Functional films and efficient coating processes

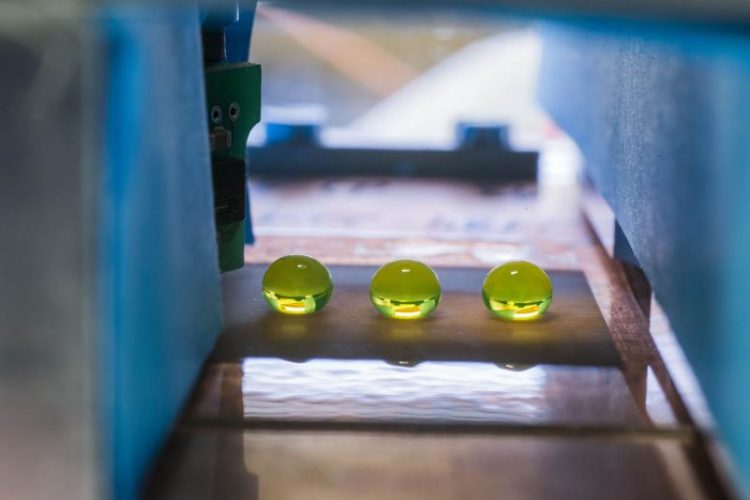

Fraunhofer scientists study how anti-icing coatings affect the freezing behavior of water droplets in an icing chamber © Photo Fraunhofer IGB

Control and monitoring of coating processes inline – for the first time

The development of a cost-effective, optical measuring system means that coating processes will in the future be able to be fully controlled and monitored over the entire substrate surface. The inaugural presentation of this new system developed by the Fraunhofer IAP and the Fraunhofer IVV will take place at ICE Europe 2017.

The degree of crosslinking and thickness of organic coatings can be controlled inline via automated coupling of the measurement system to the coating unit. This prevents issues such as delamination, poor processing of web-shaped materials, and increased migration of non-crosslinked adhesive components.

Accelerated test methods for high-barrier films

High-barrier laminates manufactured in roll-to-roll processes for the encapsulation of flexible solar cells and electronic components must have as low as possible oxygen and water vapor permeabilities. For quality assurance, it is a challenge to measure the permeability of such films over long periods of time.

The tests can take several months. Now, however, the Fraunhofer IVV has developed a device for measuring the permeability of ultra barrier films in combination with associated computer software for simulating the permeation process. This enables the water vapor permeability to be determined 3 to 4 times faster than with conventional methods.

Further improvement of high barrier technology using atomic layer deposition

The Fraunhofer IVV has acquired a new coating plant which utilizes atomic layer deposition to further reduce the permeability of films. Minimizing the permeability to water vapor and oxygen is the key to successful further improvement of high barrier films. Atomic layer deposition (ALD) is paving the way here. Coating via roll-to-roll processes allows high processing speeds and production efficiency to be achieved. Up until now, films with the highest barriers have been produced exclusively in vacuum processes.

The new ALD plant at the Fraunhofer IVV enables the barrier properties of films to be significantly improved. This is a further step towards meeting the permeability requirements for OLED encapsulation in the medium term. The Fraunhofer IVV is using this technology for publicly funded R&D projects and to provide industry with customized solutions and research services for the development of processes and materials.

Anti-icing films reduce damage caused by ice

The formation of ice on the rotor blades of wind turbines results in aerodynamic imbalance. In order to prevent damage, either the rotor blades must be heated or the wind turbine must be shut down. To tackle this issue, the Fraunhofer IGB has developed a number of anti-icing coatings suitable for polymer surfaces. These water-repelling microstructured and nanostructured coatings ensure that any water remains a liquid, even at temperatures below zero, resulting in a 90% reduction in ice adhesion compared to uncoated surfaces.

The trick: The surfaces provide the water molecules with no crystallization nuclei. Plasma technology is used to deposit the structured coatings onto plastic films made of impact-resistant polyurethane (PU). The coatings are not only of interest for wind turbines: these functional surfaces can also be applied to aircraft wings and solar panels. Furthermore, anti-icing coatings can also be directly applied to fabrics and plastics, for example for winter sports clothing, tents, and other outdoor articles.

Easy cleaning – printable films – water-repelling textiles

Regardless of whether the requirement is for anti-fouling and easy-to-clean surfaces, printable films, or eco-friendly water-repelling textiles, the Fraunhofer IGB usually uses plasma processes to create these new surface properties. Plasma processes allow the top layers to be removed, so generating pristine surfaces and enabling chemical functionalities or other layers to be applied.

Selection and control of the chemical processes enable the scientists at the Fraunhofer IGB to customize the surface energy and hence the wetting properties. This enables even textiles to be effectively equipped with water-repelling or oil-repelling properties – in an eco-friendly way without harmful byproducts or waste products.

“Intelligent” materials via roll-to-roll processes

Whilst the properties of most synthetic materials are fixed, many biological systems have the ability to adapt to changing environmental conditions. Materials are, however, now being developed with properties which “change” on exposure to external stimuli. These so-called “intelligent” materials change, for example, when exposed to various physical and chemical stimuli such as temperature, light intensity, and pH or due to biomolecules such as proteins. This is being achieved using special polymers developed by the Fraunhofer IAP.

This development work is being supported by surface technologies which allow even these intelligent materials to be manufactured on a large scale in roll-to-roll processes. In addition to classical methods such as corona and plasma treatment, printing methods (entire surface or structured) are widely used for the functionalization of surfaces.

Media Contact

All latest news from the category: Trade Fair News

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…