A 3D printed vaccine patch offers vaccination without a shot

Scientists at the University of North Carolina at Chapel Hill and Stanford University use 3D printer to produce microneedle vaccine patch that dissolves into the skin to boost immunity.

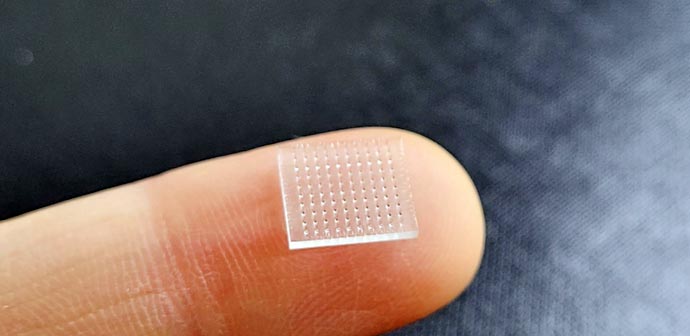

Credit: University of North Carolina at Chapel Hill

Stanford University and the University of North Carolina Chapel Hill develop microneedle vaccine patch that outperforms needle jab to boost immunity.

Scientists at Stanford University and the University of North Carolina at Chapel Hill have created a 3D-printed vaccine patch that provides greater protection than a typical vaccine shot.

The trick is applying the vaccine patch directly to the skin, which is full of immune cells that vaccines target.

The resulting immune response from the vaccine patch was 10 times greater than vaccine delivered into an arm muscle with a needle jab, according to a study conducted in animals and published by the team of scientists in the Proceedings of the National Academy of Sciences.

Considered a breakthrough are the 3D-printed microneedles lined up on a polymer patch and barely long enough to reach the skin to deliver vaccine.

“In developing this technology, we hope to set the foundation for even more rapid global development of vaccines, at lower doses, in a pain- and anxiety-free manner,” said lead study author and entrepreneur in 3D print technology Joseph M. DeSimone, professor of translational medicine and chemical engineering at Stanford University and professor emeritus at UNC-Chapel Hill.

The ease and effectiveness of a vaccine patch sets the course for a new way to deliver vaccines that’s painless, less invasive than a shot with a needle and can be self-administered.

Study results show the vaccine patch generated a significant T-cell and antigen-specific antibody response that was 50 times greater than a subcutaneous injection delivered under the skin

That heightened immune response could lead to dose sparing, with a microneedle vaccine patch using a smaller dose to generate a similar immune response as a vaccine delivered with a needle and syringe.

While microneedle patches have been studied for decades, the work by Carolina and Stanford overcomes some past challenges: through 3D printing, the microneedles can be easily customized to develop various vaccine patches for flu, measles, hepatitis or COVID-19 vaccines.

Advantages of the vaccine patch

The COVID-19 pandemic has been a stark reminder of the difference made with timely vaccination. But getting a vaccine typically requires a visit to a clinic or hospital.

There a health care provider obtains a vaccine from a refrigerator or freezer, fills a syringe with the liquid vaccine formulation and injects it into the arm.

Although this process seems simple, there are issues that can hinder mass vaccination – from cold storage of vaccines to needing trained professionals who can give the shots.

Meanwhile vaccine patches, which incorporate vaccine-coated microneedles that dissolve into the skin, could be shipped anywhere in the world without special handling and people can apply the patch themselves.

Moreover, the ease of using a vaccine patch may lead to higher vaccination rates.

How the patches are made

It’s generally a challenge to adapt microneedles to different vaccine types, said lead study author Shaomin Tian, researcher in the Department of Microbiology and Immunology in the UNC School of Medicine.

“These issues, coupled with manufacturing challenges, have arguably held back the field of microneedles for vaccine delivery,” she said.

Most microneedle vaccines are fabricated with master templates to make molds. However, the molding of microneedles is not very versatile, and drawbacks include reduced needle sharpness during replication.

“Our approach allows us to directly 3D print the microneedles which gives us lots of design latitude for making the best microneedles from a performance and cost point-of-view,” Tian said.

The microneedle patches were 3D printed at the University of North Carolina at Chapel Hill using a CLIP prototype 3D printer that DeSimone invented and is produced by CARBON, a Silicon-Valley company he co-founded.

The team of microbiologists and chemical engineers are continuing to innovate by formulating RNA vaccines, like the Pfizer and Moderna COVID-19 vaccines, into microneedle patches for future testing.

“One of the biggest lessons we’ve learned during the pandemic is that innovation in science and technology can make or break a global response,” DeSimone said. “Thankfully we have biotech and health care workers pushing the envelope for us all.”

Additional study authors include Cassie Caudill, Jillian L. Perry, Kimon lliadis, Addis T. Tessema and Beverly S. Mecham of UNC-Chapel Hill and Brian J. Lee of Stanford.

Journal: Proceedings of the National Academy of Sciences

DOI: 10.1073/pnas.2102595118

Method of Research: Experimental study

Subject of Research: Animals

Article Title: Transdermal vaccination via 3D-printed microneedles induces potent humoral and cellular immunity

Article Publication Date: 24-Sep-2021

Media Contact

Shantell Kirkendoll

University of North Carolina at Chapel Hill

smkirken@email.unc.edu

Office: 919-445-8555

Original Source

https://uncnews.unc.edu/2021/09/23/a-3d-printed-vaccine-patch-offers-vaccination-without-a-shot/

All latest news from the category: Medical Engineering

The development of medical equipment, products and technical procedures is characterized by high research and development costs in a variety of fields related to the study of human medicine.

innovations-report provides informative and stimulating reports and articles on topics ranging from imaging processes, cell and tissue techniques, optical techniques, implants, orthopedic aids, clinical and medical office equipment, dialysis systems and x-ray/radiation monitoring devices to endoscopy, ultrasound, surgical techniques, and dental materials.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…