Build your own AI with ISAAC for error detection in production

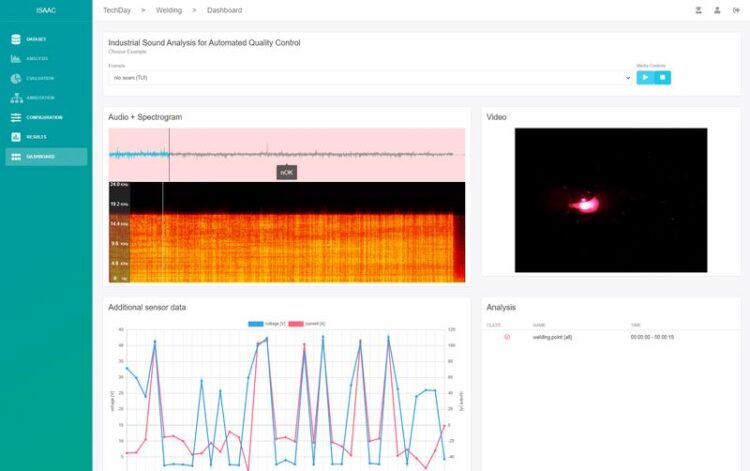

Live view of the multimodal sensor data included in the analysis.

Fraunhofer IDMT

Fraunhofer IDMT has developed a software tool for quality inspectors based on Artificial Intelligence (AI), which automates and simplifies the analysis of industrial sounds, for example in welding processes. Thanks to pre-built AI models, established methods for audio analysis and application-specific sensor data, companies can use it to improve their quality control decisively. Even without AI expert knowledge, statements can be made quickly and reliably regarding the quality of products and manufacturing processes during production and in the final quality inspection. The new software ISAAC will be presented at the virtual Fraunhofer trade fair, the “Fraunhofer Solution Days 2020”.

Talking about joining methods such as welding, an important part of the weld seam inspection has so far been the experienced welder himself, who can assess the quality of the weld seam by just listening to process-typical sounds. With the increasing automation of their production facilities, companies are increasingly relying on smart inspection software for quality control of manufacturing processes and industrial products.

By using AI, more precise analysis results are expected and a faster, more efficient and more cost-effective quality assurance is the main goal. However, how can the expert knowledge for the automated analysis of industrial sounds be transferred to the specific application in the company where AI actually brings the desired added value?

Using pre-trained AI models for own analyses

This is possible with the software “Industrial Sound Analysis for Automated Quality Control”, ISAAC, developed by Fraunhofer IDMT. Quality inspectors can use the pre-trained AI models from the field of acoustic sensor data analysis to adapt them to their own measurement data. This does not require in-depth knowledge of machine learning methods. Users import their sensor data easily and securely into the software. With an intuitive interface, users can then try out, edit, and apply pre-built AI models included in the framework to their own acoustic test tasks.

Depending on the application, the well-arranged data view provides an overview of the sensor data involved in the analysis and helps with further analysis settings. The BMBF-funded research project “AkoS – Acoustic inspection of weld seams of safety-critical components as part of quality assurance” is currently investigating the extent to which information from acoustic sensors can be used for quality assurance purposes applying machine-learning methods. The research results obtained here are directly incorporated into the further development of ISAAC.

Direct integration into existing test software

Users can directly integrate ISAAC into the company-specific testing software. In addition to the analysis of acoustic data, information of other sensors, such as engine current data or optical sensor data, can also be included in the analysis. In the institute’s current research activities one further task is to compress the self-trained algorithms where they fit on mobile devices with less storage and computing power but still deliver reliable results at the same performance. For further development of the new software tool, Fraunhofer IDMT is looking for interested industry partners.

Technical information on ISAAC

• Import of acoustic time signals in various formats, e.g. as wave-file

• Configuration of specific extraction and model parameters

• Automatic pre-selection of suitable audio analysis tools and AI models

• Export of the created models for test hardware and software

• Detailed analysis results

• Hosted by Fraunhofer IDMT with secure data location

• Server software for internal operation

Register free of charge for the Fraunhofer Solution Days and learn how ISAAC improves quality control in manufacturing at the virtual booth of Fraunhofer IDMT. You will find our booth in the topic area “Plant and Mechanical Engineering”.

https://www.ubivent.com/register/Fraunhofer-Solution-Days-2020-EN

Besides ISAAC, you get to experience two other exciting exhibits as well as two expert presentations at the Fraunhofer Solution Days:

VIPRA – Auralisation of virtual products

VIPRA is a modern tool for digital product development that makes the sound of virtual products a realistic spatial experience – long before a first prototype is built. Acoustic properties and their effects can be assessed in early phases of prototyping and changes in material and design can be made.

The hearable for the smart industrial workplace

On the one hand, the “intelligent button in the ear” can act as hearing protection for noisy production environments, and on the other hand it enables crystal-clear and secure employee communication thanks to AI-based noise selection. In conjunction with solutions for robust speech recognition and acoustic event detection, additional options for human-technology interaction can be integrated into the Hearable, such as voice control of machines or contactless documentation. An acoustic monitoring of processes, e.g. for the documented and reliable engagement of connectors, can also be integrated. The highest data protection standards are ensured by local data processing.

Presentation:

“Audio is the new video. Acoustic and AI solutions for production.”, Univ.-Prof. Dr.-Ing. Joachim Bös, M.S./SUNY

October 26, 2020 I Auditorium I 2.30 pm – 3.00 pm

Acoustics play an increasingly important role in the product development process – whether in product development, during the production process or in final inspection. The lecture will present practical acoustic and AI technologies for industrial production along the value chain.

Presentation:

“The EEG-Lab to go”, Dr.-Ing. Insa Wolf

October 28, 2020 I Auditorium I 12.00 pm – 12.30 pm

In the future, the “EEG lab to go” will enable the recording of brain activity outside the laboratory over longer periods of time, thereby advancing the acquisition of new findings, e.g. on sleep disorders or epilepsy. The reduction of signal artifacts in data analysis and a high level of hardware comfort are central challenges in this context.

https://www.idmt.fraunhofer.de/en/events_and_exhibitions/fraunhofer-solution-day…

Wissenschaftliche Ansprechpartner:

Judith Liebetrau

Telephone: +49 3677 467-379

E-Mail: judith.liebetrau@idmt.fraunhofer.de

Weitere Informationen:

https://www.idmt.fraunhofer.de/en/institute/projects-products/isaac-industrial-s… More info and demo video of ISAAC

Media Contact

All latest news from the category: Information Technology

Here you can find a summary of innovations in the fields of information and data processing and up-to-date developments on IT equipment and hardware.

This area covers topics such as IT services, IT architectures, IT management and telecommunications.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…