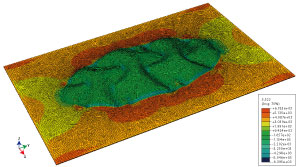

A finite element simulation of a viscoelastic dielectric elastomer actuator, which undergoes wrinkling under voltage. © 2016 A*STAR Institute of High Performance Computing

Robotic devices are usually composed of hard components such as aluminum and steel, in contrast to the soft tissues that power biological organisms. A study conducted by A*STAR researchers now makes it easier to turn squishy, electroactive polymers into artificial muscles and biomimetic energy harvesters through computer-aided design [1].

Dielectric elastomers are rubbery, insulating membranes that respond dramatically to electric fields — when sandwiched between two electrodes, they can expand by several hundred per cent in a two-dimensional plane. These special deformation properties have led to applications such as soft-body robotics and sensors. However, the shape-shifting membranes often develop changes in their electrically stimulated response over time, making them hard to optimize for long-term use.

Keith Choon Chiang Foo from the A*STAR Institute of High Performance Computing and his team realized that numerical simulations could help to improve dielectric elastomer devices. They turned to finite element analysis, a tool that predicts the performance of complex objects by modeling them as small interconnected geometric units, to reach this goal. But finding algorithms that replicate smart polymer behavior is not straightforward.

“Existing finite element software doesn’t have the capability to simulate soft rubbery materials that respond to electricity and involve large deformations,” says Foo. “Plus, most simulations of these polymers have been done using ‘in-house’ software, meaning source codes are not available to the scientific community.”

The researchers solved these issues with a model that revealed how repeated movements affected the membrane’s ability to respond to electricity and mechanical forces over time. Their algorithms coupled this property, known as viscoelasticity, to electrostatic charges in the device. They implemented this model into commercial finite element software. “We have made the subroutine freely available to aid other researchers,” adds Foo.

The team’s simulations highlighted examples where viscoelasticity has an impact on the performance of artificial muscle-like devices. For example, when an electrical pulse causes the membrane to stretch out, the elastomer takes a characteristic time to relax to the new configuration. If the pulse cycles at a rate close to this relaxation time, mechanical actuation can be significantly affected.

Further tests showed the improved finite element analysis could quantify the critical time delay between the instant an electrical signal is applied and the maximum polymer actuation achieved. Because the computations agree well with previous experimental data, Foo is confident this technique can reduce trial-and-error approaches to biomimetic devices.

“This simulation tool may prove very capable,” he remarks. “When we work with experimentalists, it helps guide our approach to soft machines.”

The A*STAR-affiliated researchers contributing to this research are from the Institute of High Performance Computing. For more information about the team’s research, please visit the Soft Matter Group webpage.

Reference

[1] Foo, C. C. & Zhang, Z.-Q. A finite element method for inhomogeneous deformation of viscoelastic dielectric elastomers. International Journal of Applied Mechanics 7, 1550069 (2015).

Associated links