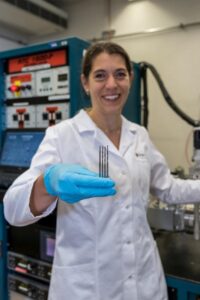

Sensitive drills

A sensitive drill for cochlear implants.

(c) Empa

Hearing-impaired people whose auditory nerve is still intact can often be helped with a cochlear implant. But inserting the implant into the inner ear is not without risks, as facial nerves can be damaged in the process. Empa researchers have developed a novel smart drill that minimizes the risk by automatically shutting off when it comes near nerves.

(c) Empa

Methods of Advanced Manufacturing can lead to remarkable advances in surgery. A group of researchers led by Stefan Weber of the University of Bern’s ARTORG Center for Biomedical Engineering Research has developed a robot that can insert cochlear implants more gently than a surgeon. “When a surgeon performs the procedure, he has to remove relatively large areas of the skull bone,” Weber explained in an article in the NZZ. Only when he can see where the nerves are located will he use the drill, he said. The robot, on the other hand, drills only a 1.8 millimeter wide channel, the course of which is determined on the basis of a previously created CT image.

But the surgeons must not drill at random, because the hole for the cochlear implant must lie exactly between the taste nerve and the facial nerve. At one point, these nerves are only three millimeters apart and must not be damaged under any circumstances. Until now, surgeons proceeded like this: Just before the constriction, they stopped drilling and irritated the facial nerve with an electric tip. If the twitching in the patient’s face is not too strong, drilling can continue carefully.

Drill and stimulator at the same time

The physicians at the ARTORG Center approached Empa with the question: Couldn’t we develop a drill that would also electrically stimulate the facial nerve, i.e. a drill that would indicate its position in the patient’s skull? Kerstin Thorwarth from Empa’s Surface Science and Coating Technologies lab went to work. Together with a colleague, she developed a drill with a conductive tip as part of a master’s thesis and an Innosuisse project. The conductive and insulating hard coatings of titanium nitride (TiN) and silicon nitride (Si3N4) were applied to the drill tip by magnetron sputtering. For this, the individual windings of the drill had to be covered with special masks.

Not yet certified for medical applications

The drill with the special surface developed at Empa finally exhibited the appropriate electrical properties and also passed drilling tests in bone material carried out in the laboratory. The partners in Bern were pleased. “The smart drill for cochlear surgery could also be used for spinal surgery, for example,” says project leader Stefan Weber.

Now the Empa researchers are working with the surgeons to find an industrial partner who can manufacture the smart drill in accordance with the legal requirements for medical devices. “This will require further significant development effort,” says Weber. And that still needs to be funded.

Wissenschaftliche Ansprechpartner:

Dr. Kerstin Thorwarth

Surface Science & Coating Technologies

Phone: +41 58 765 4547

kerstin.thorwarth@empa.ch

Prof. Dr. Stefan Weber

ARTOG Center for Biomedical Engineering Research

Chair for Image-guided Therapy

stef.weber@unibe.ch

Weitere Informationen:

https://www.empa.ch/web/s604/smart-drill Empa media release

Media Contact

All latest news from the category: Medical Engineering

The development of medical equipment, products and technical procedures is characterized by high research and development costs in a variety of fields related to the study of human medicine.

innovations-report provides informative and stimulating reports and articles on topics ranging from imaging processes, cell and tissue techniques, optical techniques, implants, orthopedic aids, clinical and medical office equipment, dialysis systems and x-ray/radiation monitoring devices to endoscopy, ultrasound, surgical techniques, and dental materials.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…