Sustainable aircraft

(c) Christian Bay

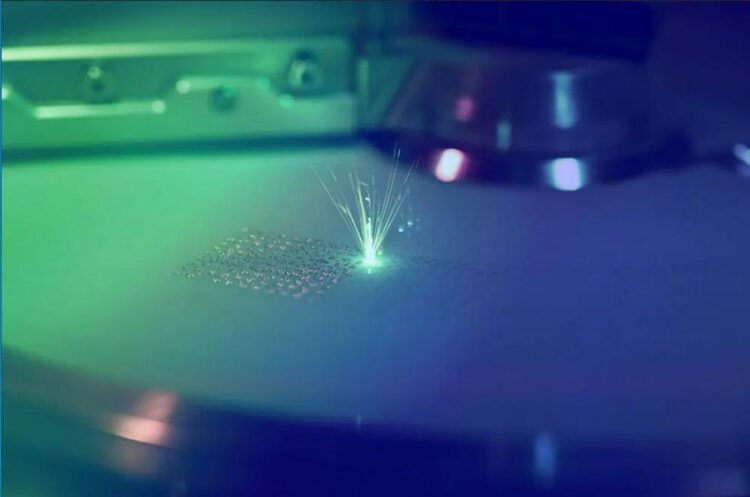

University of Bayreuth researches aircraft parts from the 3D printer.

The University of Bayreuth is contributing its expertise in additive manufacturing to a major European project: The EU is funding the Hybrid ElectriC regional Aircraft distribution Technologies (Hecate) project with more than 34 million euros, which aims to make aviation more environmentally friendly. The Chair of Environmental Production Technology at the University of Bayreuth is responsible for sustainable components in the project.

Air transport must meet the ambitious targets of the European Green Deal. This would require, for example, regional aircraft to be powered hybrid-electrically. This significantly reduces fuel consumption. This makes environmentally friendly and sustainable flying possible. The HECATE project, which is funded by the European Union with 34,210,348 euros, is now tackling the challenges of sustainable air transport. A total of 38 partners are involved in the project, which belongs to “Horizon 2.5.7. – Clean, Safe and Accessible Transport and Mobility”, including the University of Bayreuth.

“We are developing new components that are not only lighter, but also better,” explains Dr.-Ing Christian Bay, senior engineer at the Chair of Environmental Production Engineering and project manager of HECATE at the University of Bayreuth.

“Through the additive construction of the components, sensors can be incorporated, for example, and thus the functions of the components can be expanded.”

In this case, additive means that the components are created from special material mixtures using 3D printing.

The HECATE project is led by the Irish company Collins Aerospace. The project participants are located in twelve European countries and have different task pacts that, when combined, pursue the goal of “clean aviation”, i.e. environmentally friendly aviation. “In Bayreuth, we are working in the HECATE project on the production of sustainable additive components, which are of enormous importance for the overall project because they can be used to push back previous limits of functional and lightweight optimisation,” says Prof. Dr.-Ing. Frank Döpper, Chair of Environmental Production Technology at the University of Bayreuth. The University of Bayreuth will receive almost 700,000 euros from the European Union for this until the end of 2025.

In addition to the University of Bayreuth, the Fraunhofer Society for the Promotion of Applied Research, Diehl Aerospace GmbH, HS Elektronik Systeme GmbH and the Technical University of Ilmenau are also involved in the HECATE project in Germany.

Further information on Hybrid ElectriC regional Aircraft distribution Technologies can be found here: https://cordis.europa.eu/project/id/101101961

The expertise of the Bayreuth-based company in 3D printing was also recognised last year by the specialist platform All3DP.com. In an article, the magazine listed the “Top 10 University 3D printing Labs of 2022”. The Printing Lab at the University of Bayreuth is the youngest in this global ranking.

Funded by the European Union under GA No. 101101961 – HECATE. However, the views and opinions expressed are solely those of the author(s) and do not necessarily reflect those of the European Union or Clean Aviation. Neither the European Union nor the granting authority can be held responsible for them.

Wissenschaftliche Ansprechpartner:

Dr.-Ing. Christian Bay

Head of the Additive Manufacturing Working Group

Tel.: +49 (0)921 / 78516-226

E-Mail: christian.bay@uni-bayreuth.de

Media Contact

All latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

“Nanostitches” enable lighter and tougher composite materials

In research that may lead to next-generation airplanes and spacecraft, MIT engineers used carbon nanotubes to prevent cracking in multilayered composites. To save on fuel and reduce aircraft emissions, engineers…

Trash to treasure

Researchers turn metal waste into catalyst for hydrogen. Scientists have found a way to transform metal waste into a highly efficient catalyst to make hydrogen from water, a discovery that…

Real-time detection of infectious disease viruses

… by searching for molecular fingerprinting. A research team consisting of Professor Kyoung-Duck Park and Taeyoung Moon and Huitae Joo, PhD candidates, from the Department of Physics at Pohang University…