place at the surface of this material down to the atomic level. Only a few research groups worldwide possess the technology to create proper test samples and to make in-situ atomic-level observations of anatase surfaces.

In this study, the research team used samples obtained from anatase natural single crystals extracted from naturally occurring anatase rocks. The team characterized the (101) surface of anatase at atomic level by means of simultaneous AFM and STM.

Using single water molecules as atomic markers, the team successfully identified the atomic species of this surface; result that was additionally confirmed by the comparison of simultaneous AFM and STM measurements with the outcomes of first-principles calculations.

In regular STM, in which an atomically sharp probe is scanned over the surface by keeping constant an electrical current flowing between them, it is difficult to stably image anatase surfaces as this material presents poor electrical conductivity over some of the atomic positions of the surface.

However, simultaneous operation of AFM and STM allowed imaging the surface with atomic resolution even within the materials band gap (a region where the flow of current between the probe and the surface is, in principle, prohibited). Here, the detection of inter-atomic forces between the last atom of the atomically sharp probe and the atoms of the surface by AFM was of crucial importance.

By regulating the probe-surface distance using AFM, it was possible to image the surface at atomic-scale while collecting STM data over both conductive and not conductive areas of the surface. By comparing simultaneous AFM and STM measurements with theoretical simulations, the team was not only able to discern which atomic species were contributing to the AFM and the STM images but also to identify the most common defects found at the surface.

In the future, based on the information gained from this study, the NIMS research team will conduct research on molecules of technologically relevance that adsorb on anatase and characterize these hybrid systems by using simultaneous AFM and STM. Their ultimate goal is to formulate novel approaches for the development of photo-catalysts and solar cell materials and devices.

This study was published under open access policy in the online version of Nature Communications on June 29, 2015.

Associated links

Original press release from NIMS