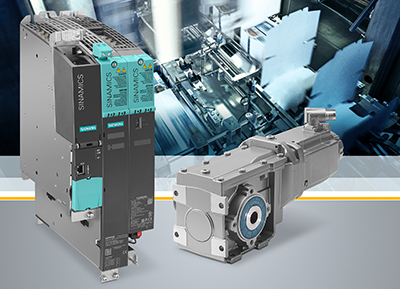

Flexible servo drive system for demanding applications

- New Simotics S-1FG1 servo geared motor with finely graduated transmission ratios

- Sinamics S120 converter with a wide range of technology functions and modified motor modules

- Optimal interaction of components simplifies

Siemens has expanded its extensive drive portfolio for servo applications to include the Simotics S-1FG1 servo geared motor that is optimally harmonized with the Sinamics S120 converter system. The complete integration of this drive system into Totally Integrated Automation (TIA) makes configuration and commissioning easy. Prefabricated Motion Connect signal and power cables offer an easy and reliable method of connecting the components. The components have electronic rating plates, and the motors are connected via the Drive-Cliq system interface so that the system can be brought into operation quickly. This servo drive system from Siemens is suitable for use in a multitude of applications, such as printing and packaging machines, storage and retrieval machines , conveyor systems and dosing pumps.

The highlights of the compact Simotics S-1FG1 servo geared motor are its high efficiency and low torsional backlash for precise, dynamic motion sequences. The Simotics S-1FG1 is available in the following versions: helical, parallel shaft, bevel and helical worm gearboxes – and with up to 25 transmission ratios, depending on the type of gear and size. The helical gearing of the gear wheels makes the gearboxes run very quietly, thereby reducing the generation of noise. The small diameter of the plug-on pinion inserted into the motor shaft enables the first gear stage to have a high transmission ratio. This in turn means that in some cases a two-stage gearbox can be used instead of a three-stage one.

On account of its highly integrated functionality and scalable number of axes, the Sinamics S120 converter system is suitable for use in a multitude of demanding Motion Control applications. The high-performance single and coordinated multi-axis drives with vector or servo control enable tailor-made solutions to be implemented that increase productivity and flexibility. The converter is available in four different versions: blocksize, booksize, chassis and cabinet units. The power units or motor modules in booksize format have been redesigned in the three to 30 ampere range. Power units with a treble overload capability and the integration of the motor connection system into the motor module save a considerable amount of space in respect of height and width in the control cabinet. The newly developed connection method makes for fast, easy and reliable assembly and wiring. The optimized shielding design and improved thermal separation between power semiconductor and electronics also ensure greater ruggedness.

You will find more information on the topic of servo drive systems at

www.siemens.com/sinamics

Siemens AG (Berlin and Munich) is a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for more than 165 years. The company is active in more than 200 countries, focusing on the areas of electrification, automation and digitalization. One of the world's largest producers of energy-efficient, resource-saving technologies, Siemens is No. 1 in offshore wind turbine construction, a leading supplier of combined cycle turbines for power generation, a major provider of power transmission solutions and a pioneer in infrastructure solutions as well as automation, drive and software solutions for industry. The company is also a leading provider of medical imaging equipment – such as computed tomography and magnetic resonance imaging systems – and a leader in laboratory diagnostics as well as clinical IT. In fiscal 2014, which ended on September 30, 2014, Siemens generated revenue from continuing operations of €71.9 billion and net income of €5.5 billion. At the end of September 2014, the company had around 343,000 employees worldwide on a continuing basis.

Further information is available on the Internet at www.siemens.com

Reference Number: PR2015100005DFEN

Contact

Mr. Peter Jefimiec

Digital Factory Division

Siemens AG

Gleiwitzer Str. 555

90475 Nuremberg

Germany

Tel: +49 (911) 895-7975

peter.jefimiec@siemens.com

Media Contact

All latest news from the category: Trade Fair News

Newest articles

“Nanostitches” enable lighter and tougher composite materials

In research that may lead to next-generation airplanes and spacecraft, MIT engineers used carbon nanotubes to prevent cracking in multilayered composites. To save on fuel and reduce aircraft emissions, engineers…

Trash to treasure

Researchers turn metal waste into catalyst for hydrogen. Scientists have found a way to transform metal waste into a highly efficient catalyst to make hydrogen from water, a discovery that…

Real-time detection of infectious disease viruses

… by searching for molecular fingerprinting. A research team consisting of Professor Kyoung-Duck Park and Taeyoung Moon and Huitae Joo, PhD candidates, from the Department of Physics at Pohang University…