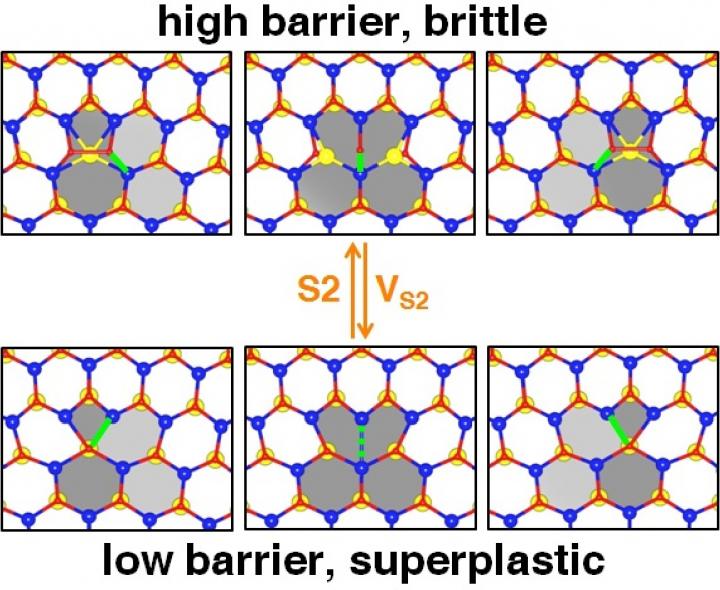

Calculations by Rice University scientists show that a two-dimensional layer of molybdenum disulfide can become superplastic by changing its environmental conditions. In an atmosphere with sulfur and under the right temperature and pressure, the energy barrier is lowered, allowing dislocations along the grain boundaries to shift and changing the material's properties. S2 refers to a disulfur molecule; VS2 is a two-sulfur-atom vacancy.

Credit: Xiaolong Zou/Rice University

What if peanut brittle, under certain conditions, behaved like taffy? Something like that happens to a two-dimensional dichalcogenide analyzed by scientists at Rice University.

Rice researchers calculated that atomically thin layers of molybdenum disulfide can take on the qualities of plastic through exposure to a sulfur-infused gas at the right temperature and pressure.

That means one can deform it without breaking it — a property many materials scientists who study two-dimensional materials should find interesting, according to Rice theoretical physicist Boris Yakobson and postdoctoral researcher Xiaolong Zou; they led the study that appeared in the American Chemical Society journal Nano Letters.

Molybdenum disulfide, the object of study in many labs for its semiconducting properties, interested the Rice lab because of the characteristics of its grain boundaries. Two-dimensional materials like graphene are actually flat, atom-thick sheets. But 2-D molybdenum disulfide is a sandwich, with layers of sulfur above and below the molybdenum atoms.

When two sheets join at different angles during growth in a furnace, atoms at the boundaries have to compensate by improvising “defective” arrangements, called dislocations, where they come together.

The researchers determined it may be possible to promote the movement of those dislocations through environmental control of the gas medium. This would change the material's properties to give it superplasticity, which allows it to be deformed beyond its usual breaking point.

Plastic materials can be rearranged and will hold their new shape. For example, a plumber can bend a metal pipe; that bendable quality is plasticity. Yakobson noted such materials can become brittle again with further changes in the environment.

“Generally, the coupling of chemistry and mechanics is quite rare and scientifically difficult to understand,” said Yakobson, whose group at Rice analyzes materials by calculating the energies that bind their atoms. “Corrosion is the best example of how chemistry affects mechanical behavior, and the science of corrosion is still in development.”

For molybdenum disulfide, they found two mechanisms by which boundaries could overcome activation energy barriers and lead to superplasticity. In the first, called direct rebonding, only one molybdenum atom in a dislocation would shift in response to external forces. In the second, bond rotation, several atoms would shift in opposite directions.

They calculated that the barrier for direct rebonding, while less dramatic, is much lower than for bond rotation. “Through the rebonding path, the mobility of this defect changes by several orders of magnitude,” Yakobson said. “We know from the mechanics of materials that brittle or ductile qualities are defined by the mobility of these dislocations. What we show is that we can affect the tangible property, the stretchability, of the material.”

Yakobson suggested it may be possible to tune the plasticity of dichalcogenides in general and that it may also be possible to eliminate the defects from a 2-D dichalcogenide sheet by treating the dislocations “to allow them to rapidly diffuse away and vanish or to form interesting aggregated states.” That would likely open the way to the easier manufacture of dichalcogenides that need particular electrical or mechanical properties for applications, he said.

“We think of these two-dimensional materials as an open canvas, theoretically speaking,” he said. “You can very quickly read and write changes to them. Bulk materials don't have this openness, but here, every atom is in immediate proximity to the environment.”

###

Rice graduate student Mingjie Liu and Zhiming Shi, an exchange graduate student in Yakobson's group from Jilin University, Changchun, China, are co-authors of the paper. Yakobson is Rice's Karl F. Hasselmann Professor of Materials Science and NanoEngineering, a professor of chemistry and a member of Rice's Richard E. Smalley Institute for Nanoscale Science and Technology.

A Multidisciplinary University Research Initiative grant through the United States Army Research Office and the Robert Welch Foundation supported the research. The researchers utilized the National Science Foundation-supported DAVinCI supercomputer administered by Rice's Ken Kennedy Institute for Information Technology.

Read the abstract at http://pubs.

This news release can be found online at http://news.

Follow Rice News and Media Relations via Twitter @RiceUNews

Related Materials:

Yakobson Research Group: http://biygroup.

Department of Materials Science and NanoEngineering: http://msne.