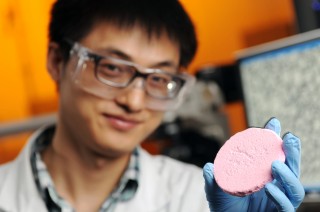

Credit: Gary Meek

Yi Zhang, a graduate student co-advised by Prof. Sven Behrens and Prof. Carson Meredith in the School of Chemical & Biomolecular Engineering at Georgia Tech, is shown holding a porous solid material prepared from a capillary foam.

At its most basic level, foam is a bunch of bubbles squished together. Liquid foams, a state of matter that arises from tiny gas bubbles dispersed in a liquid, are familiar in everyday life, from beer to bathwater.

They also are important in commercial products and processes, including pharmaceutical formulation, oil production, food processing, cleaning products, cosmetics, or hair and skin care products. Lightweight dry foams for the construction of buildings, automobiles and airplanes are key materials in the push for sustainability and energy efficiency. Making lightweight foam has one big challenge, however, keeping the foam stable.

A team of researchers from the Georgia Institute of Technology has developed a new type of foam – called capillary foam – that solves many of the problems faced by traditional foams. The new research shows for the first time that the combined presence of particles and a small amount of oil in water-based foams can lead to exceptional foam stability when neither the particles nor the oil can stabilize the foams alone.

“It’s very difficult to stabilize foams, and we want foams that are stable for months or years,” said Sven Behrens, study co-author and professor in the School of Chemical and Biomolecular Engineering at Georgia Tech. “We’ve developed a way to make foams that is much easier and more broadly applicable that what is traditionally used.”

The study was sponsored by the National Science Foundation (NSF). The research was published online October 3, 2014, in the journal Angewandte Chemie. The new capillary foams were developed by graduate student Yi Zhang, who is co-advised by Behrens and Carson Meredith, also a professor in the School of Chemical and Biomolecular Engineering.

The main ingredients for foam are air and water. Surfactants, which are similar to detergents, are then traditionally added to stabilize foams. Another traditional way to stabilize foam is to add microscopic particles, like talc powder. Both approaches require that the additive have a specific set of properties, which isn’t always possible with the materials available.

The new study demonstrates how the addition of a tiny amount of oil allows the use of particles with more general properties.

“It sounds like we’re making the system more complicated by adding oil to the mix, but it’s a small amount of oil that could be something as simple as vegetable oil,” Meredith said.

The new capillary foams expand the range of particles useful for stabilizing foams that are made of air and water. Air bubbles are stabilized by the combined action of the particles and the small amount of oil. This synergy of oil and particulate is counterintuitive because oils usually decrease foam stability and are commonly used as defoaming agents. But like the water-bridged grains of sand that hold a sand castle together, particles in the capillary foam form a stabilizing network connected by oil bridges.

“This is a novel phenomenon that people haven’t discussed before, so we need to know more about why this works,” Meredith said.

Lightweight dry foams made by this process could be used in many industries, from construction to automobile and airplane manufacturing.

“We’re looking at several different application areas where it could be used as a product,” Behrens said.

This research is supported by the Renewable Bioproducts Institute of Georgia Tech, by the National Science Foundation (awards CBET-1134398 and CBET-1160138), and by the Air Force Office of Scientific Research under award number FA9550-10-1-0555. Any conclusions or opinions are those of the authors and do not necessarily represent the official views of the sponsoring agencies.

CITATION: Yi Zhang, et. al., “A new class of liquid foams stabilized by synergistic action of particles and immiscible liquid.” (September 2014, Angewandte Chemie) http://dx.doi.org/10.1002/ange.201405816

Research News

Georgia Institute of Technology

177 North Avenue

Atlanta, Georgia 30332-0181 USA

@GTResearchNews

Media Relations Contacts: Brett Israel (@btiatl) (404-385-1933) (brett.israel@comm.gatech.edu) or John Toon (404-894-6986) (jtoon@gatech.edu)

Writer: Brett Israel

![[1] Key Research Findings on Transfer-Printed Alumina–Gold Dual-layer Protective Coating](https://www.innovations-report.com/wp-content/uploads/2025/07/Transfer_printing_technology_for_lithium_protectiv_1753252750-e1753252940671-362x245.jpg)