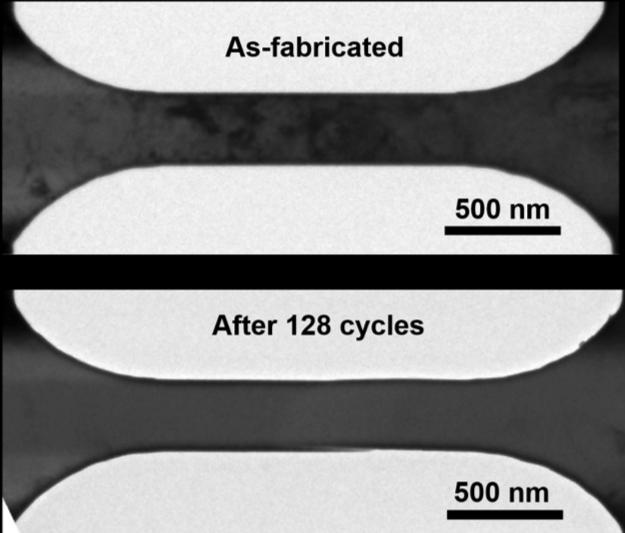

These are bright-field images of aluminum single crystal before (top) and after mechanical healing (bottom).

Credit: MIT

An international team of researchers, including Carnegie Mellon University President Subra Suresh, Zhiwei Shan and colleagues from Xi'an Jiaotong University in China, Ming Dao and Ju Li from MIT, and Evan Ma from Johns Hopkins University, has developed a new technique called cyclic healing that uses repetitive, gentle stretching to eliminate pre-existing defects in metal crystals.

Their results have been published online today (Monday, Oct. 19) in the Proceedings of the National Academy of Sciences.

Most materials are made of crystals. When materials fail, it is usually the result of defects in the crystal or in the arrangement of multiple crystals in a polycrystalline structure. While much research has been done on metal fatigue at larger scales, new technologies are just now allowing researchers to see how atomic-scale defects nucleate, multiply and interact in materials subjected to monotonic or fatigue loading inside a high-resolution microscope.

In this study, the researchers used transmission electron microscopy to look inside sub-micrometer-sized specimens of aluminum crystals as they subjected the samples to stressors like repeated, small-amplitude deformation or fatigue loading.

They found that gentle cyclic deformation, a process that repetitively stretches the crystal, helps to unpin or shakedown rows of atomic defects known as dislocations in the metal and move these dislocations closer to free surfaces in the sample.

Image forces, which act to minimize the energy of the defects, attract the dislocations closer to the free surfaces and force them out of the crystal. As a result, the crystal “heals,” becoming essentially free of pre-existing dislocations, thereby significantly increasing its strength.

This finding was surprising to researchers because cyclic deformation has an opposite effect in micro- and macro-scale metal crystals. In these larger samples, repeated stretching generally leads to the creation, accumulation and interaction of defects, which can lead to cracking and failure.

“This work demonstrates how cyclic deformation, under certain controlled conditions, can lead to the removal of defects from crystals of small volume,” says Suresh, who holds the Henry L. Hillman President's Chair at CMU. “It also points to potential new pathways for engineering the defect structure of metal components in a variety of sub-micro-scale systems.”

###

The research was supported by the National Science Foundation (DMR-1120901 and DMR-1410636) , the 973 Programs of China, the U.S. Department of Energy, and the Singapore-MIT Alliance for Research and Technology.