New Spatial Light Modulator for dynamic beam shaping

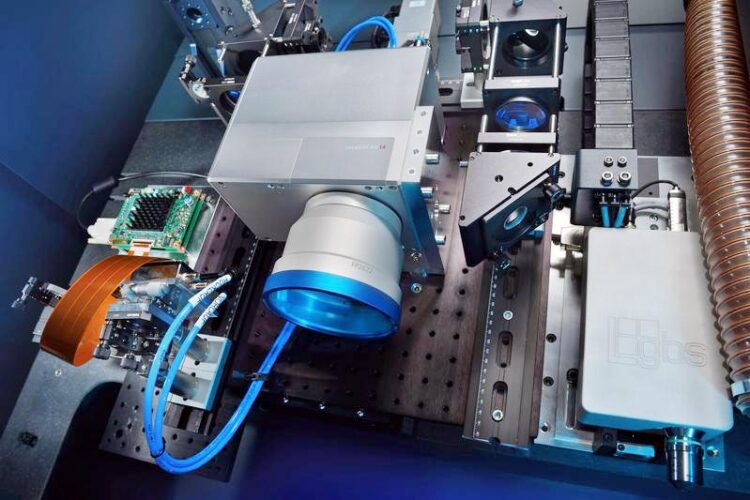

In the “Joint Application Lab” of Hamamatsu and Fraunhofer ILT, manufacturing processes can be investigated using a scanner-based process head with an integrated high-power SLM.

(c) Fraunhofer ILT, Aachen, Germany

… in industrial high-power USP processes.

Together with Hamamatsu, the Fraunhofer Institute for Laser Technology ILT in Aachen has set up an application lab for advanced laser material processing with ultrashort pulsed (USP) laser radiation. In Aachen, the partners jointly developed an industrial processing SLM-head that can use customized, dynamic beam shaping combined with large laser average output powers for a wide range of applications. The applied, new Spatial Light Modulator from Hamamatsu can be operated up to 150 watts of average output power.

Multi-beam systems are the key to scaling power, speed and costs

(c) Fraunhofer ILT, Aachen, Germany

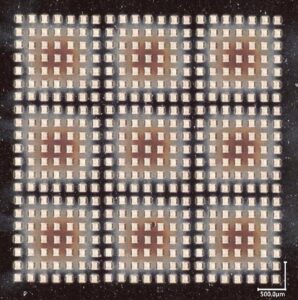

Ultrashort pulsed (USP) laser radiation can process virtually any material at the highest precision. To increase the economic benefit of USP processing, research uses different hardware approaches to address the handing of increased high average laser powers with more than 100 watts, thus, upscaling processing speeds and lower unit costs. One popular method to implement these large laser powers is to split the high-energy radiation into many individual beams. This approach is already being used industrially, particularly for two-dimensional laser material processing or for the generation of periodic patterns such as filters.

Phase masks are used to generate a parallelized beam patterns with a large number of partial beams from one incident beam. This works dynamically with spatial light modulators (SLM) or statically with diffractive optical elements (DOE) made of glass. SLMs can dynamically change the phase pattern and, thus, also the beam matrix, while static DOEs can withstand higher average powers.

SLMs are particularly suitable for developing manufacturing processes that use USP laser radiation since the beam properties can be easily adapted and tailored. This applies to both the beam profile as well as the arrangement of the individual beams within a pattern. In series production, SLMs are advantageous if beam patterns have to be changed dynamically during the process. If the beam parameters are known and static, DOEs are the better choice due to their insensitivity.

“Joint Application Lab” at Fraunhofer ILT

Together with the SLM manufacturer Hamamatsu, a “Joint Application Lab” has been set up at Fraunhofer ILT. There, an industry-ready prototype is ready for the development of manufacturing processes. This includes a scanner-based process head in which Hamamatsu’s new high-power SLM is integrated. The head is integrated into a 3-axis machine with a 150 W USP laser.

The new SLM has been optimized for high average power and is currently being introduced to the market. Hamamatsu received funding from the Japanese government to establish the new laboratory under the Cross-ministerial Strategic Innovation Promotion Program (SIP).

SLM enables high power in the application

In Aachen, the system with the new SLM has been in use for various processes and applications since May 2022. The team of Hamamatsu and Fraunhofer ILT has investigated the surface and volume ablation with different beam profiles and focus diameters. The flexible liquid modulator eliminates the need for tool changes.

The heat distribution in the workpiece has become increasingly important when large average laser powers are applied and USP processes are scaled in speed and efficiency. Thanks to the support of the Instruction and Research Department for Nonlinear Dynamics of Laser Manufacturing Processes (NLD) at RWTH Aachen University, Fraunhofer ILT has been able to simulate the processes completely. In this way, the energy distribution and, thus, the heat input within a parallelized beam distribution can be optimized.

In the “Joint Application Lab,” Fraunhofer ILT helps its customers to develop manufacturing processes. In addition, it also uses the know-how and technology it develops in new research projects.

Wissenschaftliche Ansprechpartner:

Martin Kratz M.Sc.

Micro and Nano Structuring Group

Telephone +49 241 8906-581

martin.kratz@ilt.fraunhofer.de

Dipl.-Phys. Martin Reininghaus

Group Leader Micro and Nano Structuring

Telephone +49 241 8906-627

martin.reininghaus@ilt.fraunhofer.de

Fraunhofer Institute for Laser Technology ILT

Steinbachstraße 15

52074 Aachen, Germany

Weitere Informationen:

https://www.ilt.fraunhofer.de/en.html

https://www.hamamatsu.com/eu/en.html

https://www.nld.rwth-aachen.de/cms/~gvyq/NLD/?lidx=1

Media Contact

All latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

Bringing bio-inspired robots to life

Nebraska researcher Eric Markvicka gets NSF CAREER Award to pursue manufacture of novel materials for soft robotics and stretchable electronics. Engineers are increasingly eager to develop robots that mimic the…

Bella moths use poison to attract mates

Scientists are closer to finding out how. Pyrrolizidine alkaloids are as bitter and toxic as they are hard to pronounce. They’re produced by several different types of plants and are…

AI tool creates ‘synthetic’ images of cells

…for enhanced microscopy analysis. Observing individual cells through microscopes can reveal a range of important cell biological phenomena that frequently play a role in human diseases, but the process of…