NIST sensor experts invent supercool mini thermometer

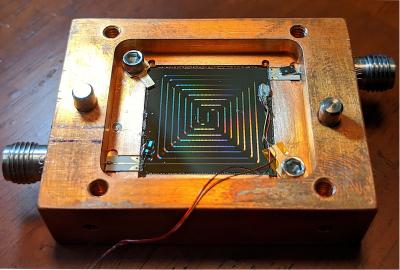

Two of NIST's superconducting thermometers for measuring cryogenic temperatures are glued to the lower left and upper right of this amplifier. The miniature thermometers, made of niobium on a layer of silicon dioxide, measure the temperature of the amplifier or other device based on a frequency signal.

Credit: Wheeler/NIST

Researchers at the National Institute of Standards and Technology (NIST) have invented a miniature thermometer with big potential applications such as monitoring the temperature of processor chips in superconductor-based quantum computers, which must stay cold to work properly.

NIST’s superconducting thermometer measures temperatures below 1 Kelvin (minus 272.15 ?C or minus 457.87 ?F), down to 50 milliKelvin (mK) and potentially 5 mK. It is smaller, faster and more convenient than conventional cryogenic thermometers for chip-scale devices and could be mass produced. NIST researchers describe the design and operation in a new journal paper [https:/

Just 2.5 by 1.15 millimeters in size, the new thermometer can be embedded in or stuck to another cryogenic microwave device to measure its temperature when mounted on a chip. The researchers used the thermometer to demonstrate fast, accurate measurements of the heating of a superconducting microwave amplifier.

The technology is a spinoff of NIST’s custom superconducting sensors for telescope cameras, specifically microwave detectors delivered for the BLAST balloon [https:/

“This was a fun idea that quickly grew into something very helpful,” group leader Joel Ullom said. “The thermometer allows researchers to measure the temperature of a wide range of components in their test packages at very little cost and without introducing a large number of additional electrical connections. This has the potential to benefit researchers working in quantum computing or using low-temperature sensors in a wide range of fields.”

The thermometer consists of a superconducting niobium resonator coated with silicon dioxide. The coating interacts with the resonator to shift the frequency at which it naturally vibrates. Scientists suspect this is due to atoms “tunneling” between two sites, a quantum-mechanical effect.

The NIST thermometer is based on a new application of the principle that the natural frequency of the resonator depends on the temperature. The thermometer maps changes in frequency, as measured by electronics, to a temperature. By contrast, conventional thermometers for sub-Kelvin temperatures are based on electrical resistance. They require wiring routed to room-temperature electronics, adding complexity and potentially causing heating and interference.

The NIST thermometer measures temperature in about 5 milliseconds (thousandths of a second), much faster than most conventional resistive thermometers at about one-tenth of a second. The NIST thermometers are also easy to fabricate in only a single process step. They can be mass produced, with more than 1,200 fitting on a 3-inch (approximately 75-millimeter) silicon wafer.

###

Paper:

J. Wheeler, M.R. Vissers, M. Malnou, J. Hubmayr, J.N. Ullom, and J. Gao. Sub-Kelvin Thermometer for On-Chip Measurements of Microwave Devices Utilizing Two-Level Systems in Superconducting Microresonators. Applied Physics Letters 117, 192601 (2020). DOI: 10.1063/5.0029351 [https:/

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…