3D battery imaging reveals the secret real-time life of lithium metal cells

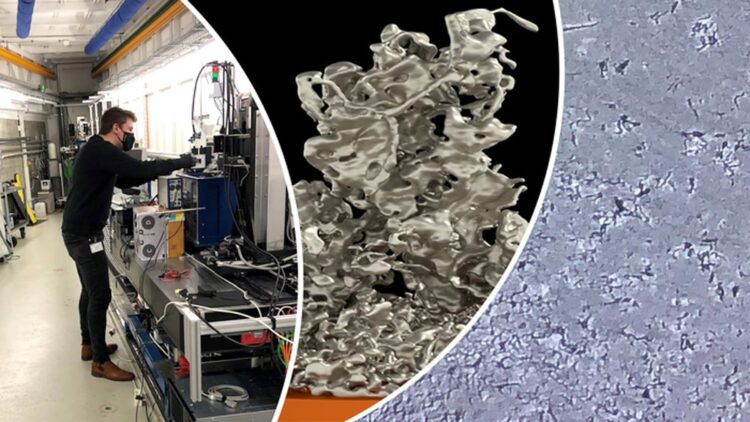

Battery researchers have long wanted to study lithium metal in a working lithium metal battery. Now researchers from Chalmers have developed a method to follow how the lithium in the battery cell behaves while cycling. With a specially designed cell and using X-ray tomographic microscopy, the researchers can observe the inner workings of the battery in real time in 3D. The new method may contribute to batteries with higher capacity and increased safety in our future cars and devices.

Credit: Chalmers University of Technology

Innovative battery researchers have cracked the code to creating real-time 3D images of the promising but temperamental lithium metal battery as it cycles. A team from Chalmers University of Technology, Sweden, have succeeded in observing how the lithium metal in the cell behaves as it charges and discharges.

The new method may contribute to batteries with higher capacity and increased safety in our future cars and devices.

“We’ve opened a new window in order to understand – and in the long term to optimise – the lithium metal batteries of the future. When we can study exactly what happens to the lithium in a cell during cycling, we gain important knowledge of what affects its inner workings,” says Aleksandar Matic, professor at the Department of Physics at Chalmers and head of the scientific study that was recently published in Nature Communications.

There are high hopes that new battery concepts, such as lithium metal batteries, will be able to replace today’s lithium-ion batteries. The goal is to develop more energy-dense and safer batteries that will take us further at a lower cost – both financially and environmentally. Solid-state batteries, lithium-sulphur batteries and lithium-oxygen batteries are among those being held up as promising alternatives. All of these concepts build on the idea that the battery anode, consists of a lithium metal instead of the graphite that is in today’s batteries. Without graphite, the battery cell will be lighter, and with lithium metal as the anode it will also be possible to use high-capacity cathode materials. This makes it possible to achieve three to five times the energy density.

Lithium forms undesired microstructures

However, lithium metal batteries have one crucial problem: when battery is charged or discharged, the lithium does not always deposit as flat and smooth as it should. Often, it forms mossy microstructures or dendrites, long needle like structures , and parts of the deposited lithium can become isolated and are then inactive. Dendrites, also risk reaching the other battery electrode and cause a short circuit. Therefore, it is crucial to understand when, how and why these structures form.

“To be able to use this technology in the next generation of batteries, we need to see how a cell is affected by factors such as current density, the choice of electrolyte and the number of cycles. Now we have a tool to do so,” says Chalmers researcher Matthew Sadd, head author of this new study along with his colleague Shizhao Xiong.

Excited wait for the first glimpse

The experiment to observe the formation of lithium microstructures in a working cell was conducted at the Swiss Light Source outside Zurich in Switzerland. In breathless anticipation, the researchers prepared a specially designed battery cell to study when lithium is deposited, in real time and in 3D using X-ray tomographic microscopy. Although many researchers have wanted to study lithium metal in a working cell, no one had been able to do so as far as the team knew. If they succeeded, it would be a major step forward, compared with analysing images after a cell has been cycled.

“It was magical when we saw with our own eyes that it worked on the first attempt,” Matic said. “When we observed the lithium creating big structures, like huge needles, it was almost like being in a lunar landing project. We’ve been wanting to observe the inner workings of batteries in real time for so long. And now we can.”

Key piece of the puzzle for large-scale use

Now the research team aims to test the technique on other battery concepts, hoping that the necessary imaging technology will be available closer to home, for example at the Swedish MAX IV lab, a national research facility for advanced x-ray experiments.

“We’re looking forward to developing this method to take faster measurements at higher resolution to see more detailed microstructures formed early on in the deposition process,” Matic says. “This is a key piece of the puzzle to be able to use lithium metal batteries on a large scale and make them safe. A lot of research teams and companies are looking at the lithium metal concept for their future prototypes.”

More about the research

- The article Investigating microstructure evolution of lithium metal during plating and stripping via operando X-ray tomographic microscopy was published in Nature Communications and was written by Matthew Sadd, Shizhao Xiong, Jacob R. Bowen, Federica Marone and Aleksandar Matic. The researchers work at Chalmers University of Technology in Sweden, Xnovo Technology ApS in Denmark and the Paul Scherrer Institute at the Swiss Light Source in Switzerland.

- The research was funded by Vinnova, the BASE excellence centre and Chalmers’ Energy Area of Advance.

- In collaboration with international colleagues, Aleksandar Matic’s research team at Chalmers has published several results on how lithium is distributed when lithium metal batteries are charged and discharged, such as Insight Into The Critical Role of Exchange Current Density on Electrodeposition Behaviour of Lithium Metal in Advanced Science and Role of Li‐Ion Depletion on Electrode Surface: Underlying Mechanism for Electrodeposition Behavior of Lithium Metal Anode in Advanced Energy Materials.

More about the batteries of today and the next generation of batteries

- In the search for the next generation of energy-dense, resource-conserving batteries, lithium metal batteries are one of the promising concepts. The hope is that the new battery type will replace today’s lithium-ion batteries, particularly in various types of electric vehicles. The goal is to develop energy-dense, safe batteries that will take us further at a lower cost – both financially and environmentally.

- In lithium-ion batteries, the lithium is stored in graphite, which itself does not contribute to the activity. In lithium metal batteries, the graphite is replaced with lithium metal, which makes the battery more energy dense. With lithium metal as the anode, it is also possible to use high-capacity cathode materials. This can result in batteries with three to five times the energy density of today’s batteries.

- Solid-state batteries, lithium-sulphur batteries and lithium-oxygen batteries are three examples of promising next generation battery concepts. All of these require lithium metal on the anode side to match the capacity of the cathode and maximise the energy density of the cell.

- So far, the researchers surmise that the breakthrough for the next generation of batteries is some ten years away.

- At Chalmers University of Technology, research is underway in a number of battery-related projects, and the researchers are involved in national and international collaborations, like the Swedish BASE excellence centre and the major European 2030+ BIGMAP project.

For more information, please contact:

Aleksandar Matic, Professor, Department of Physics, Chalmers University of Technology, +46 31 772 51 76, matic@chalmers.se

Matthew Sadd, Post doc, Department of Physics, Chalmers University of Technology, matthew.sadd@chalmers.se

Shizhao Xiong, Post doc, Department of Physics, Chalmers University of Technology, +46 76 218 49 51

Journal: Nature Communications

DOI: 10.1038/s41467-023-36568-z

Method of Research: Experimental study

Subject of Research: Not applicable

Article Title: Investigating microstructure evolution of lithium metal during plating and stripping via operando X-ray tomographic microscopy

Article Publication Date: 15-Feb-2023

COI Statement: The authors declare no competing interests.

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…