Full speed ahead for SmartEEs at Automotive Interiors Expo 2019

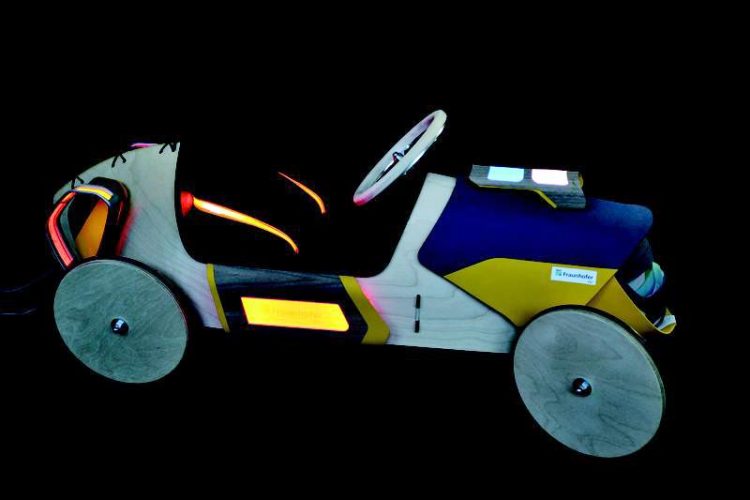

Concept study for the use of flexible OLEDs for automotive applications © Fraunhofer FEP | Picture in printable resolution: www.fep.fraunhofer.de/press

It surrounds us and almost unconsciously accompanies us through everyday life – printed electronics. It starts with smart labels or RFID tags in clothing, we come across test strips for blood glucose measurement or while gripping in the refrigerator in the form of labels or anti-counterfeiting protection on packaging.

The day continues with many looks at the mobile phone with OLED display or the Smart Watch on the arm. On the way to work, sensors monitor seat occupancy detection, touch displays support navigation, and OLED tail lights light up the car to say goodbye when you arrive at your destination.

The market for printed electronics and flexible organic electronics has been growing continuously for years. Growth forecasts are particularly high for the thin-film, organic and large-area electronics (TOLAE) market, in which Europe has a strong research and innovation position.

This offers great opportunities for European industry. So far, however, European small and medium-sized enterprises have had very limited access to these technologies and have not been able to build up and develop the skills to use them to benefit from them.

Starting with a broad knowledge base to convert the TOLAE technologies into own ideas and innovative products, to open up potential markets and finally to build up a long-term functioning network of partners in order to jointly use the possibilities of the technologies within the companies.

This is where the European project SmartEEs – Smart Emerging Electronics Servicing, launched some two years ago, starts. It offers an organized European innovation network for access to competences and technologies for printed and thin film electronics and beyond that support for the implementation of innovations up to commercialization.

One of the most important pioneering industries to have included flexible organic electronics in their future programs and innovation roadmaps is the automotive industry. The lighting designers of the leading European automotive manufacturers now use flexible light sculptures made of OLEDs to create accents and statements for these technologies in their products and cars.

With their possibilities such as segmentation, signage, color variability, transparency and light weight, flexible OLEDs offer new design worlds, e.g. on plastic or ultra-thin glass. Flexible touch panels, curved displays and printed sensors are also a must-have.

The Fraunhofer FEP has more than 10 years of experience in research and development of flexible organic electronics and their integration into later applications in various industries. Especially the focus on always application-oriented research and customer-specific solutions matching the requirements of industry and SMEs predestines the Fraunhofer FEP as a partner in this European innovation hub. Dr. Christian May, Head of Business Unit Flexible Organic Electronics, explains the role of Fraunhofer FEP and its portfolio:

“What began with the first rigid luminous surfaces, our scientists have now been able to establish to a broad-based competence center for flexible organic electronics. In addition to the development of flexible OLEDs in sheet-to-sheet processes, we also have the possibility of cost-efficient technology development of OLEDs in roll-to-roll processes. In the meantime, we can proudly look back on a large number of pioneering projects with the automotive industry, which have enabled us to build up very extensive know-how in the development of organic components and OLED lighting solutions precisely for this industry. This has also led us to a joint development project for OLED integration in automotive interiors as part of SmartEEs. In the future we of course hope to be able to contribute our expertise to other interesting projects as part of the network”.

How exactly does the SmartEEs construct work? In addition to the dissemination of TOLAE technologies, concrete application projects are selected and implemented to demonstrate the transfer of technologies into new products, processes and business models. A Digital Innovation Hub (DIH) was created as a platform for this purpose. This ecosystem consists of the technology services of the technology providers, which are linked with services from the areas of product development, business support and financing support.

These are implemented and offered as a 1-stop shop in order to realize the transfer of TOLAE technologies into the economy. The DIH can organize the provision of innovation funding to accelerate the industrial and societal introduction of new digital products, services and business models that realize the potential of applications with advanced organic photovoltaics, flexible displays, OLED lighting and integrated smart systems. A total of 4.5 million euros are available for this purpose, which SmartEEs are planning to invest in 20 application projects. Ideas for innovative projects by SMEs have already been submitted via the previous 4 cut-off dates and will be allocated and processed by the project partners.

Meanwhile, the 10 project partners can look back on the Half-Term of the project. SmartEEs coordinator Jérôme Gavillet takes stock: “So far, 8 interesting projects on thin-film and printed electronics and also on the development and integration of flexible OLEDs in new materials for a wide variety of industries such as logistics, health or sports have been handled by the SmartEEs partners. The results achieved show that the hub concept of the EU project is taking effect.

The next and last cut-off date is 20 September 2019, when innovative companies can again submit project ideas to the consortium.” All SMEs and start-ups from both technical and traditional sectors with innovative ideas for new applications in a wide variety of areas such as automotive, architecture, electronics, energy, lighting, logistics, medicine, packaging, printing or design, fashion and many more can apply for projects within SmartEEs.

The project partners and the consortium will jointly present the technologies of the individual partners and the joint project at Automotive Interiors Expo 2019 in Stuttgart, Germany, from 21 to 23 May 2019, with a SmartEEs joint booth no. A4557, in Hall 4.

SmartEEs at Automotive Interiors Expo 2019:

Joint booth:

No. A4557, Hall 4

Messe Stuttgart, Germany

Talk:

Wednesday, 22 May 2019, 2.00 – 3.40 pm, Hall 4

“SmartEEs – accelerating the uptake of flexible electronics”, Fraunhofer FEP for SmartEEs

SmartEEs Consortium:

Commissariat a l´Energie Atomique et aux Energies Alternatives, CEA, France

Centre for Process Innovation Limited, CPI, United Kingdom

Nederlandse Organisatie voor Toegepast Natuurwetenschappelijk Onderzoek TNO, The

Netherlands

Teknologian tutkimuskeskus VTT Oy, VTT Finland

Fundacio Eurecat; Spain

Fraunhofer FEP, Germany

Interuniversitair Microelectronica Centrum IMEC, Belgium

Blumorpho SAS, France

European and Business Innovation Centre Network AISBL, Belgium

Amires Sro, Czech Republic

Press contact:

Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP

Winterbergstraße 28 | 01277 Dresden, Germany | www.fep.fraunhofer.de

Head of Marketing: Ines Schedwill | Phone +49 351 8823-238 | ines.schedwill@fep.fraunhofer.de

Head of Corporate Communications: Annett Arnold, M.Sc. | Phone +49 351 2586-333 | annett.arnold@fep.fraunhofer.de

Media Contact

More Information:

http://www.fep.fraunhofer.de/All latest news from the category: Trade Fair News

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…