Ceramic particles supply digital X-ray plates “from an aerosol can”

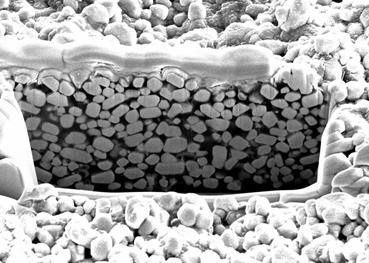

Distribution of the ceramic particles in the plastic visualized by electron microscopy.

Source: INM; only free within this press release

Now, scientists collaborating in project HOP-X have succeeded in developing new materials for detectors: they embedded ceramic particles in a conductive plastic. The components of these “composite detectors” can be stirred into a solvent and then applied like paint by spraying. This means that, in future, it might be possible to manufacture X-ray detectors inexpensively and on a large scale with greater image resolution.

These results were recently published in the magazine “Nature Photonics”.

X-ray detectors consist of a scintillator layer and a photodiode. The scintillator layer converts X-rays into visible light which the photodiode absorbs. Such detectors are difficult to manufacture and expensive.

Their resolution is limited because the signals received can interfere with each other. In order to manufacture X-ray detectors at lower cost, scientists from Siemens Healthcare GmbH, the INM –Leibniz Institute for New Materials, the CAN GmbH, the Universities of Erlangen and further partners took a new approach in the project HOP-X: they used materials developed for flexible solar cells and adapted them to the X-rays.

For this purpose, the scientists at INM manufactured ceramic particles which light up when X-rays hit them. They embedded these in a conductive plastic. It converts the light into an electric current which is registered by the X-ray apparatus. The researchers investigated the composite material formed by the particles and the plastic.

“We examined the samples with electron microscopy using thin layers cut out of the composite with ion beams,” explains Tobias Kraus, Division Head for Structure Formation at INM. “The images we got show how the particles arrange inside the plastic at different mixing ratios. This enabled our partners to select the mixing ratios to make the most sensitive of X-ray detectors.” The optimized materials yield high-resolution X-ray images already at a low radiation dosage.

The results show that X-ray detectors made of new composite materials can fulfill the strict requirements of medical technology. The researchers are currently working on process techniques to allow the manufacture of larger detectors.

Background:

Besides the INM, Siemens Healthcare GmbH, Merck KgaA and CAN GmbH participated in the HOP-X project. The three-year collaborative project HOP-X, which was concluded in autumn 2015, received financial assistance from the German Federal Ministry of Education and Research to the amount of 1.86 million euros.

Original publications:

Patric Büchele, Moses Richter, Sandro F. Tedde, Gebhard J. Matt, Genesis N. Ankah, Rene Fischer, Markus Biele, Wilhelm Metzger, Samuele Lilliu, Oier Bikondoa, J. Emyr Macdonald, Christoph J. Brabec, Tobias Kraus, Uli Lemmer, Oliver Schmidt: „X-ray imaging with scintillator-sensitized hybrid organic photodetectors“; Nature Photonics, DOI: 10.1038/nphoton.2015.216

Your expert at the INM:

Dr. Tobias Kraus

INM – Leibniz Institute for New Materials

Head Structure Formation

Deputy Head InnovationCenter INM

Tel.: +49 681-9300-389

tobias.kraus@leibniz-inm.de

INM conducts research and development to create new materials – for today, tomorrow and beyond. Chemists, physicists, biologists, materials scientists and engineers team up to focus on these essential questions: Which material properties are new, how can they be investigated and how can they be tailored for industrial applications in the future? Four research thrusts determine the current developments at INM: New materials for energy application, new concepts for medical surfaces, new surface materials for tribological systems and nano safety and nano bio. Research at INM is performed in three fields: Nanocomposite Technology, Interface Materials, and Bio Interfaces.

INM – Leibniz Institute for New Materials, situated in Saarbrücken, is an internationally leading centre for materials research. It is an institute of the Leibniz Association and has about 210 employees.

http://www.leibniz-inm.de/en

http://www.leibniz-gemeinschaft.de/en/home/