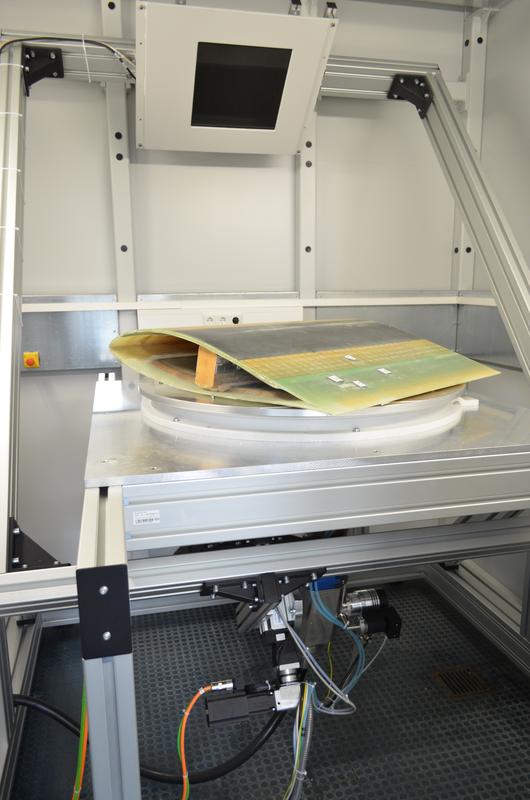

Production-integrated inspection of large-scale CFRP components

CLARA<sup>®</sup>: Computer Laminography and radiography system Fraunhofer IZFP

In lightweight construction or in aviation application of fiber-reinforced plastics (FRP) is steadily rising. FRP components are often used in form of very large or flat shapes, which can be examined using the Fraunhofer IZFP’s CL device CLARA® (Computer Laminography and radiography system). As nondestructive inspection of complex components and materials is increasingly required along the entire material cycle but especially during the production process, the development of new, time-saving and cost-effective testing methods is essential.

CT as a widespread X-ray method can obtain high-resolution 3D volume images to depict the finest structures and details. But considering in particular objects, where CT is unsuitable, CL is an efficient and effective alternative. “While in medicine CL is widely used, industrial applications are seldom to found despite some outstanding advantages compared to CT”, Dr. Michael Maisl explains, senior scientist and group manager of the “Reconstruction, Image Processing, CT/CL by X-ray” group at Fraunhofer IZFP.

Unlike CT, CL is perfectly suited for high-resolution inspection of large or planar components. Compared to CT, the inspection time can be significantly reduced. Additionally, a variety of different recording shapes is available, which also enable adjustments to perform fully automated batch inspection.

Similar to CT, radiographs are taken from different angles to compute a three-dimensional representation of the object’s internal structure using a reconstruction algorithm.

Unlike CT, however, the rotation axis is not orthogonal, but inclined to the beam direction. “By this inclination the otherwise inevitable collision between the object and the source or the detector can be avoided. The arrangement ensures the penetration of the object covering any necessary irradiation angles. As a consequence the individual section planes can be reconstructed at any relevant resolution and represented adequately, “Maisl adds.

Traditionally, CL is used for the examination of electronic circuit boards. Recent application areas are related to modern lightweight materials such as fiber reinforced plastics (CFRP, GFRP), which are increasingly common, also in the form oversized parts for wind turbines or in automobile industry and in aviation. Further applications concern the defect inspection of parts or components, e.g. the detection of porosities or inclusions in car body parts or the detection of micro-cracks in photovoltaic modules.

Media Contact

All latest news from the category: Trade Fair News

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…