SUTD researchers developed a unique method of fabricating 3D porous structures

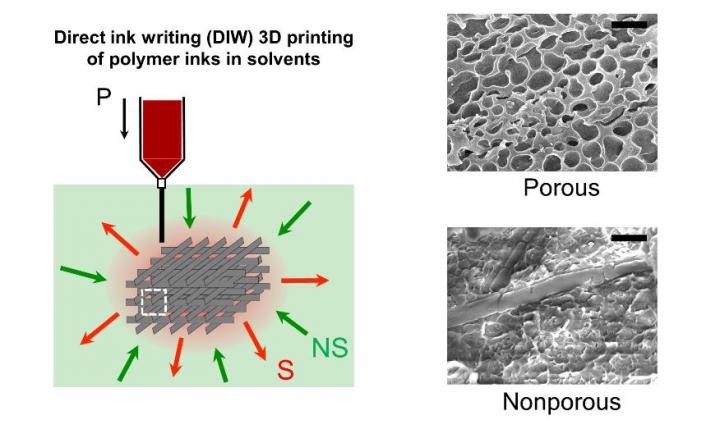

Concept of ip3DP - A polymer solution is printed by a DIW 3D printer in a nonsolvent. The printed object is solidified via immersion precipitation, and porosity is imparted to the printed object. Credit: SUTD

For example, the introduction of sacrificial templates can impart porosity to the materials encapsulating them after the removal of embedded materials. Alternatively, procedures involving phase separation, direct templating and chemical reaction have demonstrated fabrication of hierarchical porous structures. These methods inherently require multiple steps, and are limited in the attainable complexity of the fabricated structures.

Recent advances in digital fabrication, represented by 3D printing, has enabled fabrication of porous 3D structures consisting of polymeric materials with porosity, yet limited by materials applicable to the process.

For example, solvent-casting 3D printing (SC3DP)–direct 3D printing of polymer inks with in situ evaporation of solvents–has allowed fabrication of 3D porous structures with stringent requirement of rheological properties of the printing ink (e.g. high viscosity and high vapor pressure).

Researchers from the Singapore University of Technology and Design's (SUTD) Soft Fluidics Lab developed a novel 3D printing method to fabricate 3D porous models in one step, which was termed immersion precipitation 3D printing (ip3DP). In the newly developed approach, inks containing polymers were directly printed in a bath of a non-solvent, and the printed ink solidified rapidly via immersion precipitation.

Spontaneous solidification via immersion precipitation generated porosity at micro-to-nano scales. The porosity of the 3D printed objects is easily controlled by the concentrations of polymers and additives, and the types of solvents. A wider selection of solvents permitted a wider range of thermoplastics to be printed. To highlight this capability, fabrications of centimeter-scale models in 13 polymers dissolved in six solvents was demonstrated.

“This work is the first demonstration of three-dimensionally controlled immersion precipitation based on digitally controlled depositions of materials,” said lead author of the paper Dr Rahul Karyappa.

The principal investigator, Assistant Professor Michinao Hashimoto stated that “the wide selection of printable materials, and ability to tailor their morphologies and properties, make ip3DP a novel approach for 3D printing to fabricate functional structures.”

###

This work has been published online on July 8, 2019 in Materials Horizons, a leading journal that encourages exceptionally high quality, innovative materials science research. Akihiro Ohno, a research assistant at SUTD also participated in this research project.

Media Contact

More Information:

http://dx.doi.org/10.1039/C9MH00730JAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…