A waste product of the timber processing industry rethought

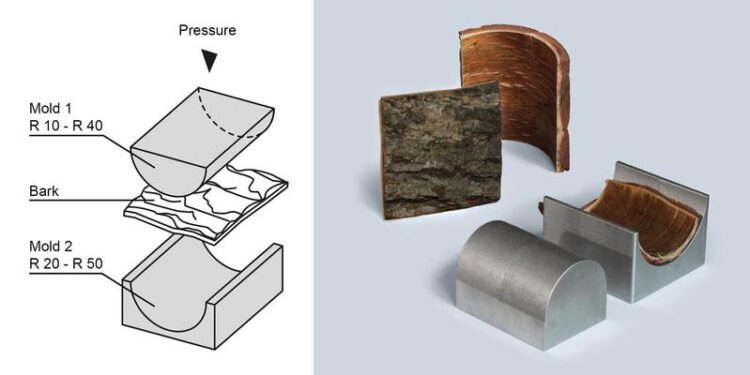

Manufacture of curved bark elements

(c) Dr. Charlett Wenig

© cc-by 4.0 PLOS ONE

An interdisciplinary team of researchers from the Max Planck Institute of Colloids and Interfaces (MPICI) has investigated how the natural properties of native tree bark can be used to create a standardized product for long-term use without the addition of adhesives. In doing so, they have created bark panels by peeling and drying via hot pressing, which could be used in interior design or furniture and packaging, for example, through industrial production.

With this processing method, the natural resource of tree bark could be further processed without the addition of artificial binders, such as adhesives, and without high energy expenditure. “A major advantage of ‘pure’ single-component products is that there is no need to separate the components after they have been used,” says Dr. Charlett Wenig, first author of the study. She adds, “Even if the structure of the raw material is changed, the basic building blocks remain the same and can therefore still be readily used for further processing, such as obtaining chemicals or fibers, or as fuel for energy production.”

Credit: Max-Planck-Institut für Kolloid- und Grenzflächenforschung/Dr. Charett Wenig

As a waste product of the timber industry, tree bark is available in large quantities. First, the bark must be peeled from the trunk and then dried. In the experiments, the scientists pressed the insides of the barks with a hydraulic press at 90 degrees Celsius. They used bark from the native tree species pine, larch, birch and oak. After pressing, all the bark panels produced in this way had a smooth surface comparable to sanded wood surfaces. The mechanical properties of the boards are comparable to those of a shelf board.

What is new? Previously, pure bark particle boards were made with the addition of formaldehyde-based adhesives or resins. As early as 1960, studies showed that it was possible to produce adhesive-free bark boards, but by using shredded bark pieces and by heavy processing. In the MPICI trials, researchers are taking advantage of the natural structural properties of the barks.

Partners: Eberswalde University of Applied Sciences (Department of Forest Utilization and Wood Market) and ETH Zurich (Wood Materials Science).

Originalpublikation:

Adhesives free bark panels: An alternative application for a waste material: https://doi.org/10.1371/journal.pone.0280721

Weitere Informationen:

https://www.mpikg.mpg.de/6787494/news_publication_19815874_transferred?c=132305 (Link to press release)

https://www.mpikg.mpg.de/en/plant-material-adaptation (Link to group page)

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Combatting disruptive ‘noise’ in quantum communication

In a significant milestone for quantum communication technology, an experiment has demonstrated how networks can be leveraged to combat disruptive ‘noise’ in quantum communications. The international effort led by researchers…

Stretchable quantum dot display

Intrinsically stretchable quantum dot-based light-emitting diodes achieved record-breaking performance. A team of South Korean scientists led by Professor KIM Dae-Hyeong of the Center for Nanoparticle Research within the Institute for…

Internet can achieve quantum speed with light saved as sound

Researchers at the University of Copenhagen’s Niels Bohr Institute have developed a new way to create quantum memory: A small drum can store data sent with light in its sonic…